Die casting furnace system with ultrasonic unit for improved molten metal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

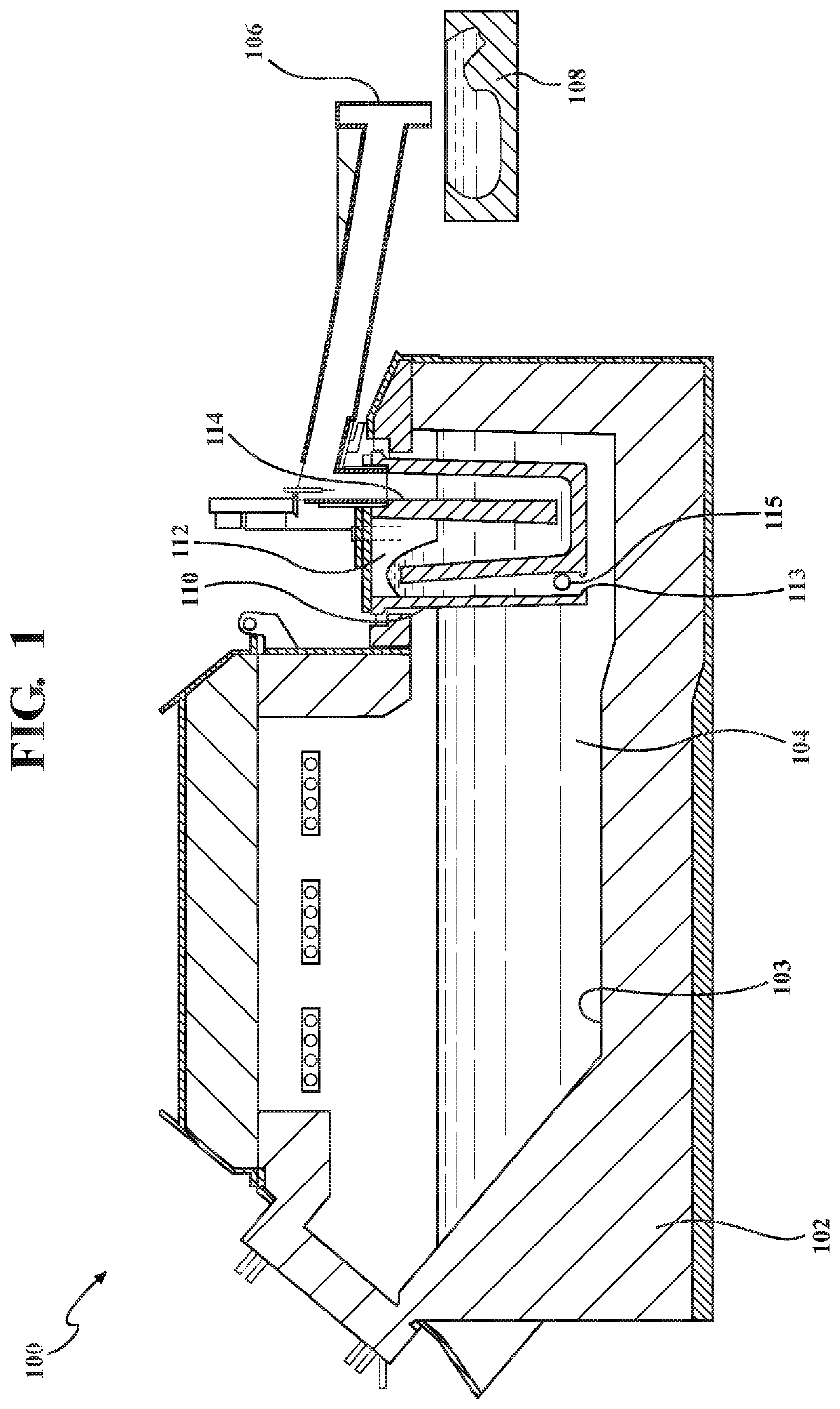

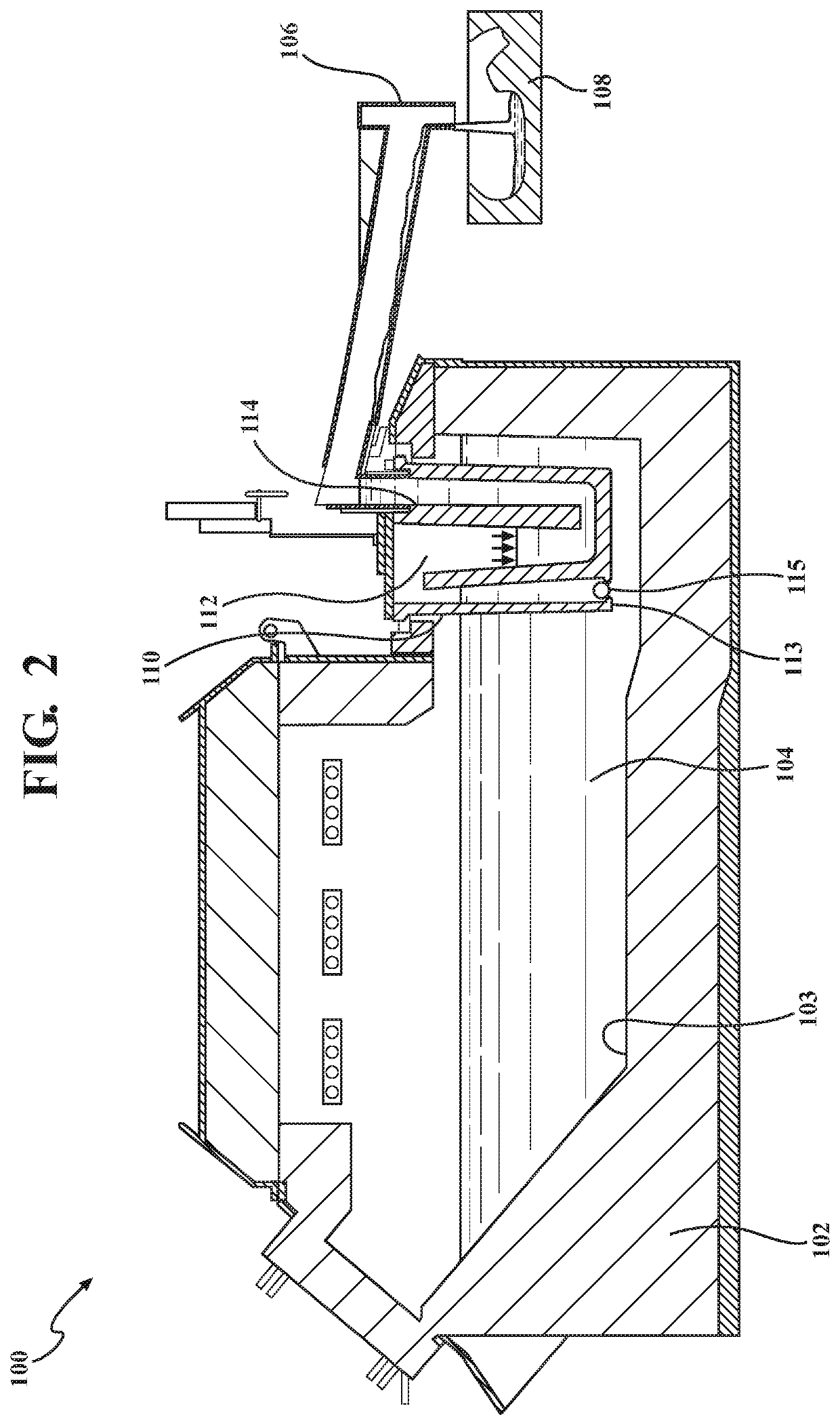

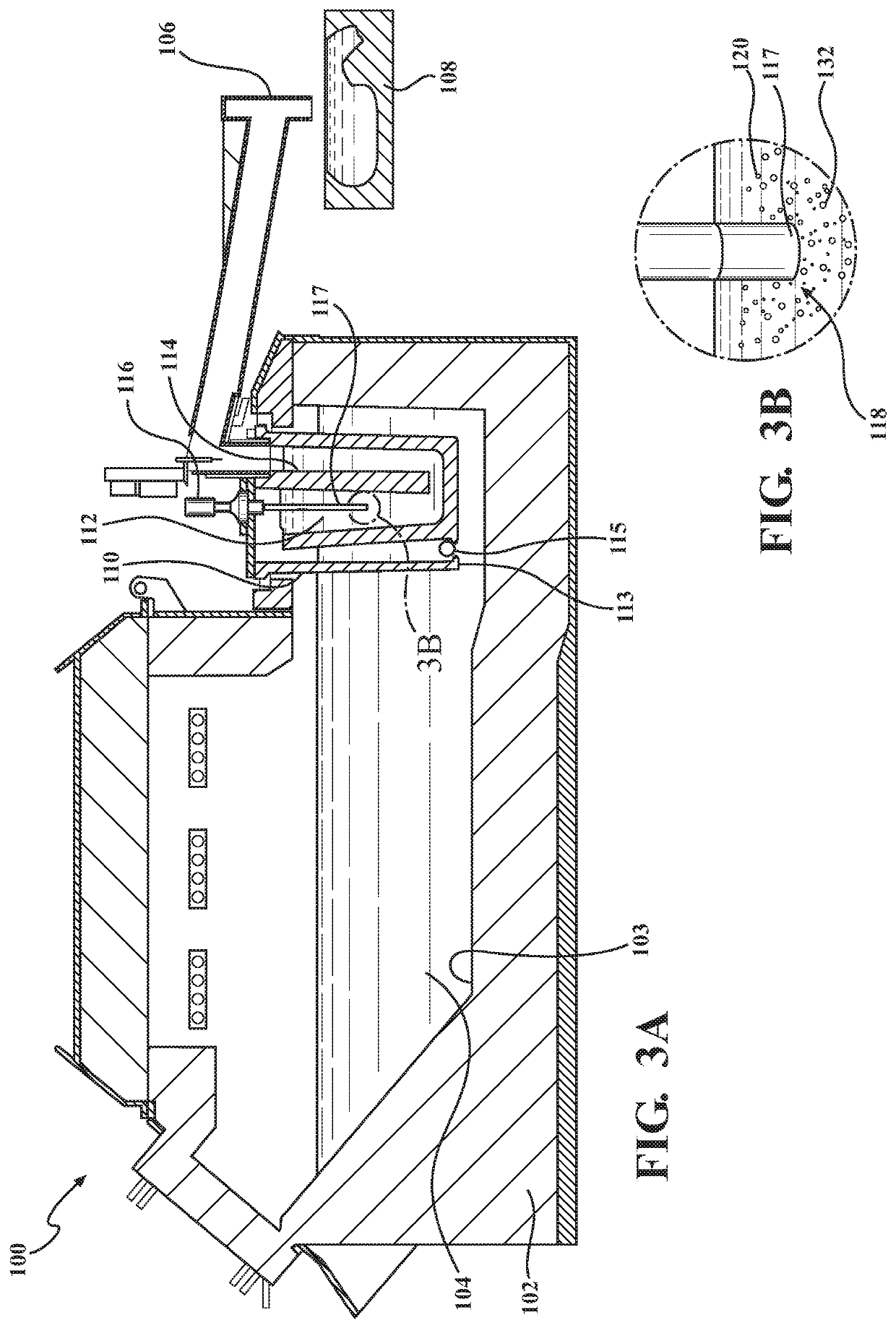

[0017]Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, a die casting holding furnace system 100, known as a dual chamber furnace, is generally illustrated in FIGS. 1-5. The die casting holding furnace system 100 includes a die casting holding furnace unit 102 defining a cavity 103 having a first storage capacity for holding a molten metal or molten material 104. The molten metal 104 may include aluminum, Al—Si—Mg alloy (300 series aluminum), or other metal or alloys. Furnace unit 102 is a closed holding furnace with a launder system to a die casting machine shot sleeve 106 for dispensing molten metal 106 from the die casting holding furnace unit 102 through the shot sleeve 104 to a die casting machine 108.

[0018]A dosing unit 110 is disposed or positioned within the cavity 103 and defines a dosing area 112 disposed in fluid communication with the cavity 103 for receiving the molten metal 104 during a refilling cycle. For examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com