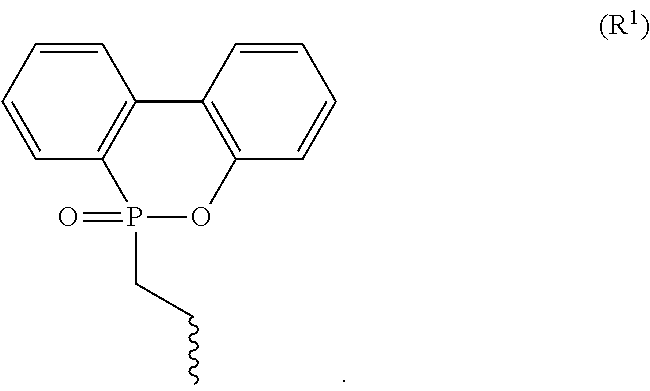

Additive phosphorus-containing polysiloxane compound for thermosetting resins, flame retardant composition comprising same, and articles made therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

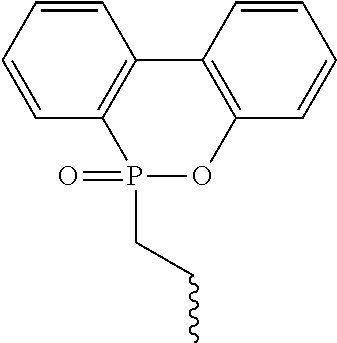

of DOPO-Siloxane

[0078]10-(2-trimethoxysilyl-ethyl)-9-hydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO-H) (432.4 g, 2.0 mol) and vinyltriethoxysilane (VTES) (399.7 g, 2.1 mol) were mixed together. The suspension was heated to 120° C. and formed a heterogeneous solution (molten DOPO—H layer on the bottom). t-Butyl peroxide (4 mL) was added dropwise into the reaction mixture within 30 min, tiny bubbles generated when peroxide reached the solution, and a homogeneous solution formed in a short time. The mixture was stirred at 120° C. for another 2 hours. At the end of the reaction, 31P NMR showed that less than 1 mol % of DOPO-H was left. The product DOPO-triethoxysilane (DOPO-TES) is a clear liquid. 31P NMR (121 MHz, CDCl3, ppm) δ 40. 1H NMR (300 MHz, CDCl3, ppm) δ 7.0-8.0 (m, 8H), 3.3-3.5 (m, 9H), 1.8-2.3 (m, 2H), 0.6-1.1 (m, 2H).

[0079]3.3 g of methanol, 0.6 g of water and 2.0 g of acetic acid were mixed together and added into 12 g of DOPO-TES dropwise over 15 min at 0° C. The reacti...

example 2

of DOPO-Siloxane

[0080]DOPO-Siloxane was prepared using procedures in Example 1. The product was then heated at 165° C. for 2 h to fully react any left-over Si—OH groups. After heating, the TGA 95 wt % is at 359° C.

example 3

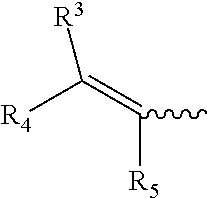

of DOPO-Vinyl-Siloxane

[0081]DOPO-TES was prepared using procedures in Example 1. 3.3 g of methanol, 0.6 g of water and 2 g of acetic acid were mixed together and added into a mixture of 10 g of DOPO-TES and 1.3 g of VTES dropwise over 15 min at 0° C. The reaction mixture was stirred at 100° C. for 4 hours. The solvent was removed and the product is a white foam. 31P NMR (121 MHz, CDCl3, ppm) δ 37-42 (product). 1H NMR (300 MHz, CDCl3, ppm) δ 7.0-8.0 (m, 8H), 5.3-6.0 (m, 1.8), 1.8-2.3 (m, 2H), 0.6-1.1 (m, 2H). The ratio between DOPO- and vinyl-groups is determined to be 5:3 based on the proton NMR. The product was then heated at 150° C. for 2 h to fully react any left-over Si—OH groups. After heating, the TGA 95 wt. % is at 318° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com