Press molding device and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

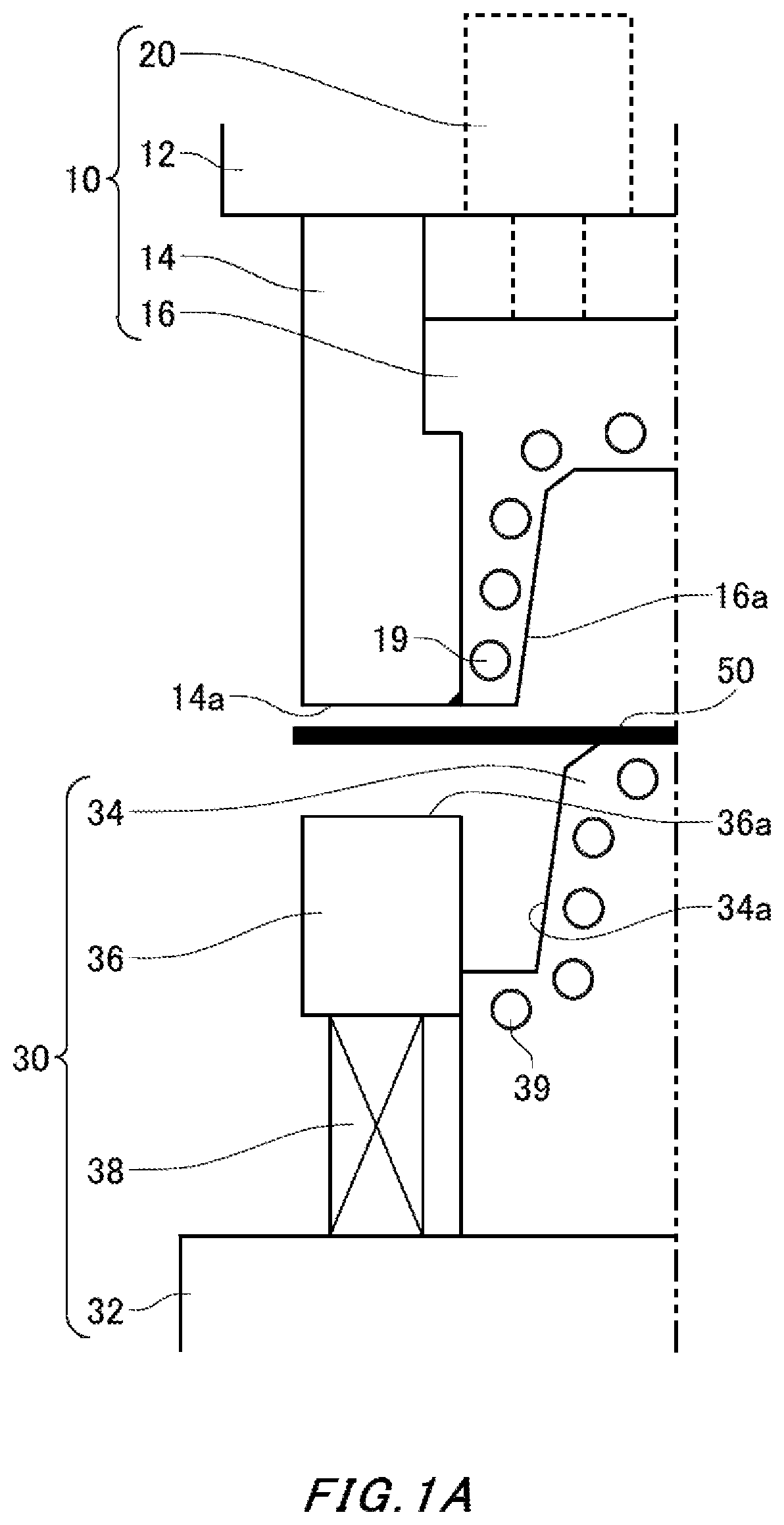

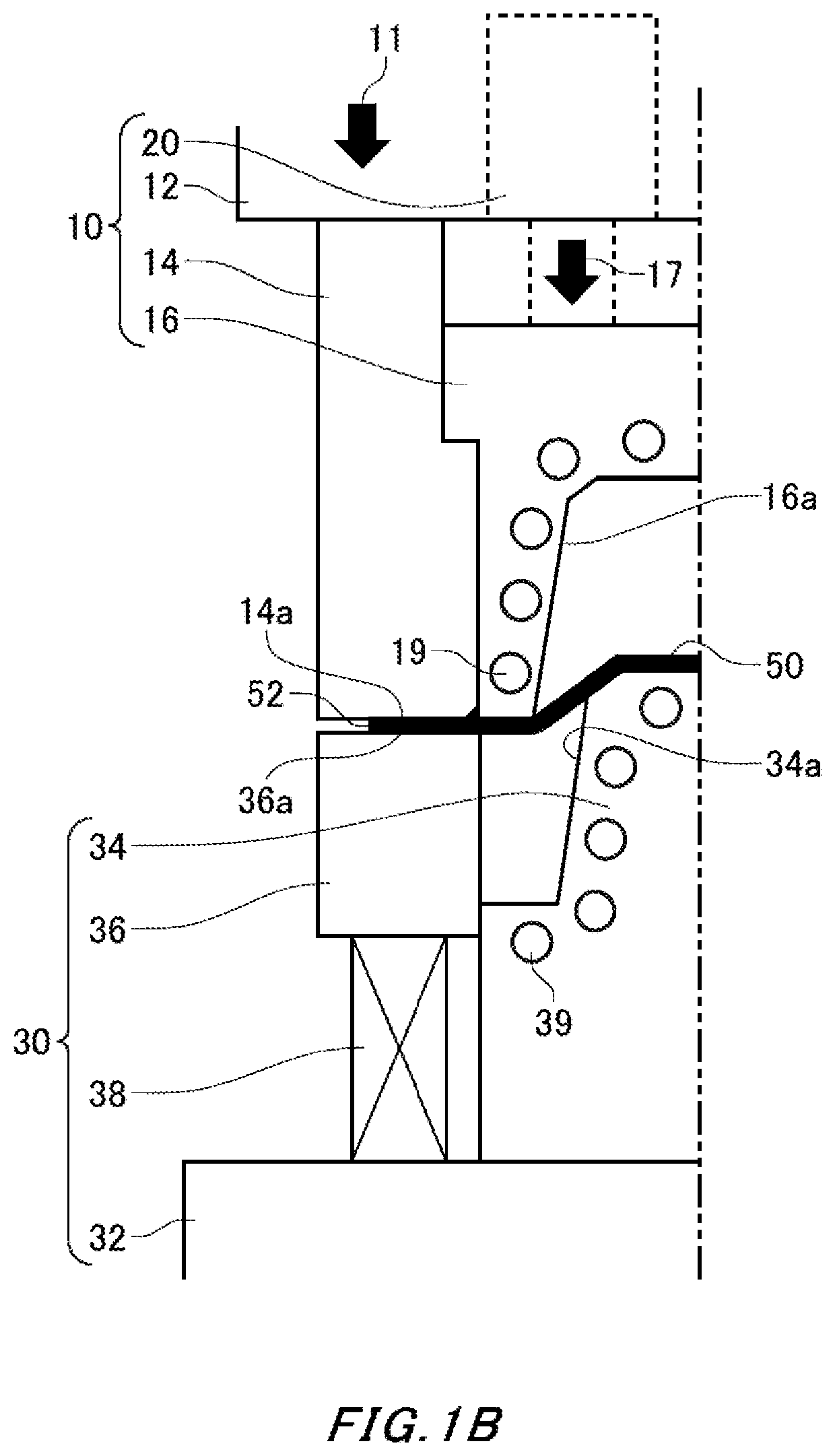

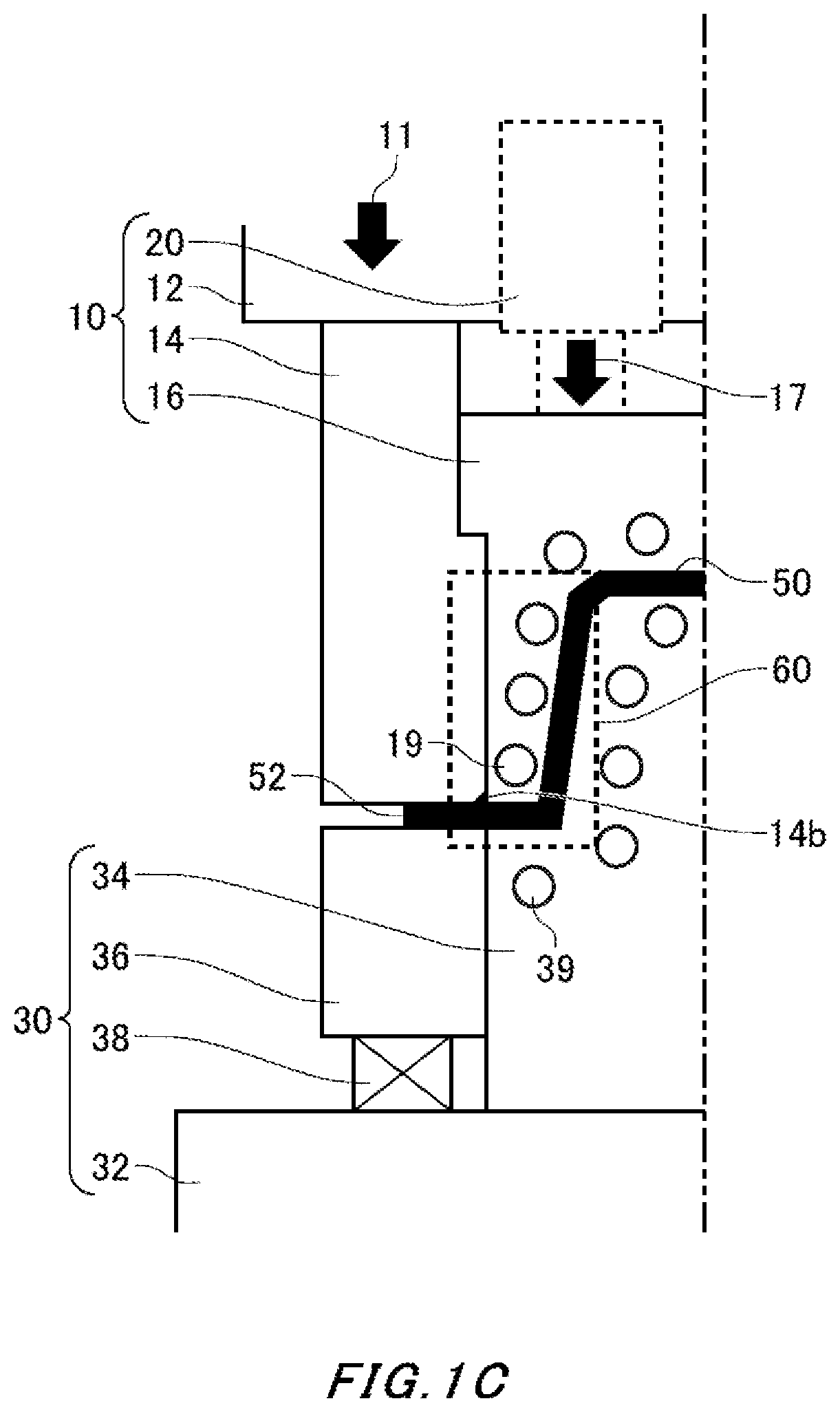

[0024]Hereinafter, the present invention will be described through the embodiments of the invention, but the following embodiments do not limit the invention according to the claims. Moreover, not necessarily all combinations of features described in the embodiments are essential to the solution of the invention.

[0025]In a hot stamp molding (also referred to as hot press molding, PHS or the like), one possible solution is to cool the press-molded article to have an strength equivalent to 1500 MPa, and then cut thus cooled press-molded article. However, a portion of the press-molded article that has been cooled and then cut has a high strength (hardness) and residual stress, and thus, there is a possibility that a delayed fracture occurs. In order to prevent such delayed fracture, it is considered to cut the work piece in the high temperature condition before being cooled. As a result, the strength (hardness) and the residual stress of the press-molded article are lowered, and thus, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moldable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap