One Trip Bottom Hole Assembly and Method for Milling Casing and Directionally Drilling a Lateral Wellbore

a lateral wellbore and one-trip technology, applied in the direction of drilling machines and methods, drilling holes/well accessories, directional drilling, etc., can solve the problem that cutting a window may require multiple trips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]In the following description of representative embodiments and examples of the claimed subject matter, like numbers refer to like parts.

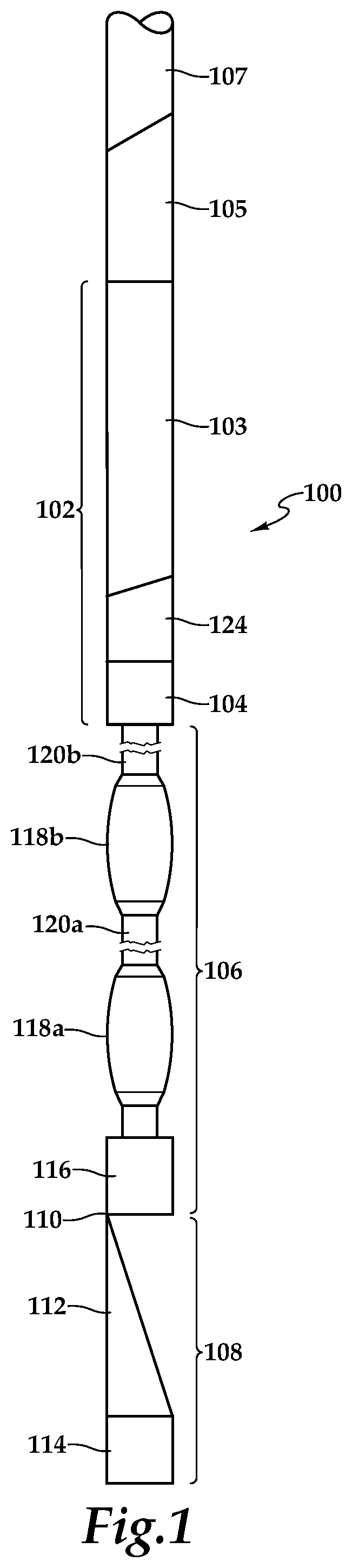

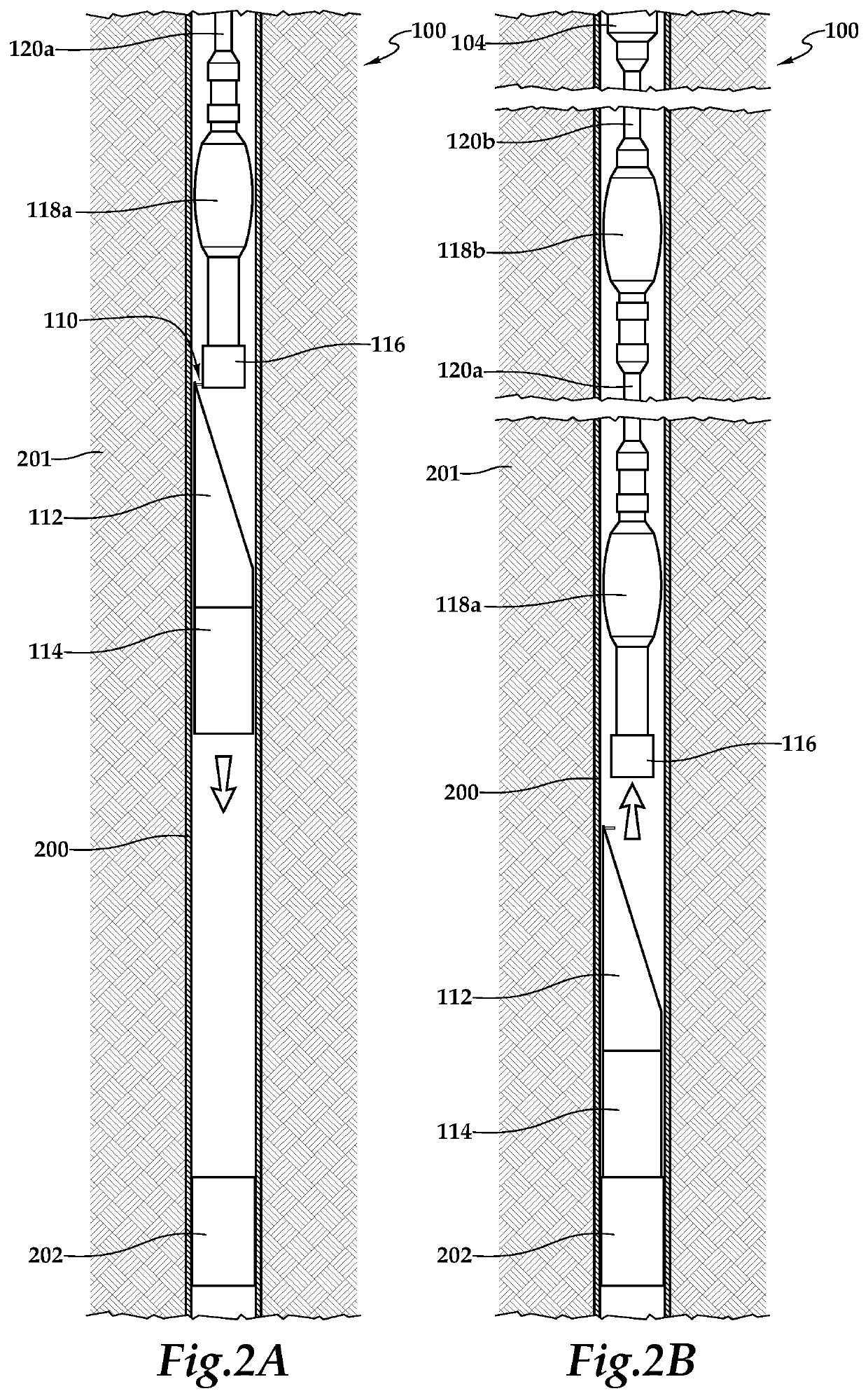

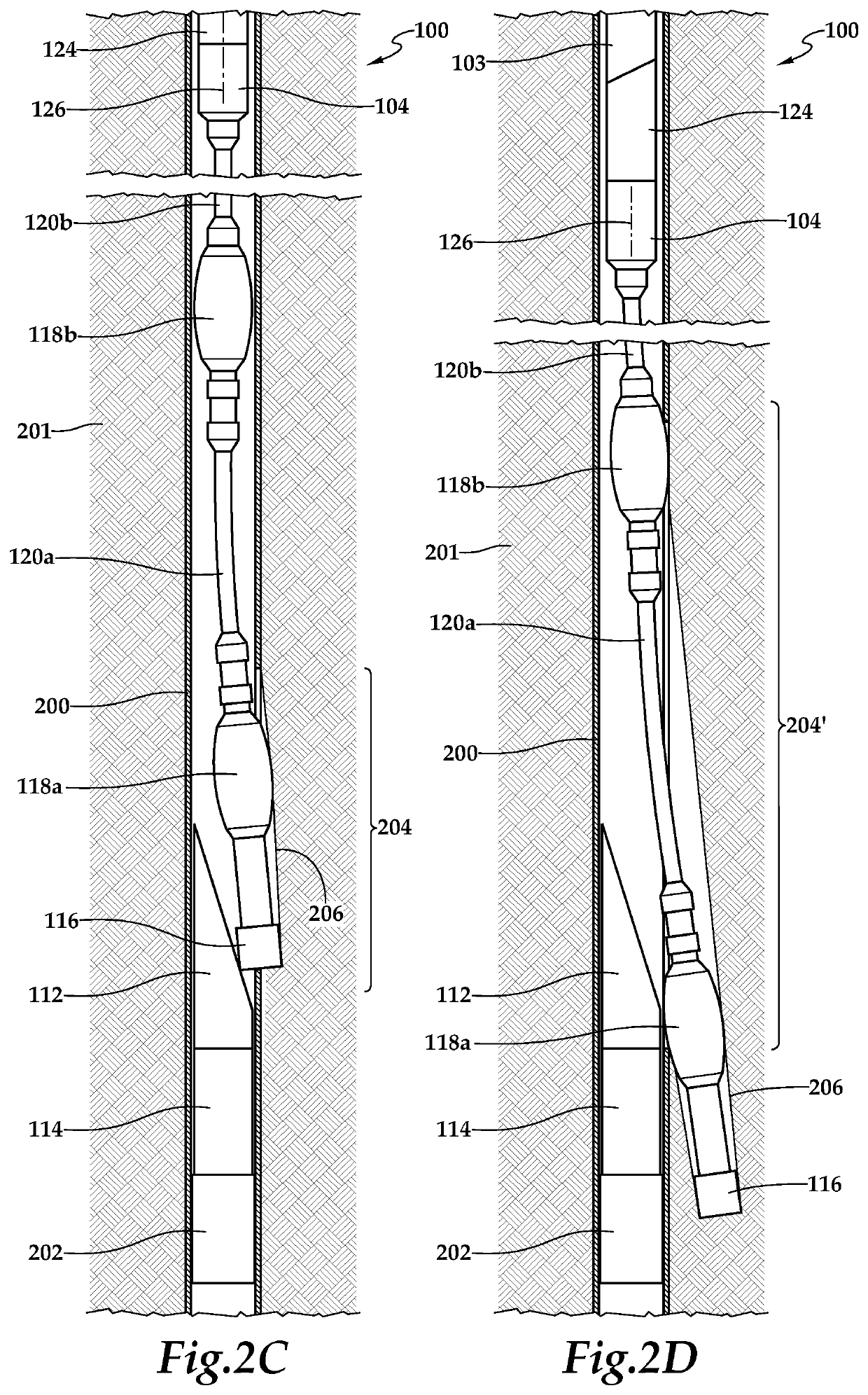

[0019]The following description discloses representative, non-limiting embodiments of a downhole tool capable of operating in a milling mode to cut a window in wellbore casing and then changing to a directional drilling mode in which the face of the tool rotates off-axis to allow the tool to be steered.

[0020]The tool is configured so that, in the milling mode, it is capable of, orienting and setting a whipstock, cutting a window in the wellbore's casing, and creating a rat hole, after which it can be changed to a directional drilling mode by adjusting the tool from having no bend to having a bend that changes the orientation of the tool face from zero degrees, which is oriented along the axis of the drill string, to a non-zero degree angle without having to remove the BHA from the wellbore.

[0021]In the simplified, representative embodiment sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com