Method and apparatus for detecting combustion knock from the ionic current in an internal combustion engine

a technology of ionic current and internal combustion engine, which is applied in the direction of mechanical equipment, machines/engines, instruments, etc., can solve the problems of uncontrollable explosion of the as-yet unburned fuel-air mixture, unfavorable auto-ignition and uncontrolled explosion, vibration of engine components, etc., and achieves the effect of reducing the risk of engine failure, and reducing the efficiency of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

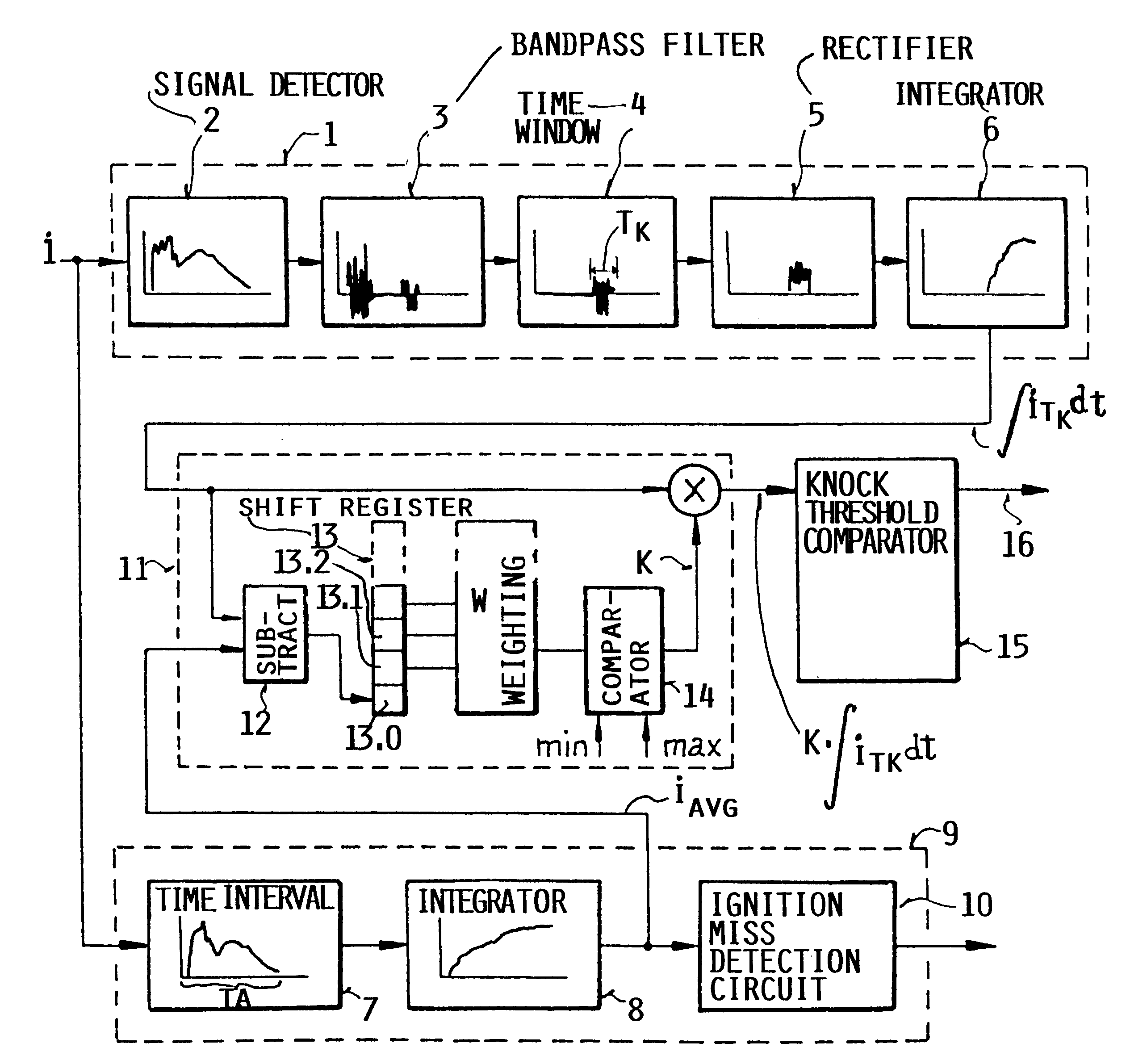

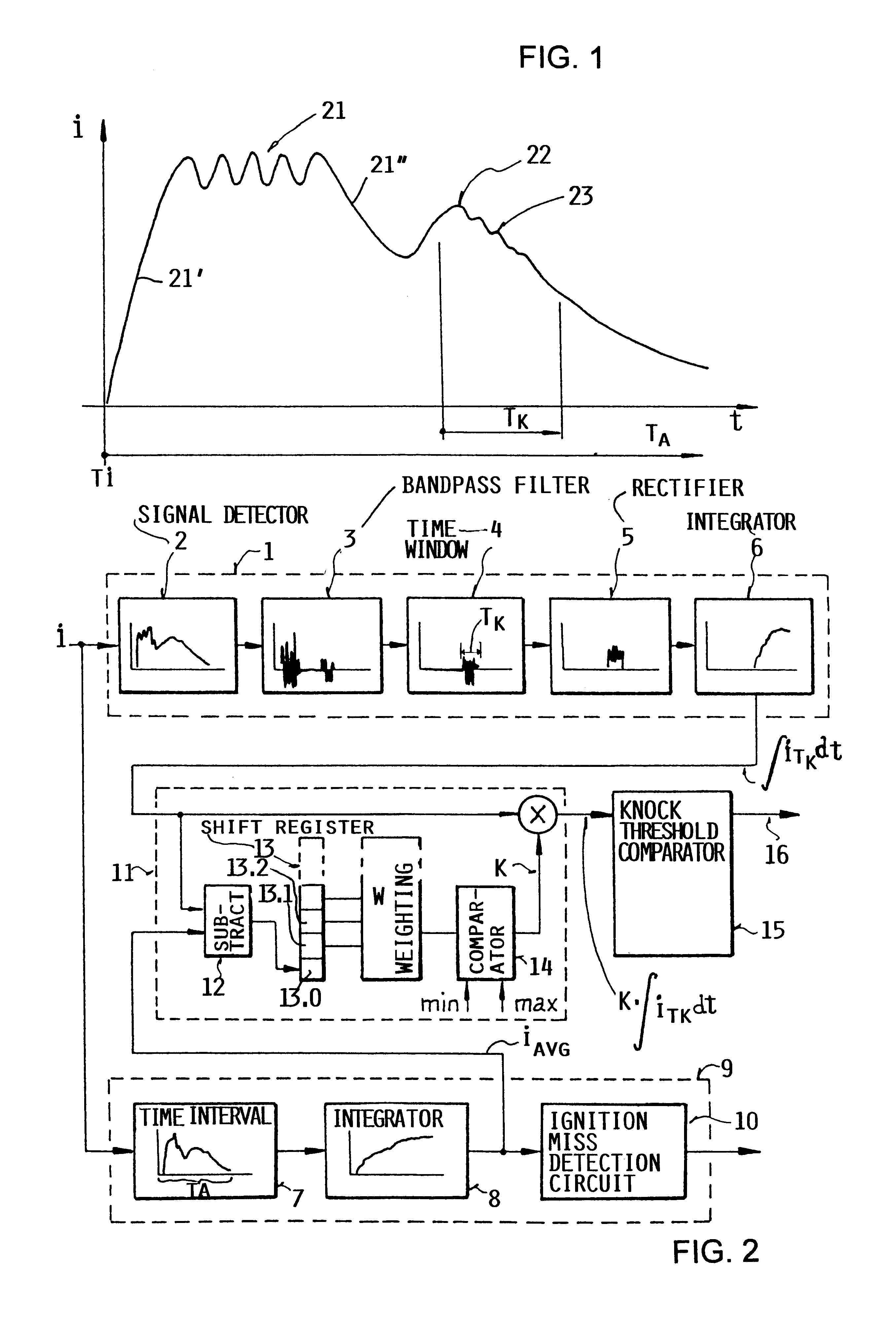

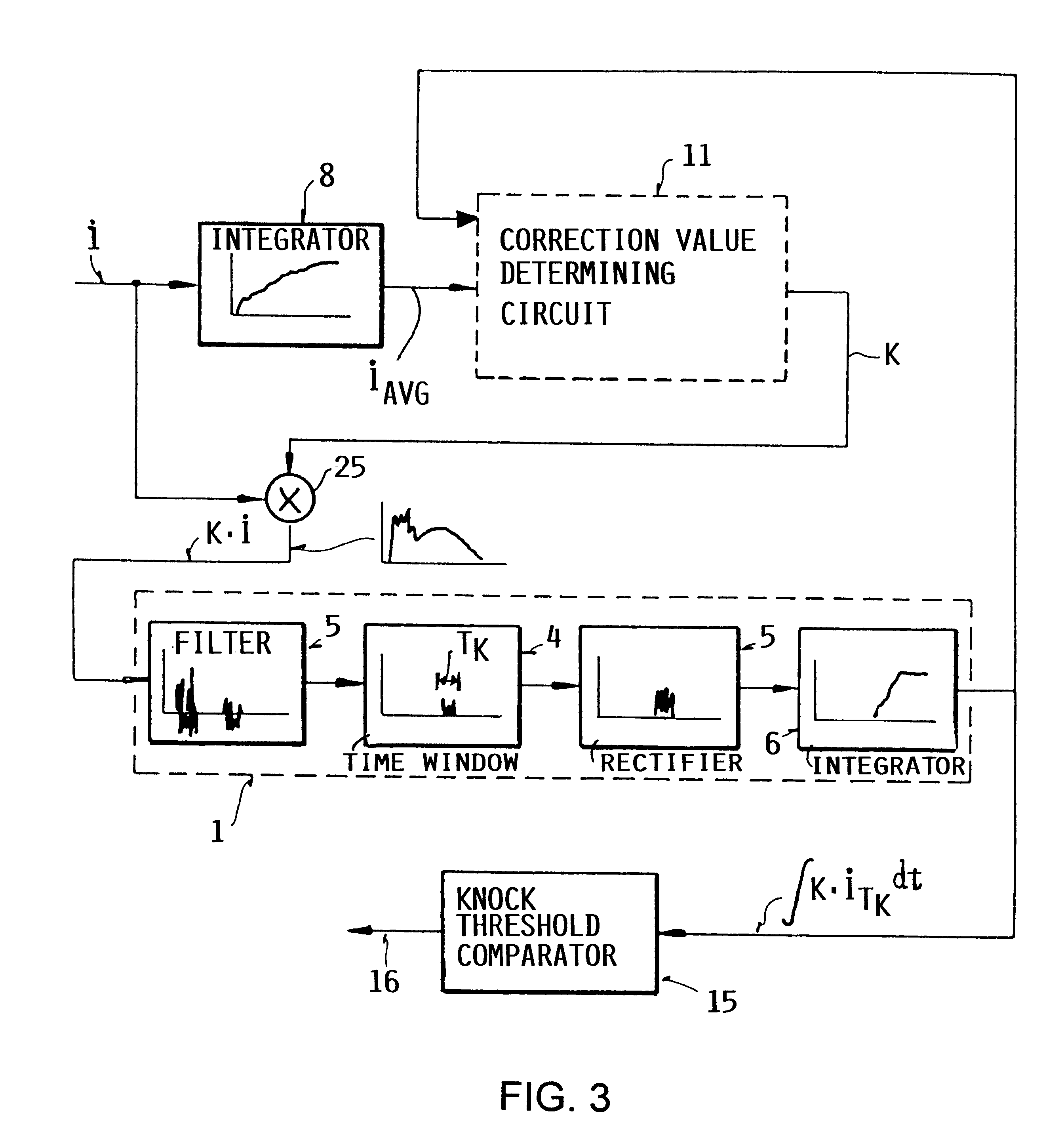

FIG. 1 shows the time progress of the ionic current signal i during a single combustion cycle in a cylinder of an internal combustion engine. It should be understood that the present method and apparatus can be respectively used in connection with any one or more of the cylinders in an engine. After the time of ignition Ti, the flame front expands through the combustion chamber and causes a sharp increase 21' in the ionic current signal i up to the primary signal maximum 21. The signal level at the primary maximum 21 may exhibit oscillations due to turbulence and the like as the flame front progresses through the combustion chamber.

Thereafter, the signal level of the ionic current signal i drops off slightly at 21", and then the signal level again increases up to a secondary local maximum 22 at the point of maximum pressure or compression during the combustion cycle. In the case of combustion without knocking, the amplitude or signal level of the ionic current signal i will smoothly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| ionic current | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com