Apparatus for removing contaminants from crankcase emissions

a technology of crankcase and filter, which is applied in the direction of machine/engine, liquid degasification, separation process, etc., can solve the problems of a large amount of liquid in the fluid stream, and achieve the effects of reducing unwanted engine deposits, improving engine performance, and increasing engine li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

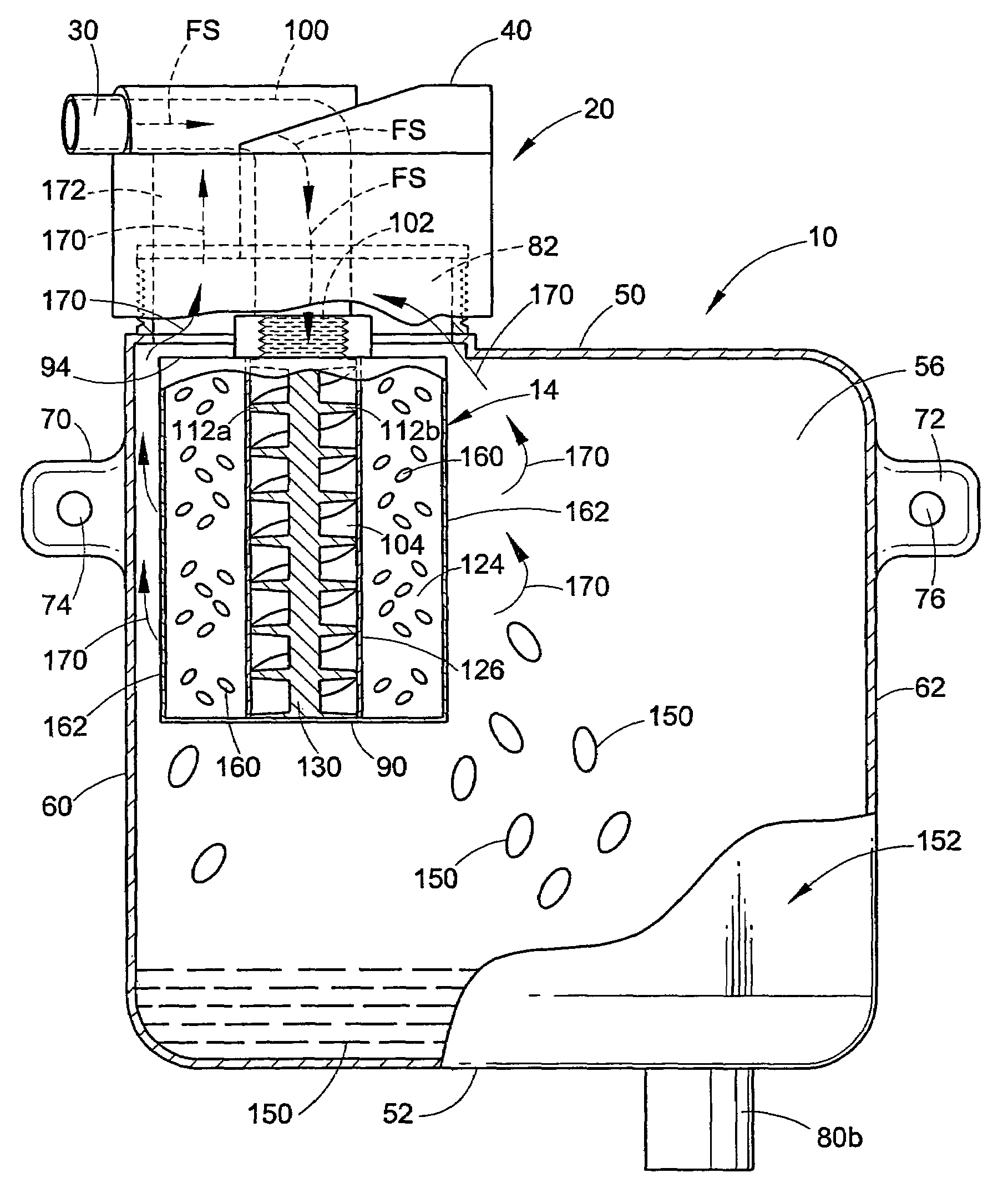

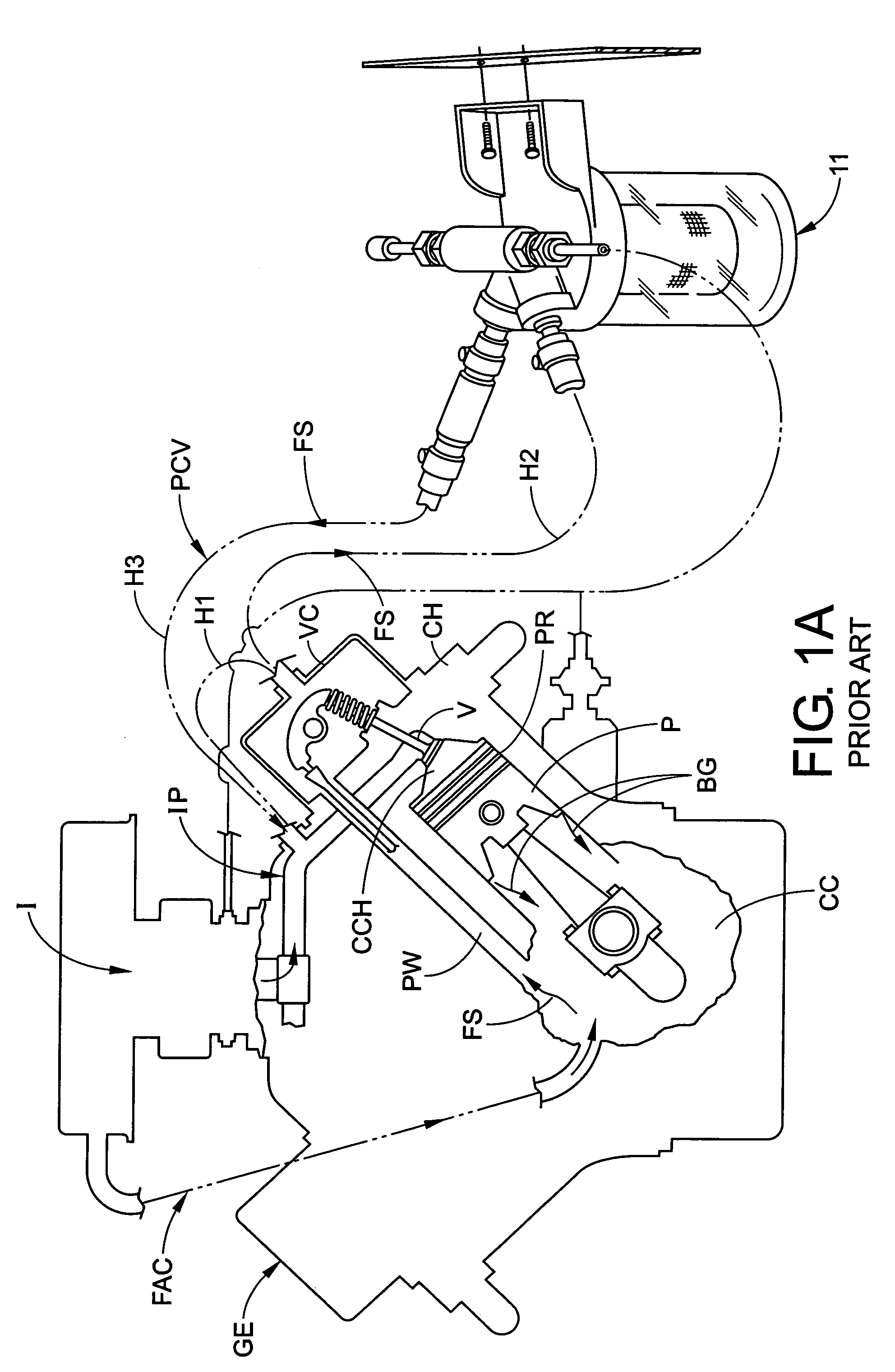

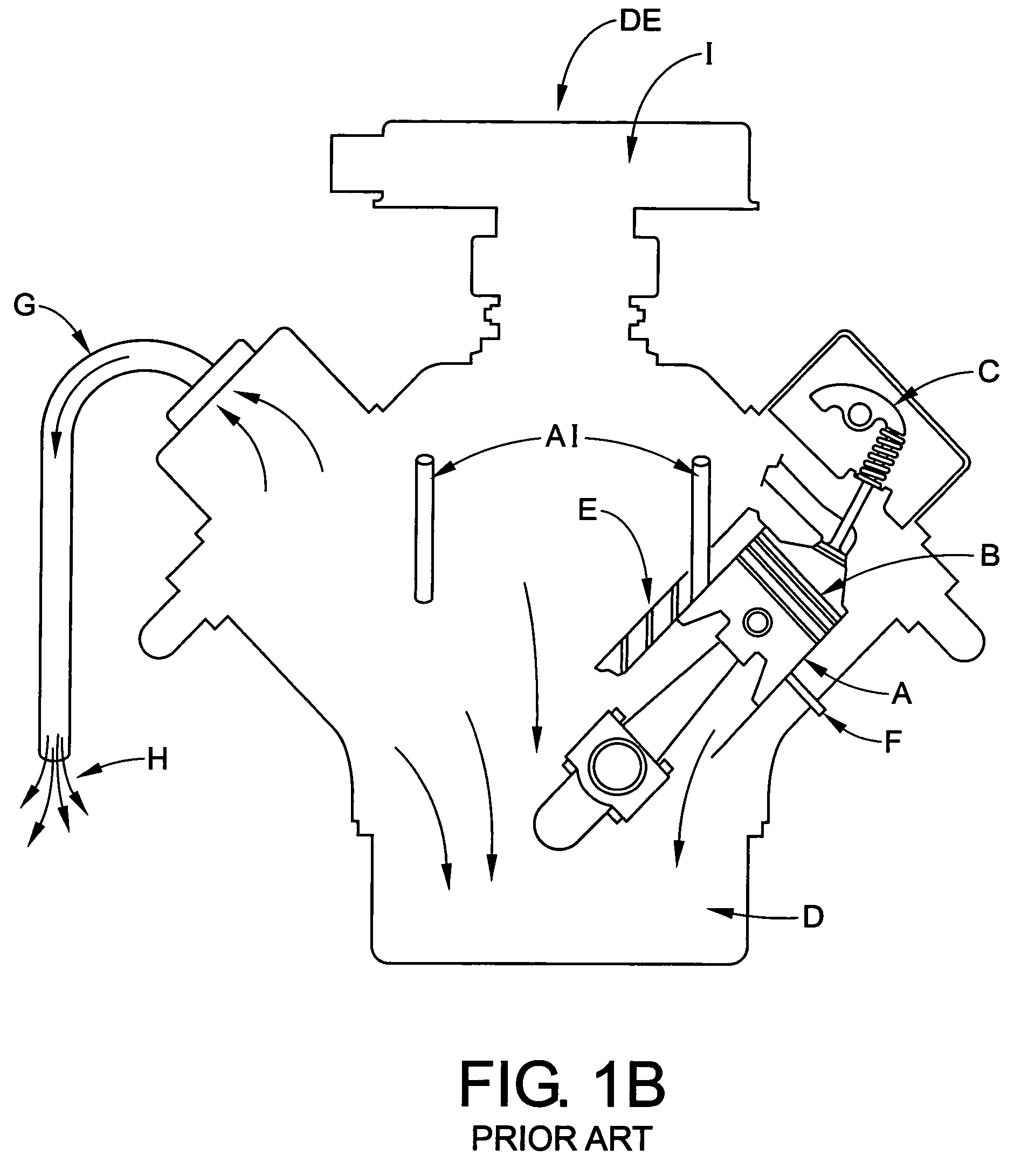

[0030]Referring now in greater detail to the drawings wherein the showings are for the purpose of illustrating preferred embodiments of the invention only, and not for the purpose of limiting the invention, FIG. 1A illustrates a PCV system for a gasolene engine along with a prior art separator used in connection with the PCV system. More particularly, shown is a gasolene type internal combustion engine GE having a crankcase CC, an intake I and at least one cylinder head CH. In operation, intake I delivers a mixture of fuel and air through intake passageway IP into cylinder head CH which is directed to combustion chamber CCH. A valve V regulates the flow of the fuel-air mixture to the combustion chamber. Piston P then compresses the fuel-air mixture wherein during the compression process, a small portion, depending on the condition of the engine, passes by piston P as “blow-by” gasses BG into crankcase CC. In similar fashion, during the combustion of the fuel-air mixture, a portion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com