Anti-rotation device and anti-rotation structure for a pipe and a connector

a technology of anti-rotation device and anti-rotation structure, which is applied in the direction of hose connection, pipe coupling, coupling, etc., can solve the problems of limited piping design freedom, deterioration of sealing property between the connector and the pipe, and worn pipes, so as to achieve easy verification or finding, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

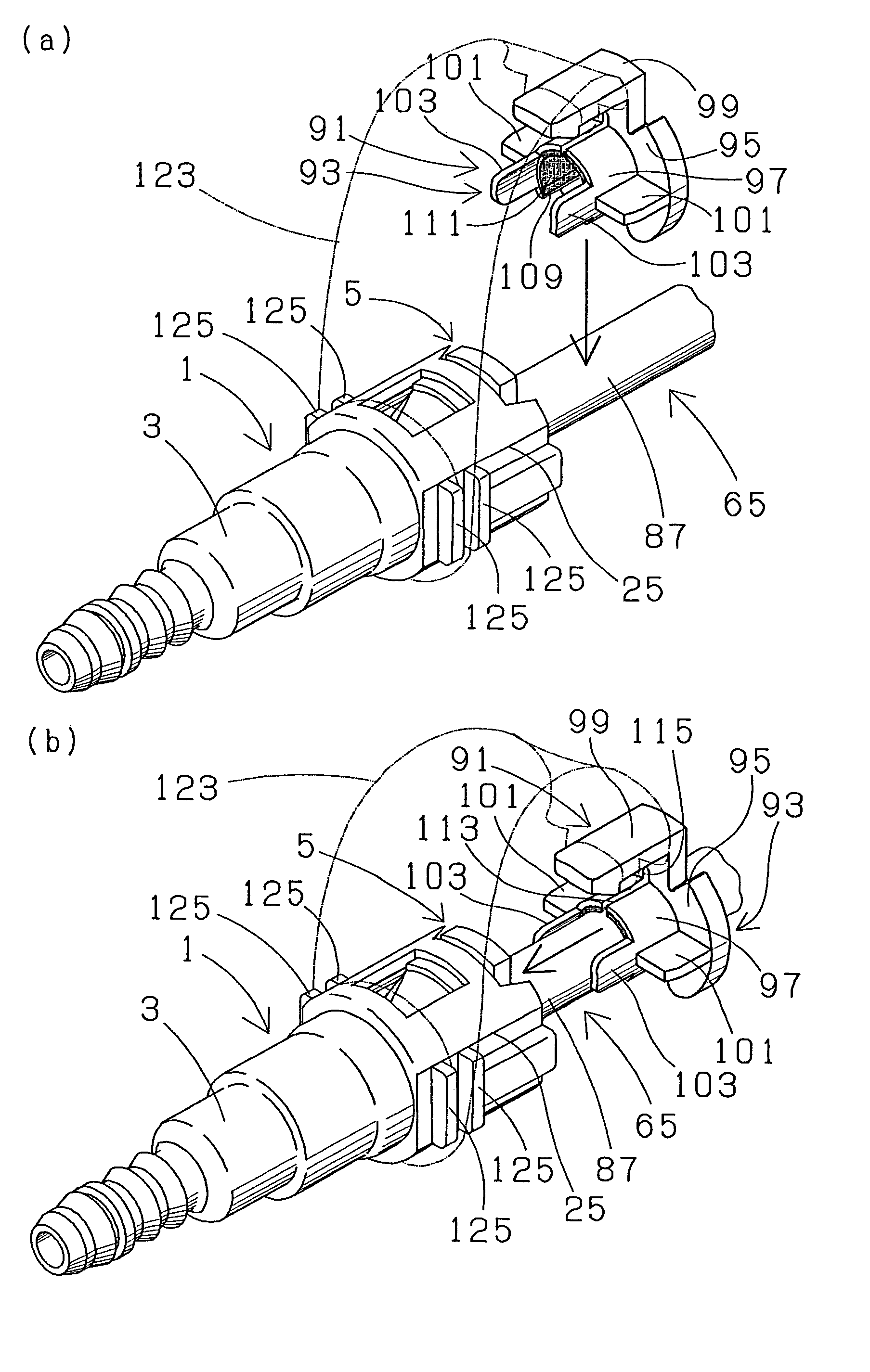

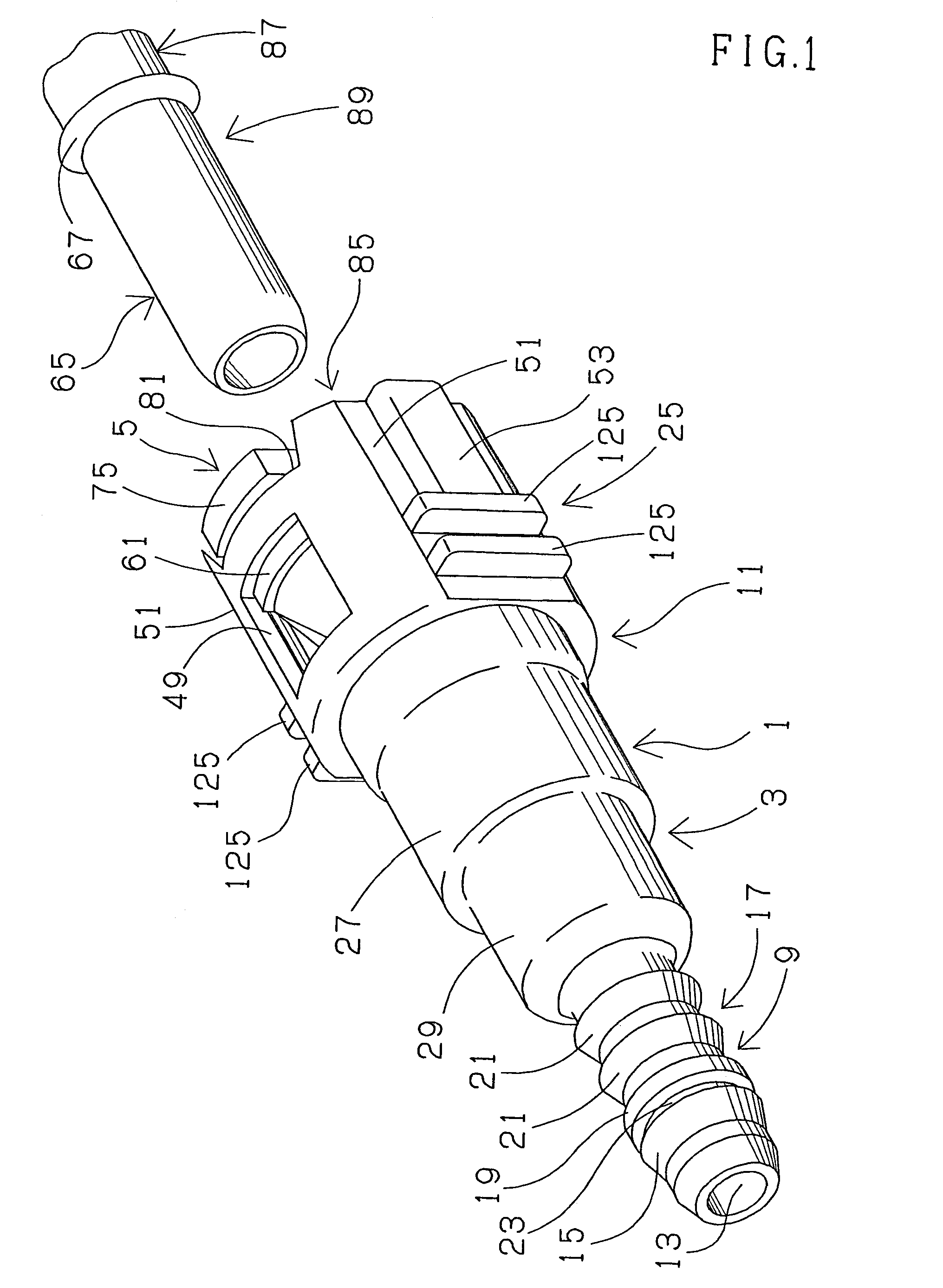

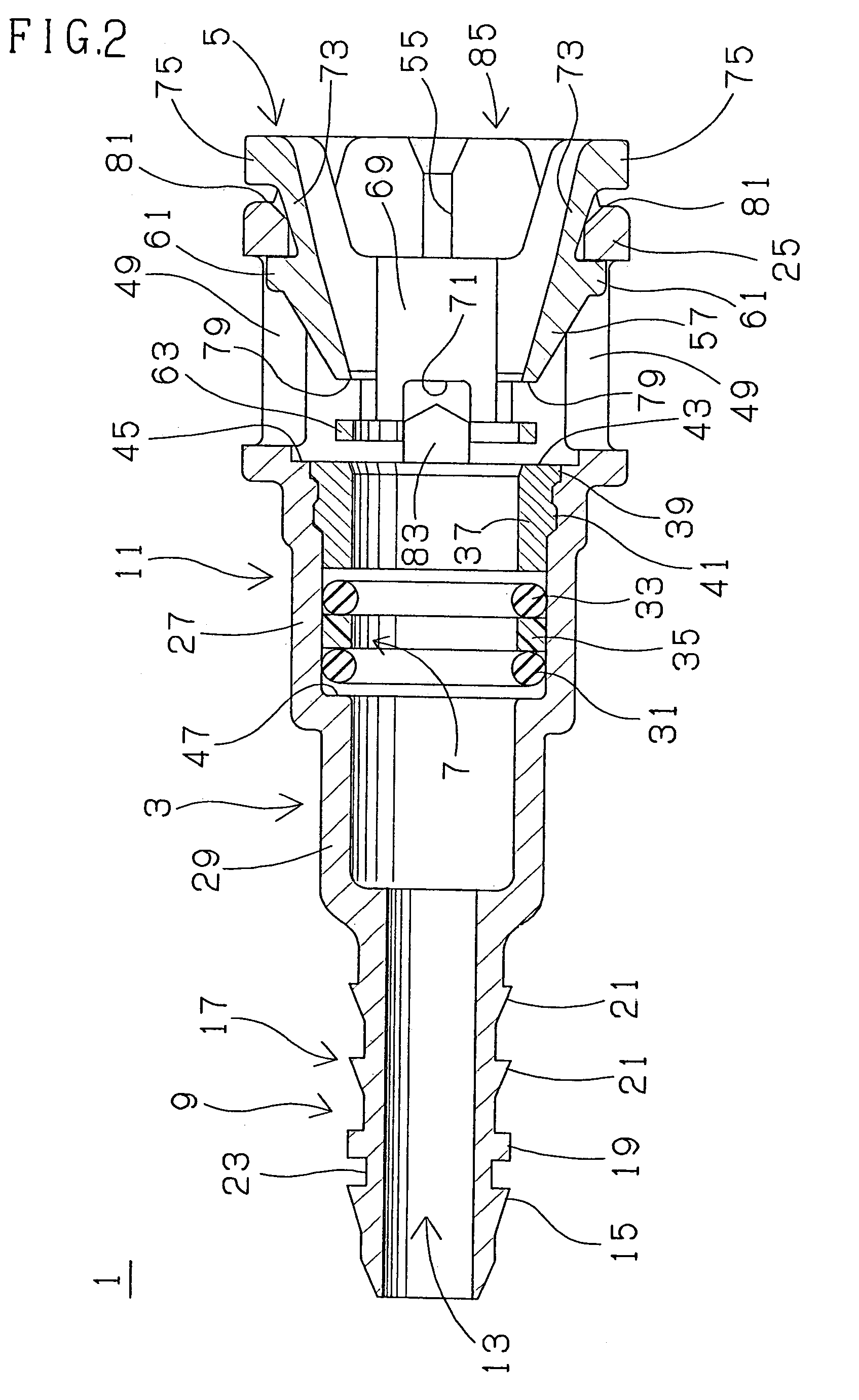

[0082]A first anti-rotation structure for a pipe and a connector is explained with reference to FIGS. 1 to 13. A first quick connector 1, which is adapted for assembly in a gasoline fuel piping of an automobile and adapted in the first anti-rotation structure comprises a tubular connector housing 3, a generally annular retainer 5 and sealing means 7 as well shown in FIGS. 1 and 2. The connector housing 3 made of glass fiber reinforced polyamide (PA•GF), integrally comprises a cylindrical resin tube connecting portion 9 on one axial end of the connector housing and a generally cylindrical pipe inserting portion 11 on the other axial end of the connector housing, and is provided with a through-bore 13 through from one axial end to an opposite axial end thereof. The resin tube connecting portion 9 comprises one axial side portion 15 having an outer peripheral surface generally expanding gently in diameter toward the other axial end, and an opposite axial side portion 17 having an outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com