Vision inspection apparatus using a full reflection mirror

a technology of reflection mirrors and inspection apparatuses, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of large installation space, serious vibration, and each component accompanies large loads, and achieve the effect of improving the effect of inspection operation efficiency and driving torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Hereinafter, the detailed description of a preferred embodiment of the present invention will be apparent in connection with the accompanying drawings.

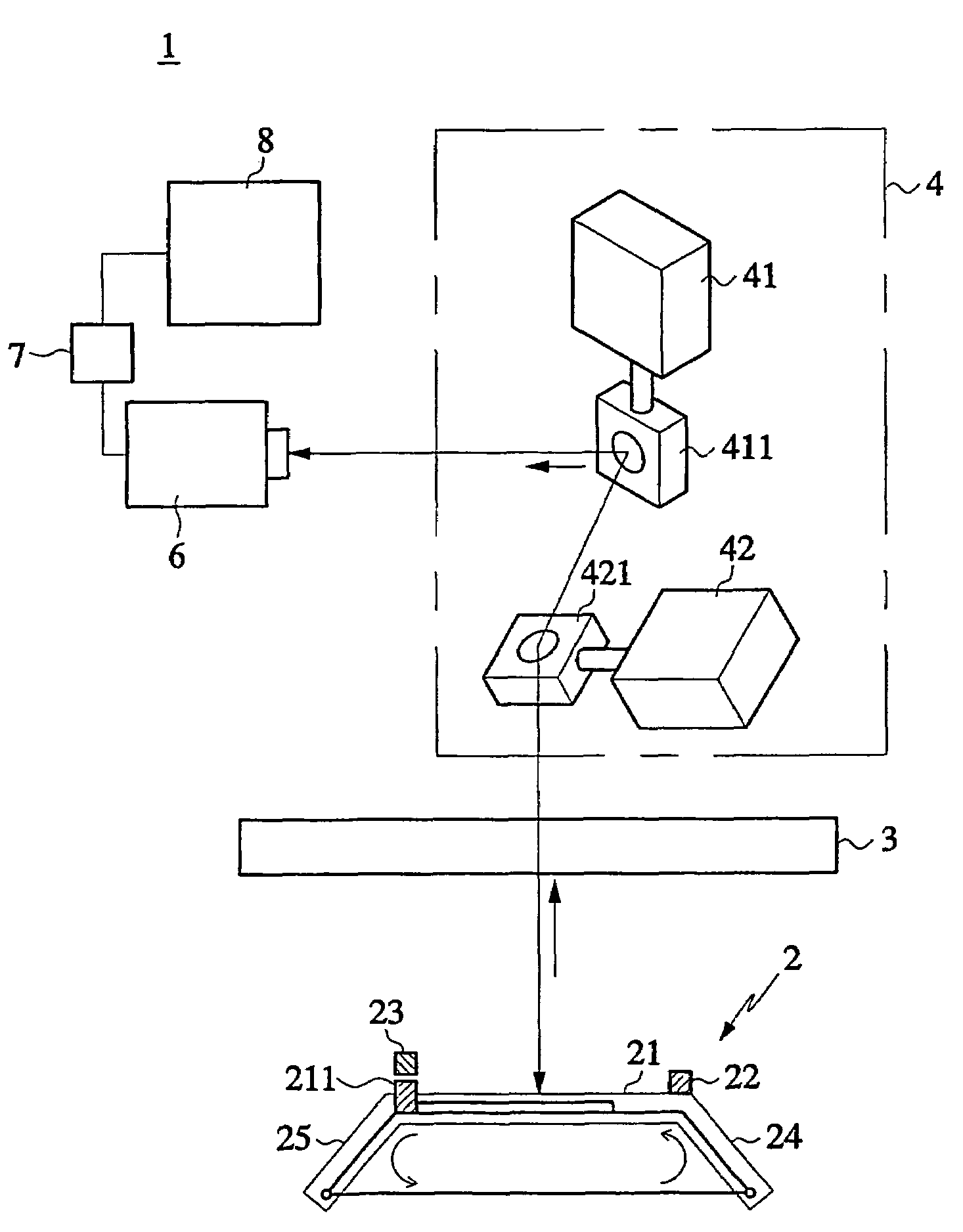

[0030]Referring to FIG. 3A, a vision inspection apparatus 1 in accordance with the present invention is installed so that a printed circuit board that a surface mounting operation is completed in a surface mounting assembly line can accomplish a vision inspection prior to a movement to the next process through a conveyor of a preceding apparatus. As a preferred embodiment, the vision inspection apparatus is installed between a surface mounting machine provided with a conveyor and a re-flow machine or between a high-speed mounting machine and a heteromorphy-mounting machine in the surface mounting assembly line. The vision inspection apparatus in the prior art surface mounting assembly line does not need to change its location as the vision inspection apparatus is located at a dead-space formed between conveyors of the preceding / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| incidence angle | aaaaa | aaaaa |

| reflection angle | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com