Ozone exhaust system for image forming apparatus

a technology of image forming apparatus and exhaust system, which is applied in the direction of oxygen/ozone/oxide/hydroxide, electrographic process, instruments, etc., can solve the problems of printing defects, damage to the photoconductive layer of the photoreceptor used in the image forming apparatus, and harmful effects on human body and environment, so as to reduce the residual ozone concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The best mode for carrying out the present invention will hereinafter be described with reference to the drawings.

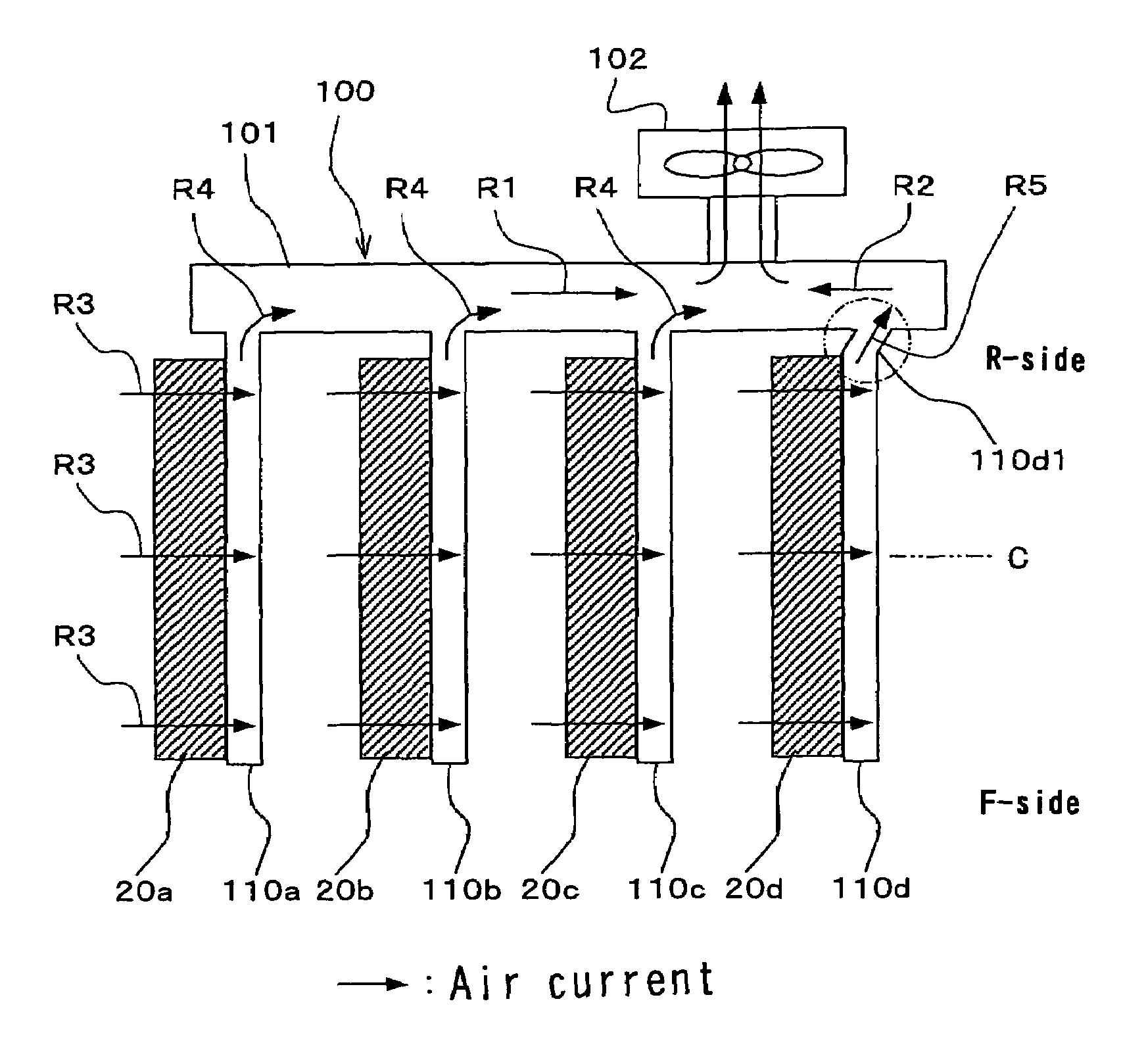

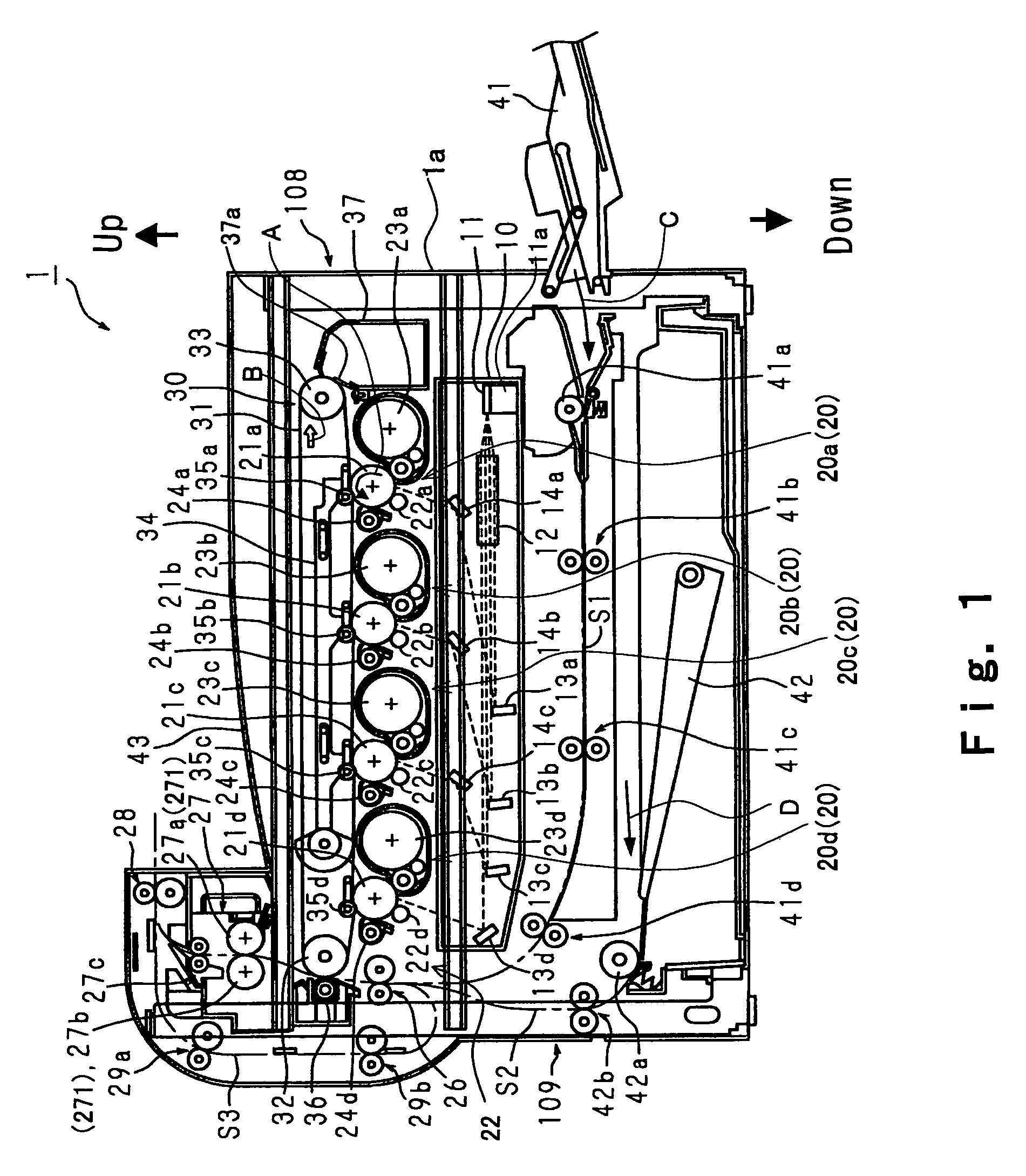

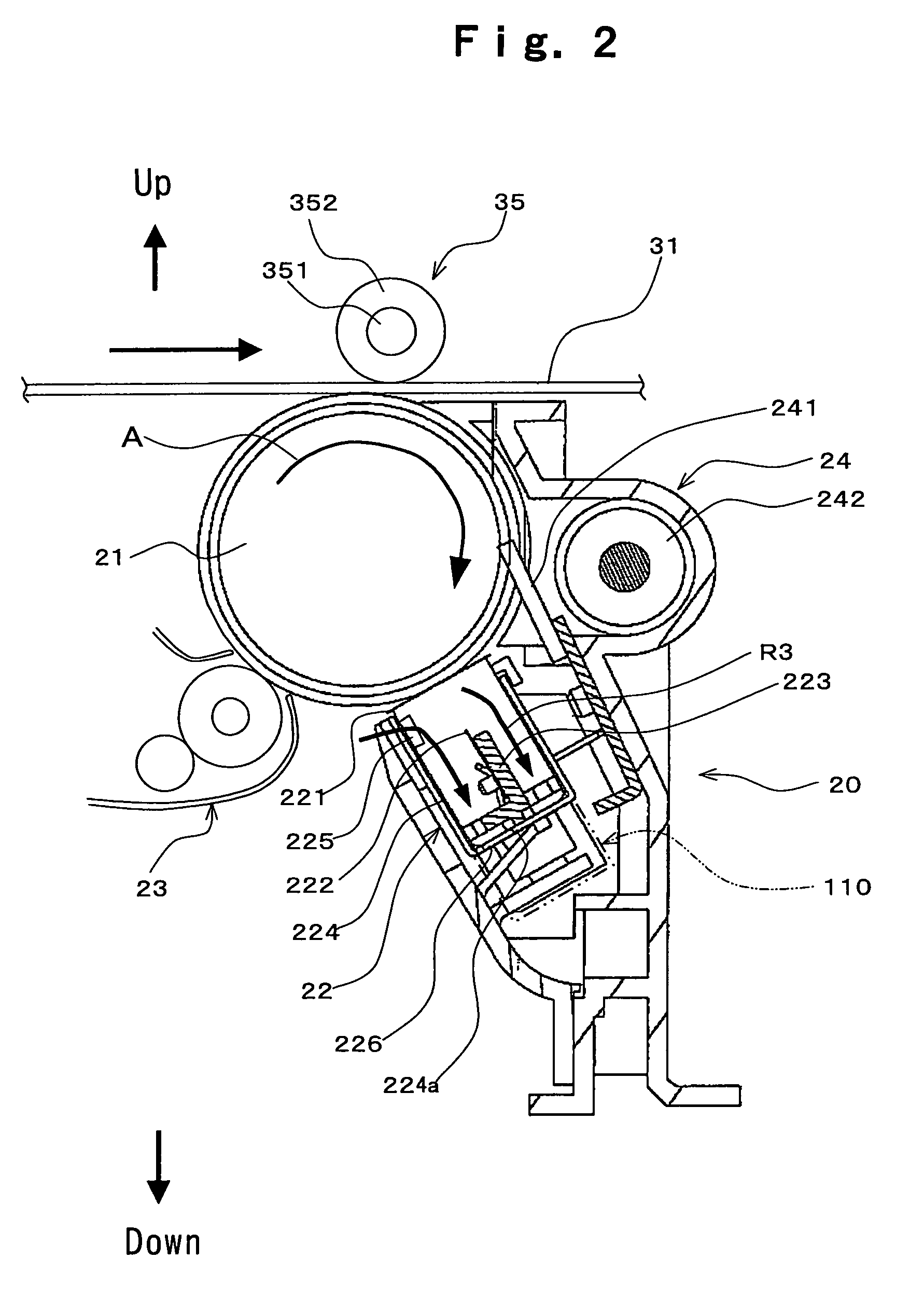

[0048]FIGS. 1 to 3 show one embodiment mode of the present invention, and FIG. 1 is an illustrative diagram (sectional view from the rear) showing the overall configuration of an image forming apparatus according to the embodiment mode of the present invention; FIG. 2 is an illustrative diagram showing the configuration of a process printing unit as a constituent of the image forming apparatus; and FIG. 3 is an illustrative diagram showing the arrangement of chargers as the constituents of the process printing units and exhaust ducts connected to the chargers.

[0049]As shown in FIGS. 1 and 2, an image forming apparatus 1 of the present embodiment mode includes: a plurality of process printing units 20 (20a, 20b, 20c and 20d) each creating a separated color image corresponding to a color of color-separated image information; and an ozone exhaust system having exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com