Optical pickup device and optical disk device

a pickup device and optical disk technology, applied in the direction of mountings, instruments, data recording, etc., can solve the problems of increasing the amount of spherical aberration caused by varying wavelengths, oscillation wavelength, and increasing so as to reduce the amount of spherical aberration, increase the yield of light sources, and extend the tolerance range of differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 6

[0333]In the objective lens of Example 6, the reference characters f, n, d, and NA are as below.

[0334]f: 1.41 [mm]

[0335]n: 1.525

[0336]d: 1.93 [mm]

[0337]NA: 0.85

[0338]The reference characters R, K, and Ai representing the shape of the first surface on the light-entering side of the objective lens of Example 6 are as below. The nth-order coefficient Cn of an optical-path difference determining the length of increase φ (h) of the optical path by the zone diffractive structure provided to the first surface is as below.

[0339]Shape of First Surface

[0340]R: 0.921 [mm]

[0341]K: −0.662

[0342]A4: 1.108×10−2

[0343]A6: 2.098×10−2

[0344]A8: −2.414×10−2

[0345]A10: 1.585×10−2

[0346]A12: −4.195×10−3

[0347]A14: −3.362×10−3

[0348]A16: −3.060×10−3

[0349]A18: 8.197×10−3

[0350]A20: −3.879×10−3

[0351]C2: 17.55

[0352]C4: −30.03

[0353]C6: 21.63

[0354]C8: −28.00

[0355]C10: 5.79

[0356]The reference characters R, K, and Ai representing the shape of the second surface on the light-exiting side of the objective lens o...

example 1

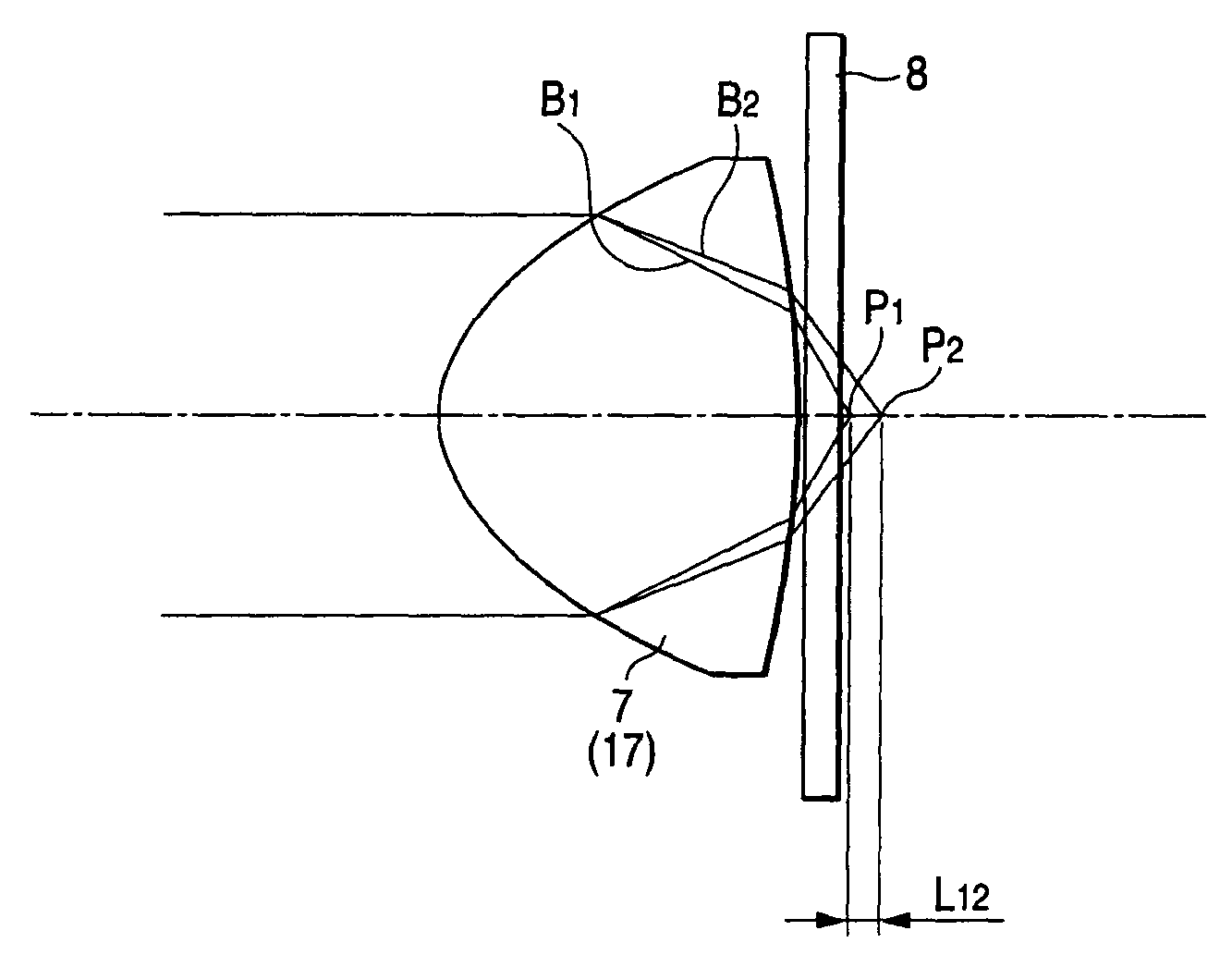

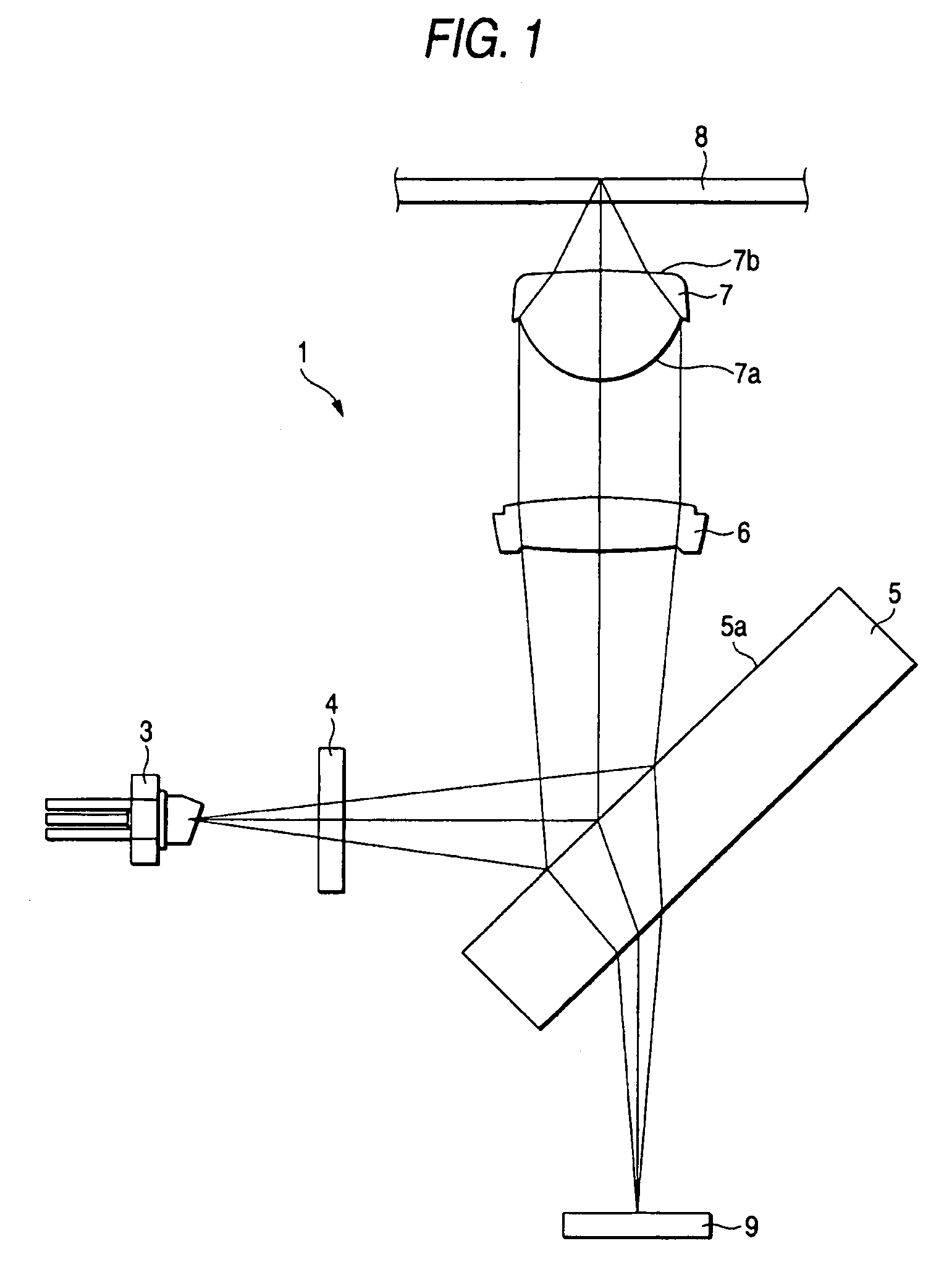

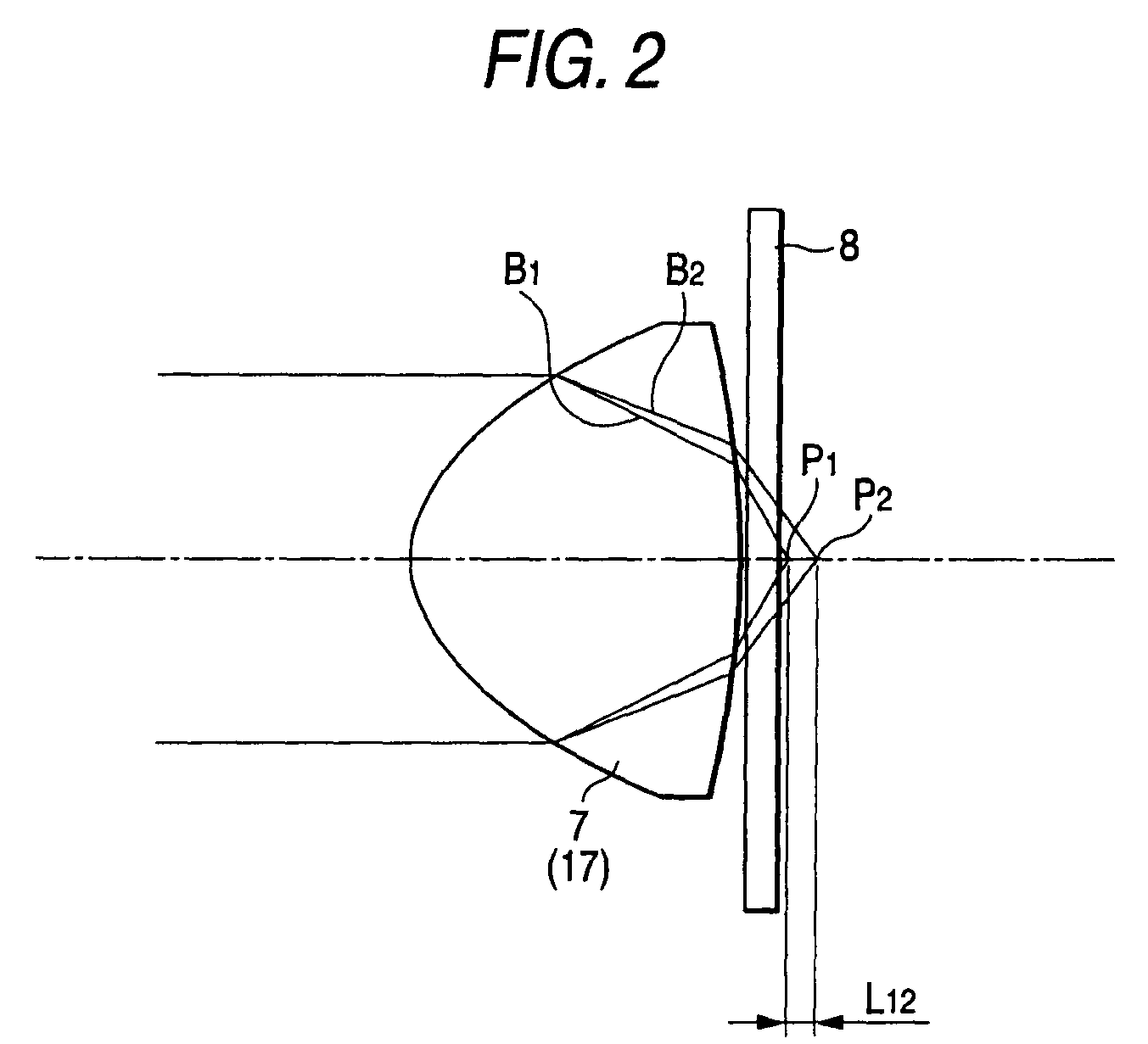

[0426]In the objective lens of Example 1, the reference characters are as described above, i.e., f, n, d, and NA, R, K, and Ai indicating the shape of the first surface on the light-entering side, Cn indicating the nth-order coefficient of an optical path difference determining the length increase φ (h) for the optical path of the diffractive configuration provided to the first surface, and R, K, and Ai indicating the shape of the second surface on the light-exiting side.

[0427]In such an objective lens of Example 1, as a result of some wavelength change, any change observed between SA3 being the third-order spherical aberration and SA5 being the fifth-order spherical aberration is derived as shown in FIG. 6. In such an objective lens of the first example, the third-order spherical aberration on the axis is −0.2 mλrms, and the fifth-order spherical aberration is 0.4 mλrms, which are both suppressed to be sufficiently small.

[0428]The change of third-order spherical aberration with res...

example 2

[0433]In the objective lens of Example 2, the reference characters are as described above, i.e., f, n, d, and NA, R, K, and Ai indicating the shape of the first surface on the light-entering side, Cn indicating the nth-order coefficient of an optical path difference determining the length increase φ (h) for the optical path of the diffractive configuration provided to the first surface, and R, K, and Ai indicating the shape of the second surface on the light-exiting side.

[0434]In such an objective lens of Example 2, as a result of some wavelength change, any change observed between SA3 being the third-order spherical aberration and SA5 being the fifth-order spherical aberration is derived as shown in FIG. 7. In such an objective lens of Example 2, the third-order spherical aberration on the axis is −0.4 mλrms, and the fifth-order spherical aberration is 0.1 mλrms, which are both suppressed to be sufficiently small.

[0435]The change of third-order spherical aberration with respect to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com