System and method for producing hot water without a flame

a technology of system and method, which is applied in the field of system and method apparatus for producing hot water without flame, can solve the problems of ongoing maintenance requirement of filter replacement, untold number of human deaths every year, and the filter in the ro system can become clogged and/or damaged, so as to eliminate or reduce at least some of the disadvantages and problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

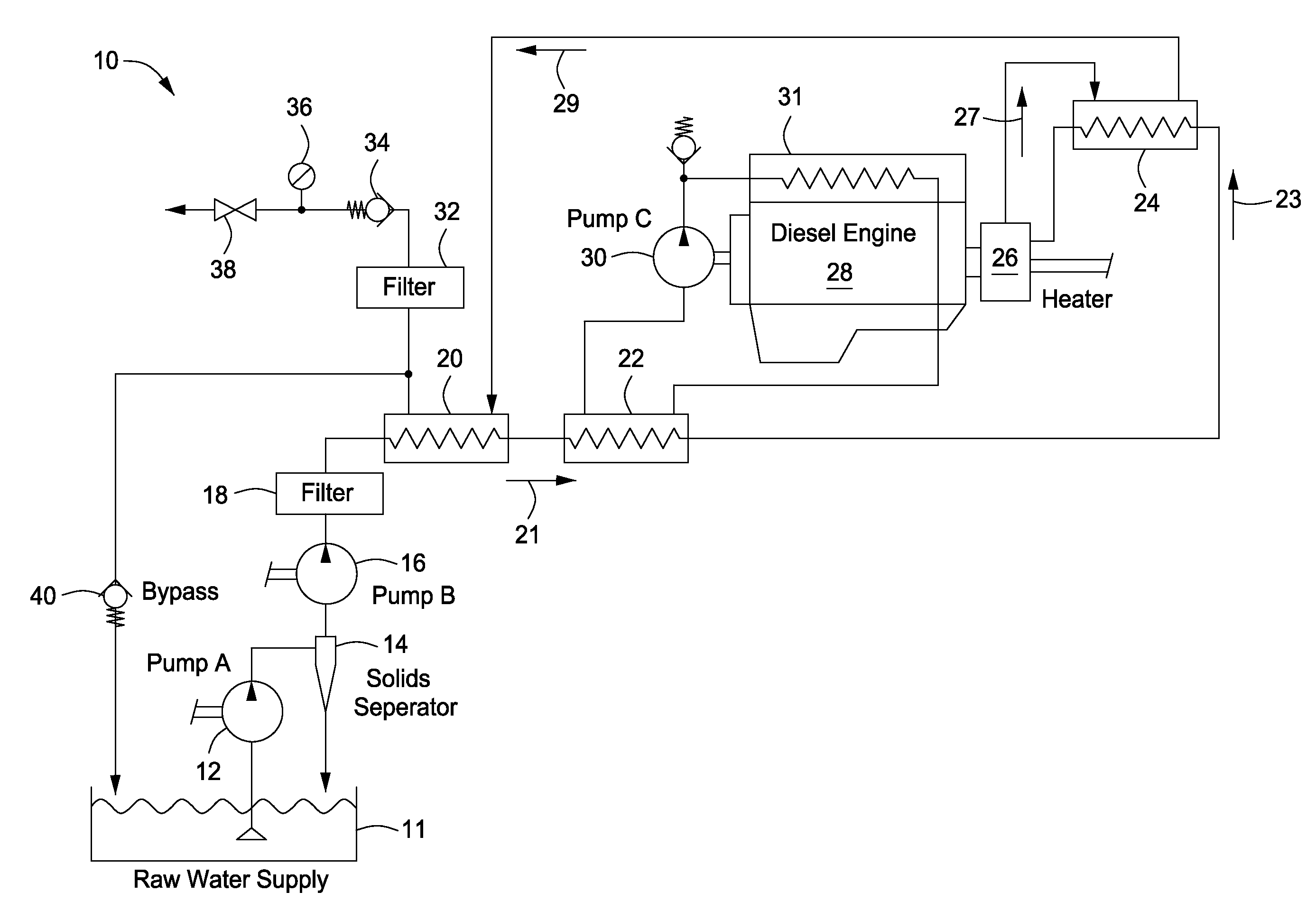

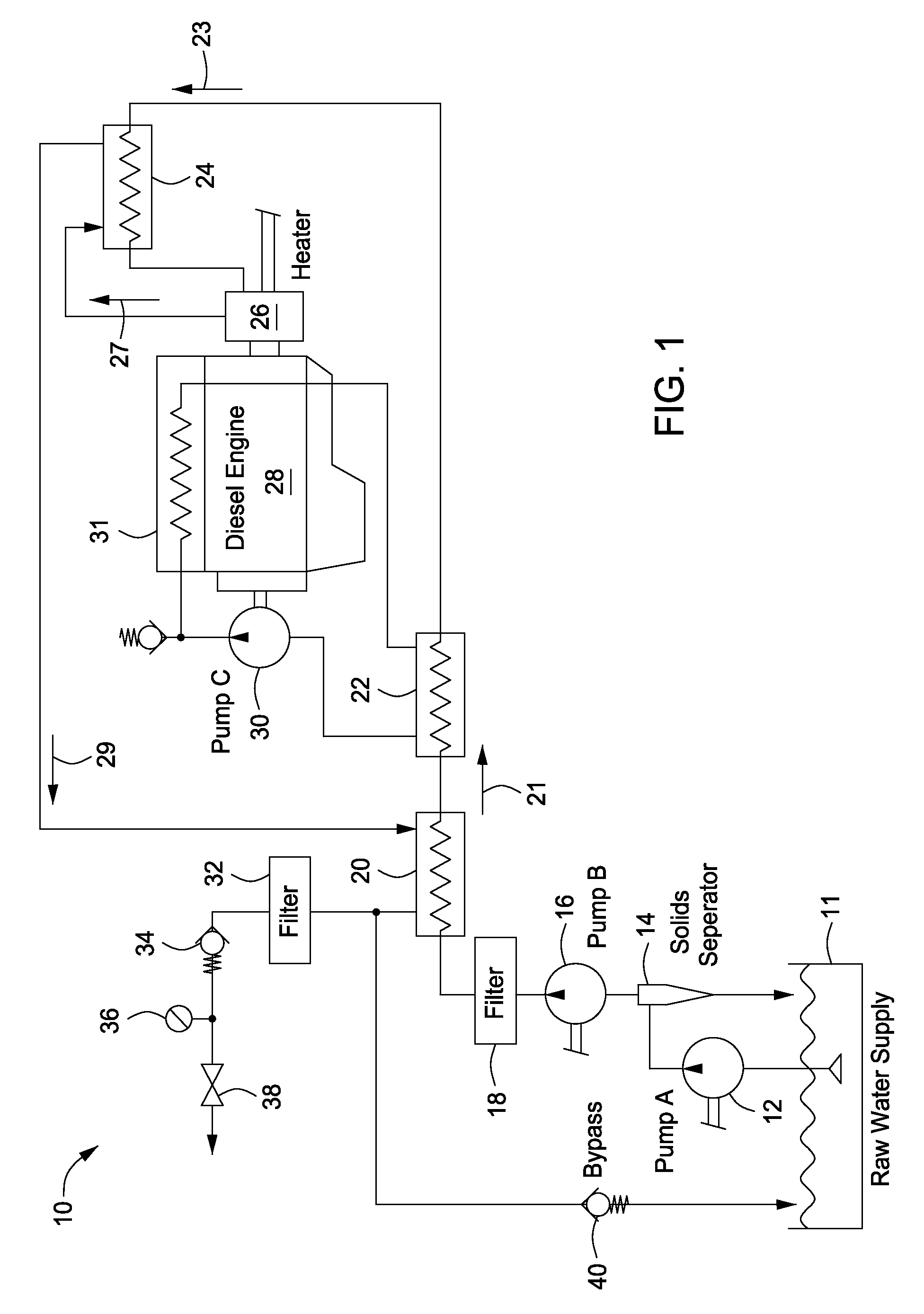

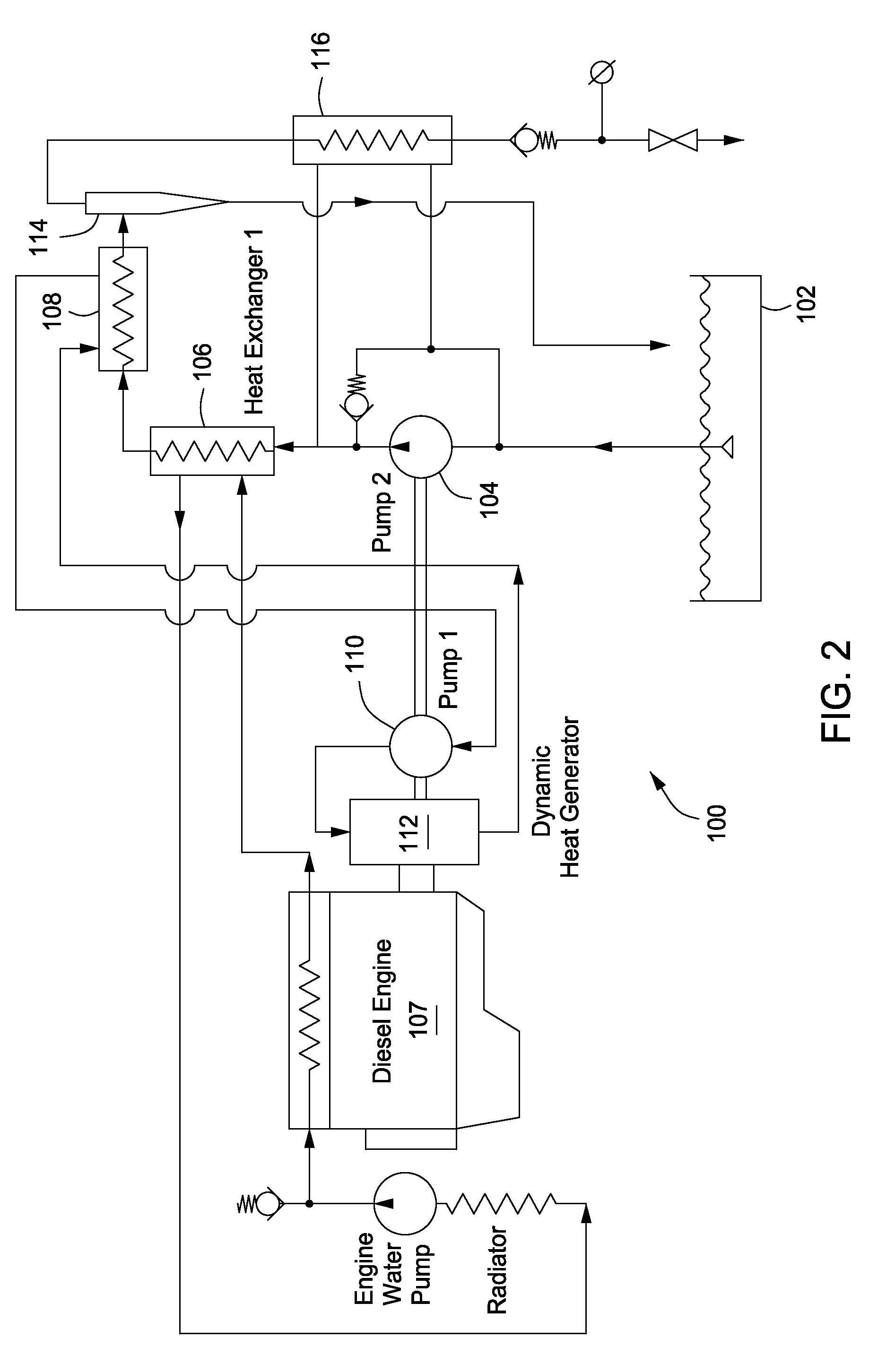

[0024]While the making and using of various embodiments of the present invention are discussed in detail below, it should be appreciated that the present invention provides many applicable inventive concepts that can be embodied in a wide variety of specific contexts. The specific embodiments discussed herein are merely illustrative of specific ways to make and use the invention and do not delimit the scope of the invention. The discussion herein relates primarily to heating water, but it will be understood that the concepts of the present invention are applicable to any system and method for heating liquids without using open flames for killing pathogens in water, distilling water, producing radiant heat, melting paraffin in oil wells, and steam reforming of petroleum fuels for the production of hydrogen for use in fuel cells.

[0025]The ability to heat water above 212 degrees Fahrenheit, to kill pathogens without the need of an open flame, makes this system adaptable to all types of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com