Supervisory control and data acquisition protocol converter

a supervising control and data acquisition technology, applied in the field of electronic protocol converters, can solve the problems of inability to reverse engineer, inability to achieve standardized data acquisition between various manufactures, and inability to achieve standardized data acquisition between different manufactures,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

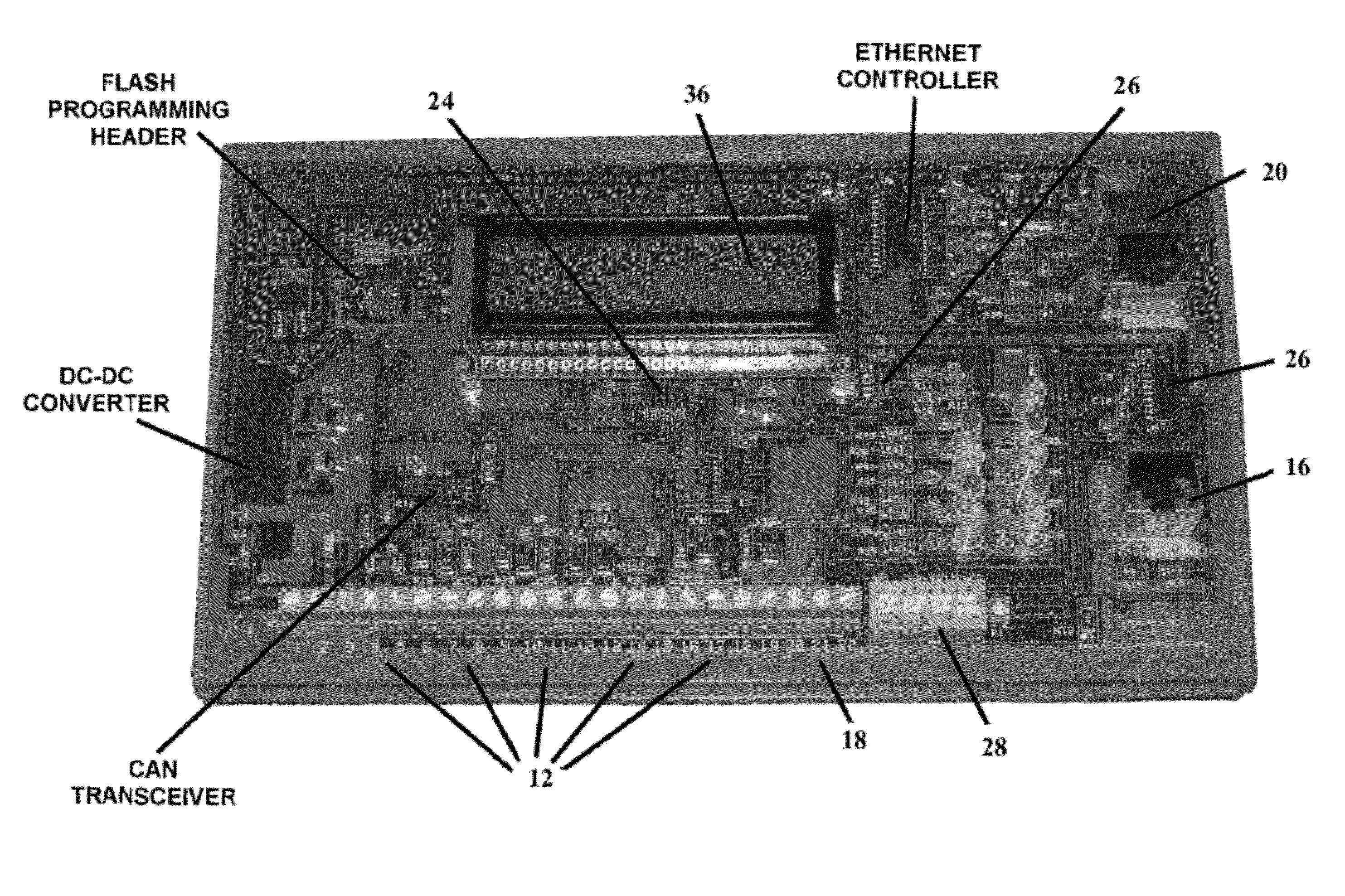

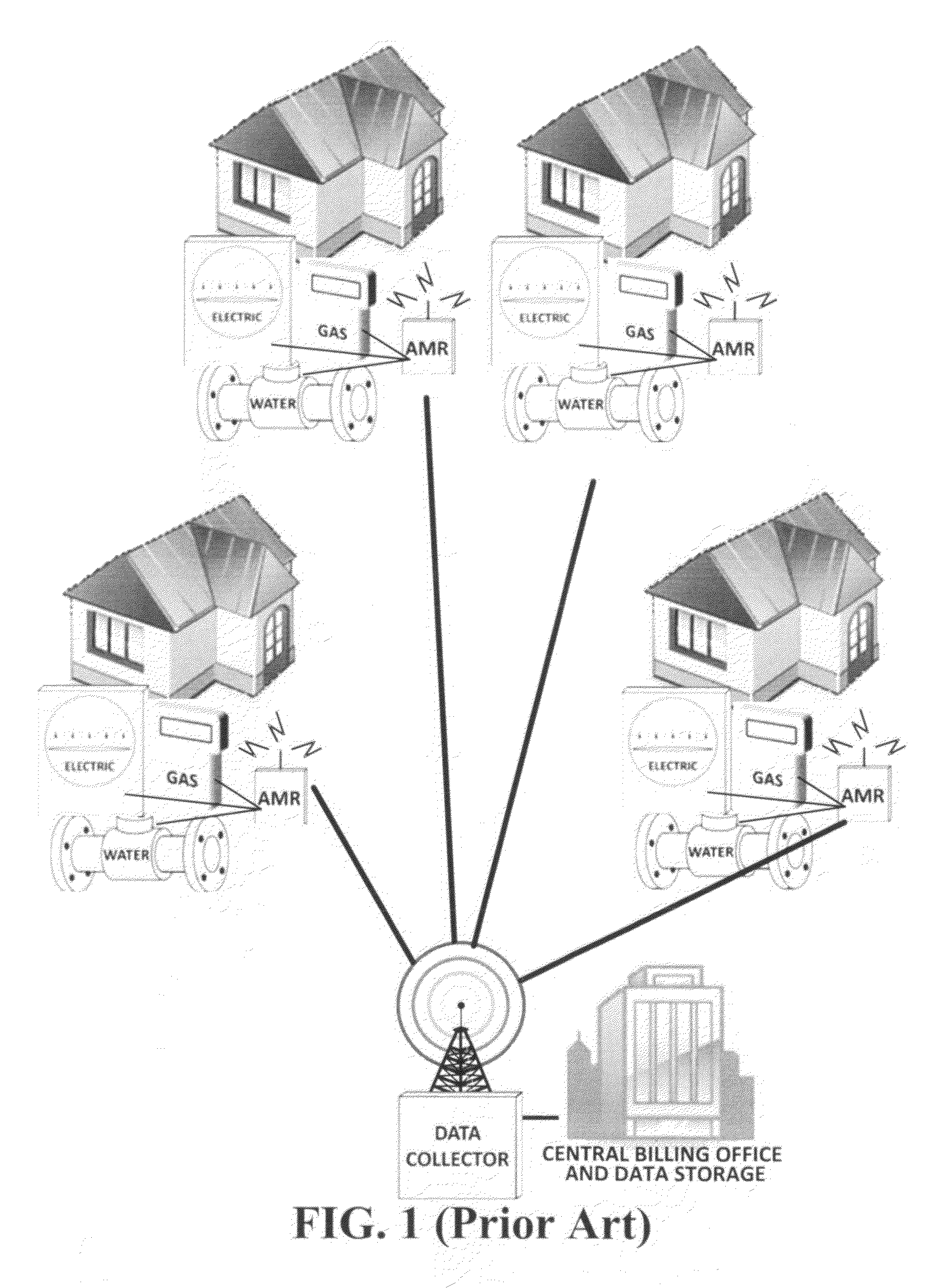

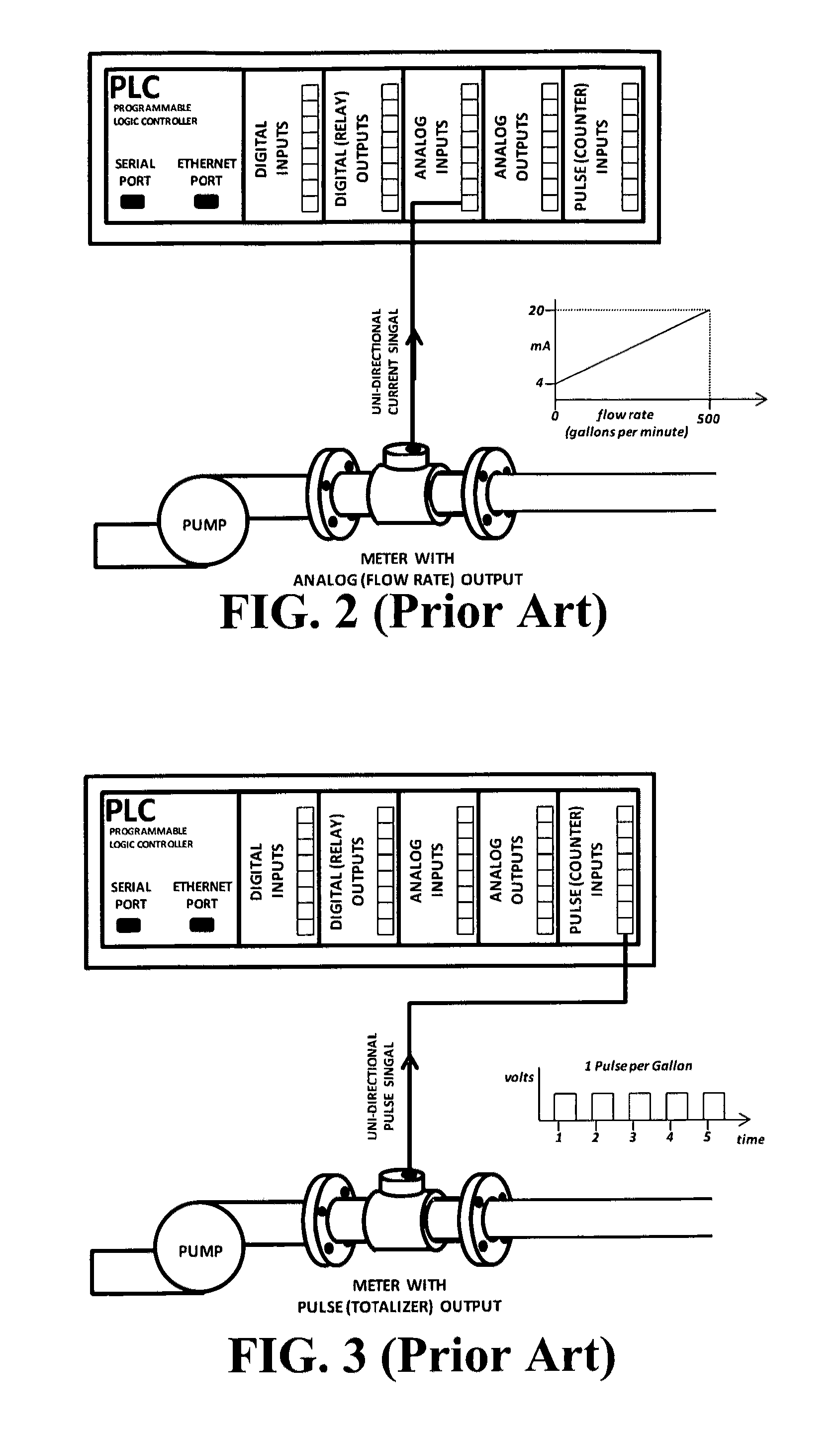

[0073]Referring now to the drawings, there is shown in FIGS. 1-3 block representations of the prior art and in FIG. 4 a preferred embodiment of the supervisory control and data acquisition protocol converter 10 and in FIGS. 5-42 associated elements of the preferred embodiment of the supervisory control and data acquisition protocol converter 10. The apparatus 10 in conjunction with an encoded register 15 meter 14 allows an industrial monitoring and control system 88 such as a SCADA (Supervisory Control And Data Acquisition) system to seamlessly interface with the aforesaid encoded registers 15. The present art apparatus 10 has firmware or a program which formats data and information received from the encoded register 15 meter 14 into a format and / or register location which is generally accepted by the SCADA system. The format and / or register location includes but is not limited to totalization information, flow information, and fault information.

[0074]The preferred embodiment has tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com