Safety sealed reservoir cap

a reservoir cap and safe technology, applied in the field of beverage, can solve the problems of increased raw material costs for beverage producers, impracticality of mixing with common plastic water bottles, and increased raw material costs, so as to prevent tampering, contamination, and less raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

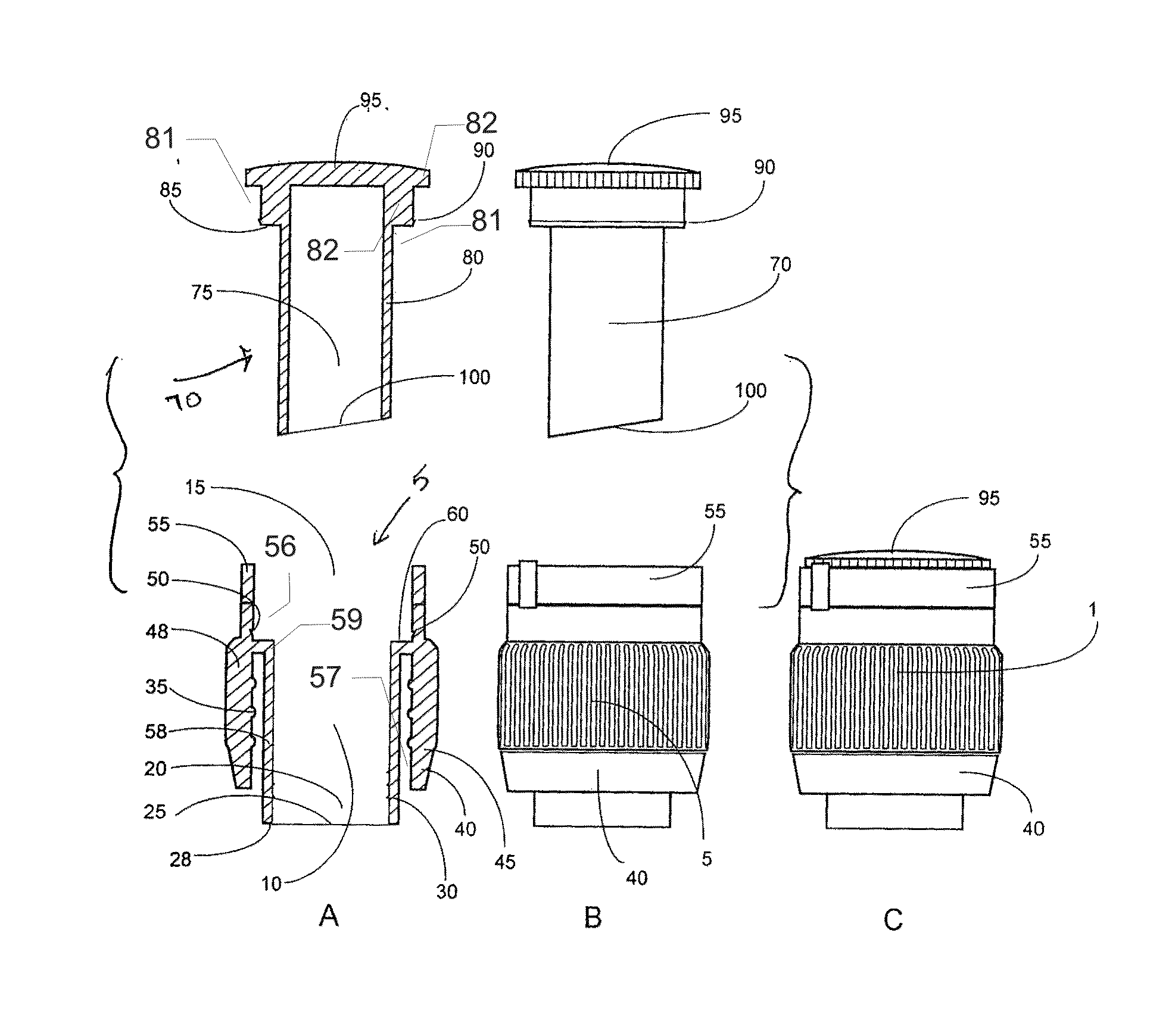

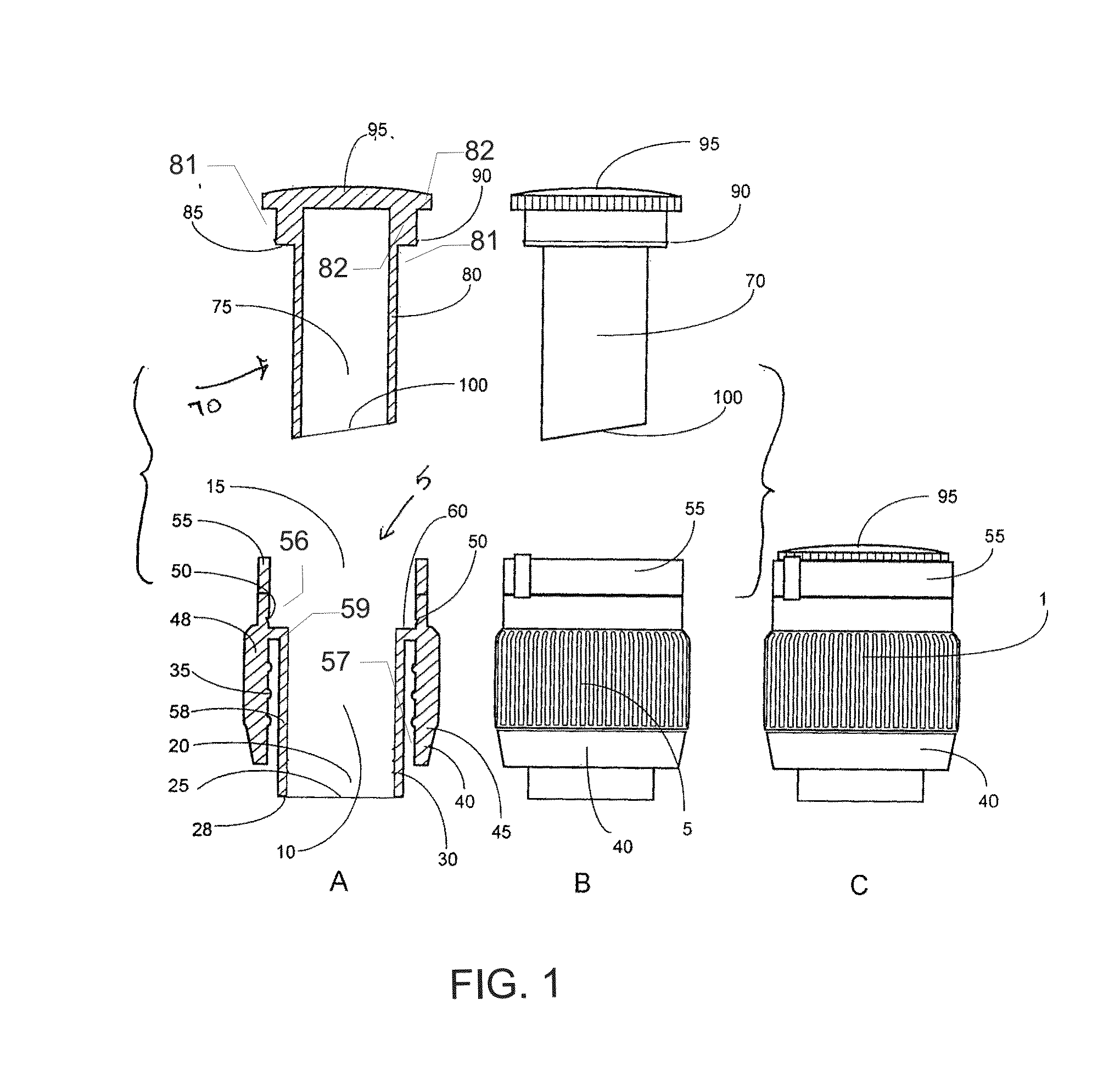

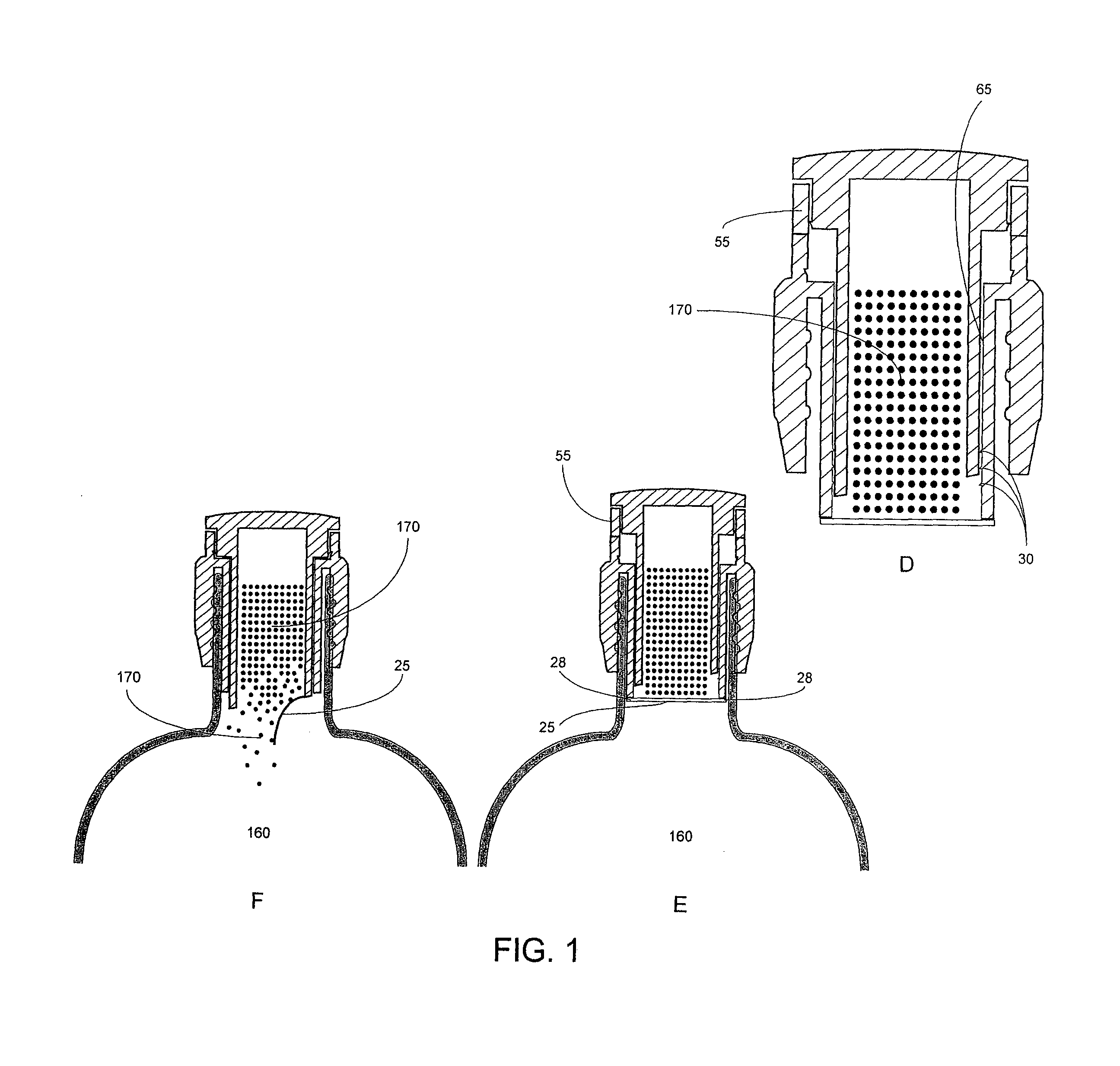

Image

Examples

example

[0078]The following are non-limiting examples of the present writing. A bottled water producer desires to add beverage additives, including flavoring, fruit concentrates, sweeteners, vitamins, minerals, and herbal supplements to water. The producer does not desire to mix the beverage additives with the water when the bottled water is produced, because the flavors of the beverage additives, when combined with water, may change taste during prolonged exposure to a plastic bottle. Furthermore, the water and flavored drink mix (including any sweetening agents) may degrade the vitamins and herbal supplements (and in some cases such as vitamin C, rapidly degrade). The bottled water producer would thus be required to add additional vitamins and herbal supplements to the beverage when produced, increasing costs. After a determined period of time (the expiration date) less than the labeled amounts of vitamins and herbal supplements will be present in the beverage, thus shortening the shelf l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| oval shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com