Module integrated solar position sensing device for concentration photovoltaic devices

a technology of photovoltaic devices and modules, applied in photovoltaics, solar trackers, direction finders, etc., can solve the problems of increasing deployment costs, reducing the overall performance of cpv systems, and cpv systems that require costly optics (lenses or mirrors), so as to reduce the installation and commissioning costs of cpv systems, reduce component redundancy and cost, and increase system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

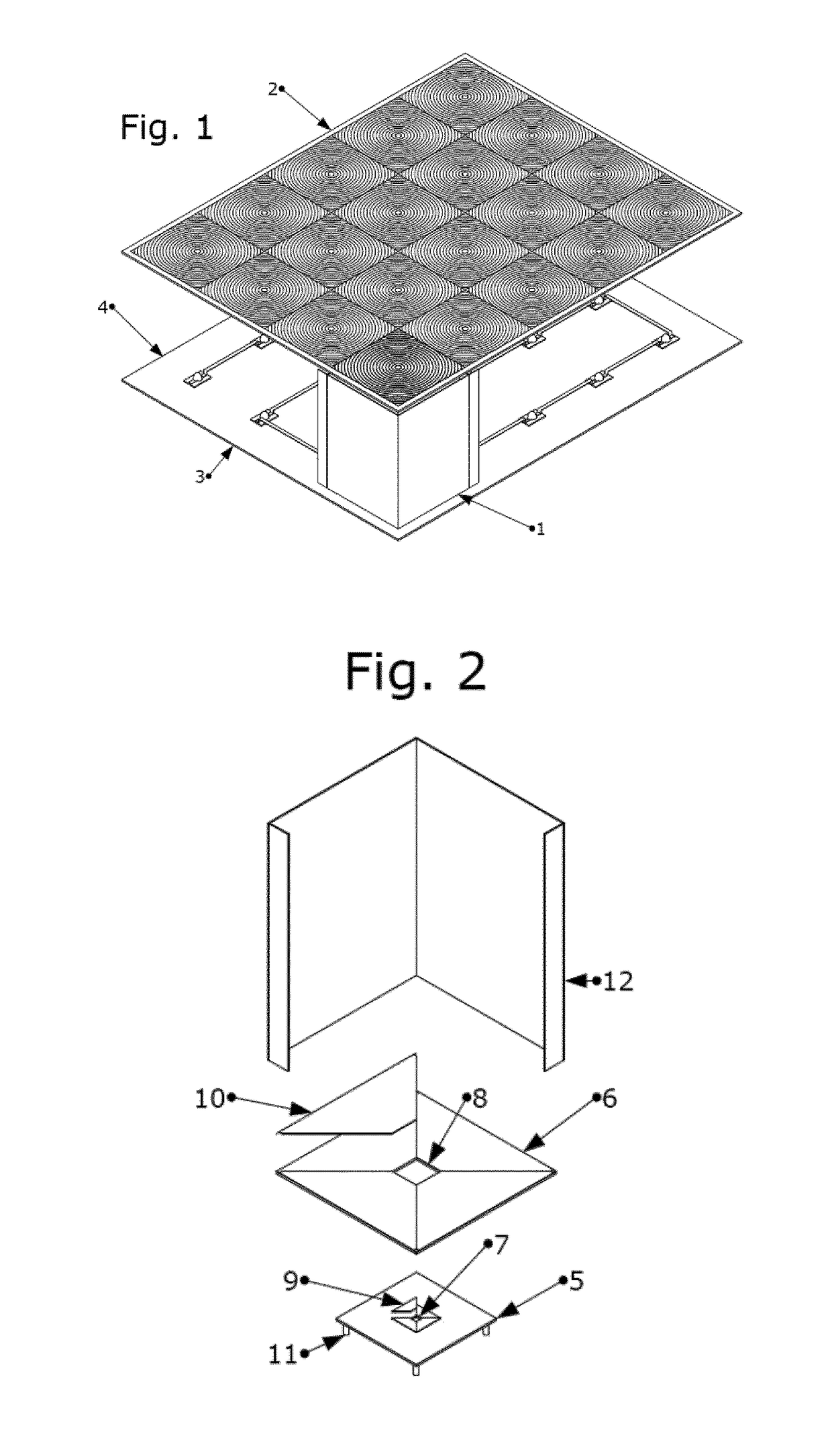

[0037]FIG. 8 is a general overview of a CPV system 800 according to one embodiment of the present invention. The CPV system 800 comprises a CPV device 810 and a sensing device 820, or module integrated solar position sensor MISPS, integrated within a single module. In other words, the sensing device is integrated within the CPV device.

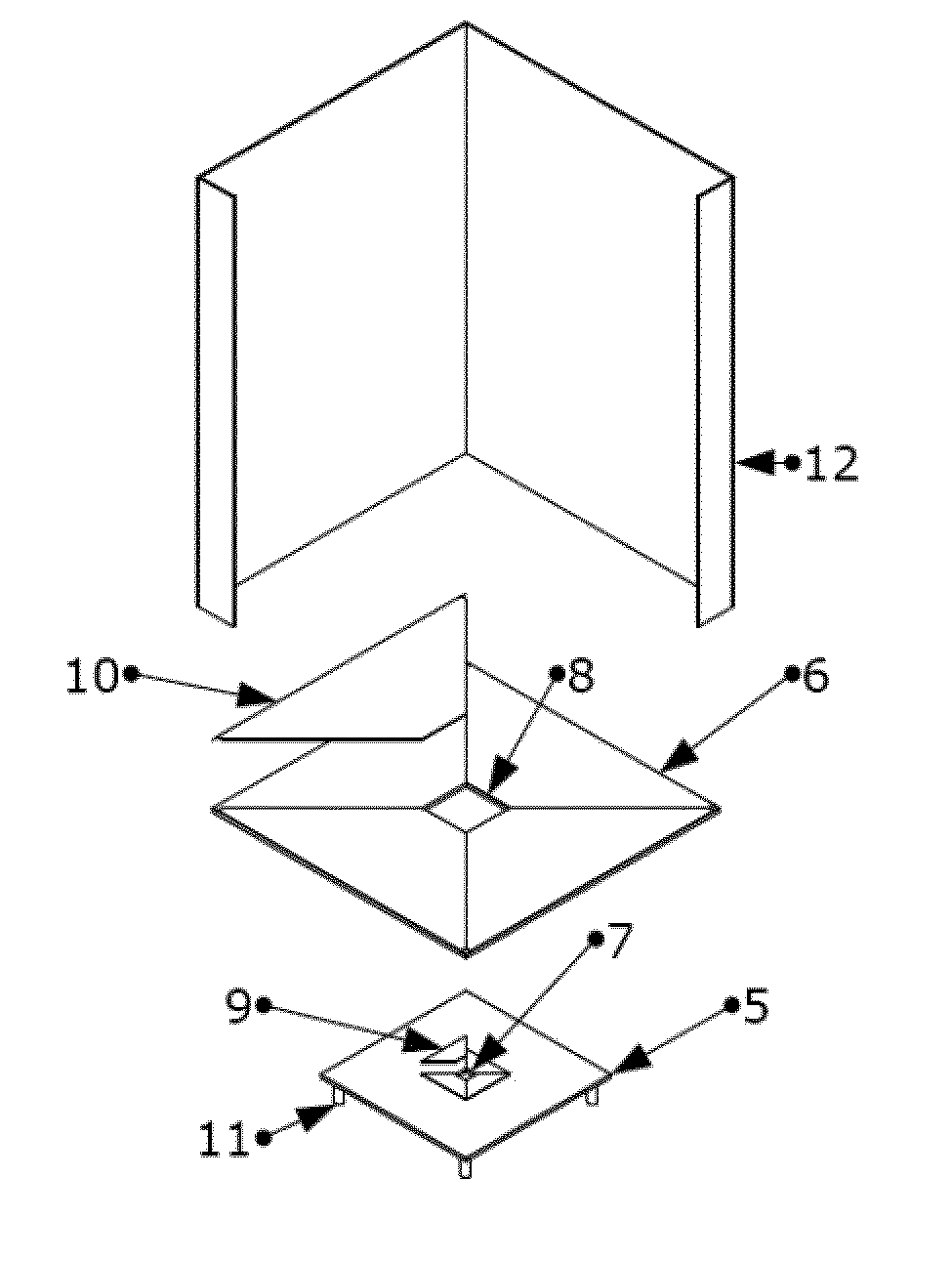

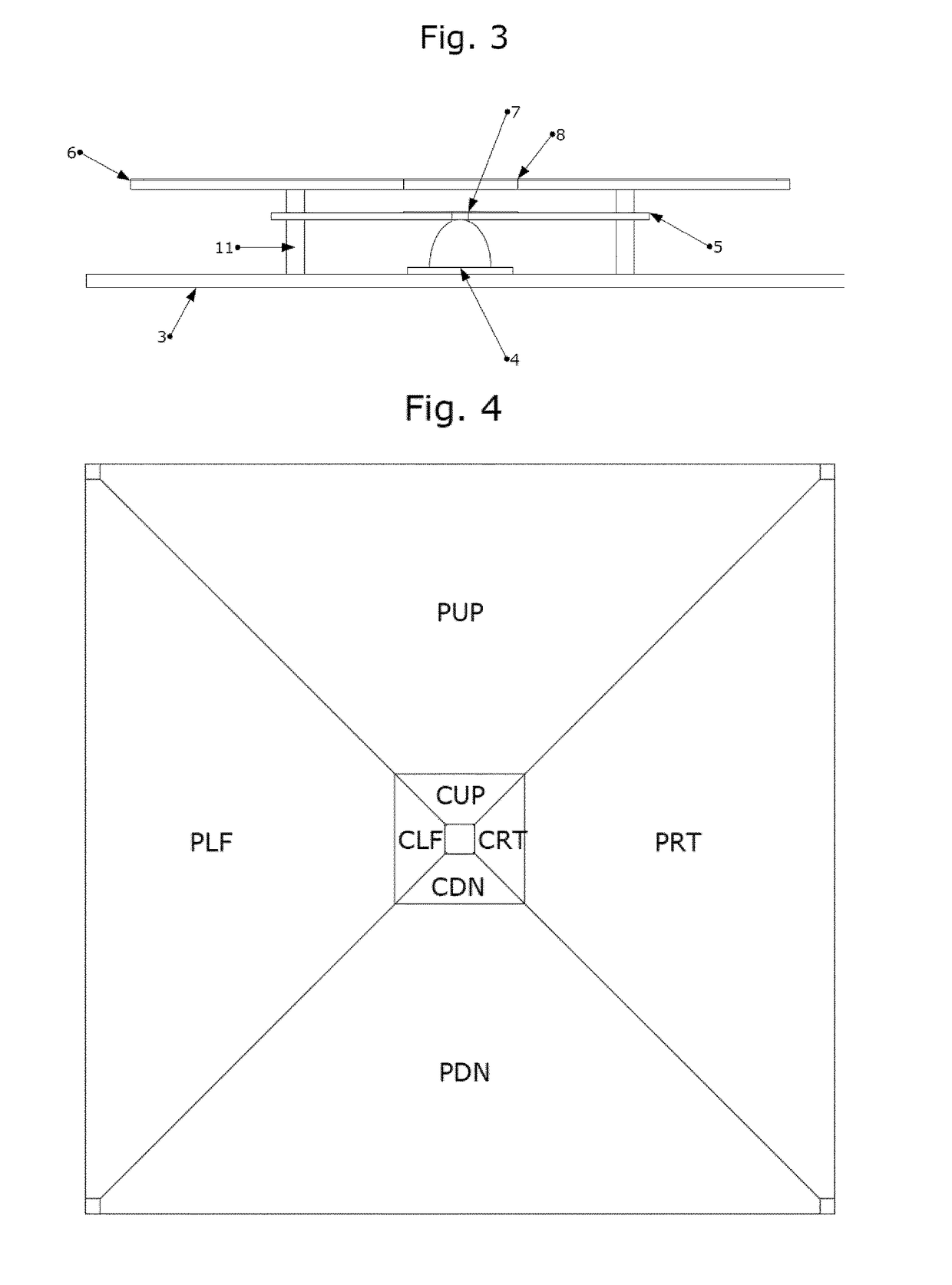

[0038]FIG. 1 is another view of the CPV system, or module, according to one aspect of the present invention. The sensing device 1 is integrated within the CPV device, together forming a single module. The sensing device is located in between a panel composed of a plurality of primary optical elements POE 2 and a receiver panel 3 comprising a plurality of CPV receivers 4. In order to allow the internal components to be shown, the CPV module walls have been omitted. It can be observed that the plane formed by the plurality of POE elements 2 and the receiver panel 3 are parallel to each other. The sensing device is installed on top of one of the CPV recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com