Air intake arrangement for internal combustion engine

a technology for air intake and internal combustion engines, which is applied in the direction of machines/engines, combustion-air/fuel-air treatment, electric control, etc., can solve the problems of difficult effective inducing swirling, difficult to reduce the acceleration response of fuel supply, and the obtained swirl is sometimes weaker and sometimes stronger than expected, so as to reduce the deposition ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Hereinbelow, embodiments of the present invention are explained with reference to the drawings.

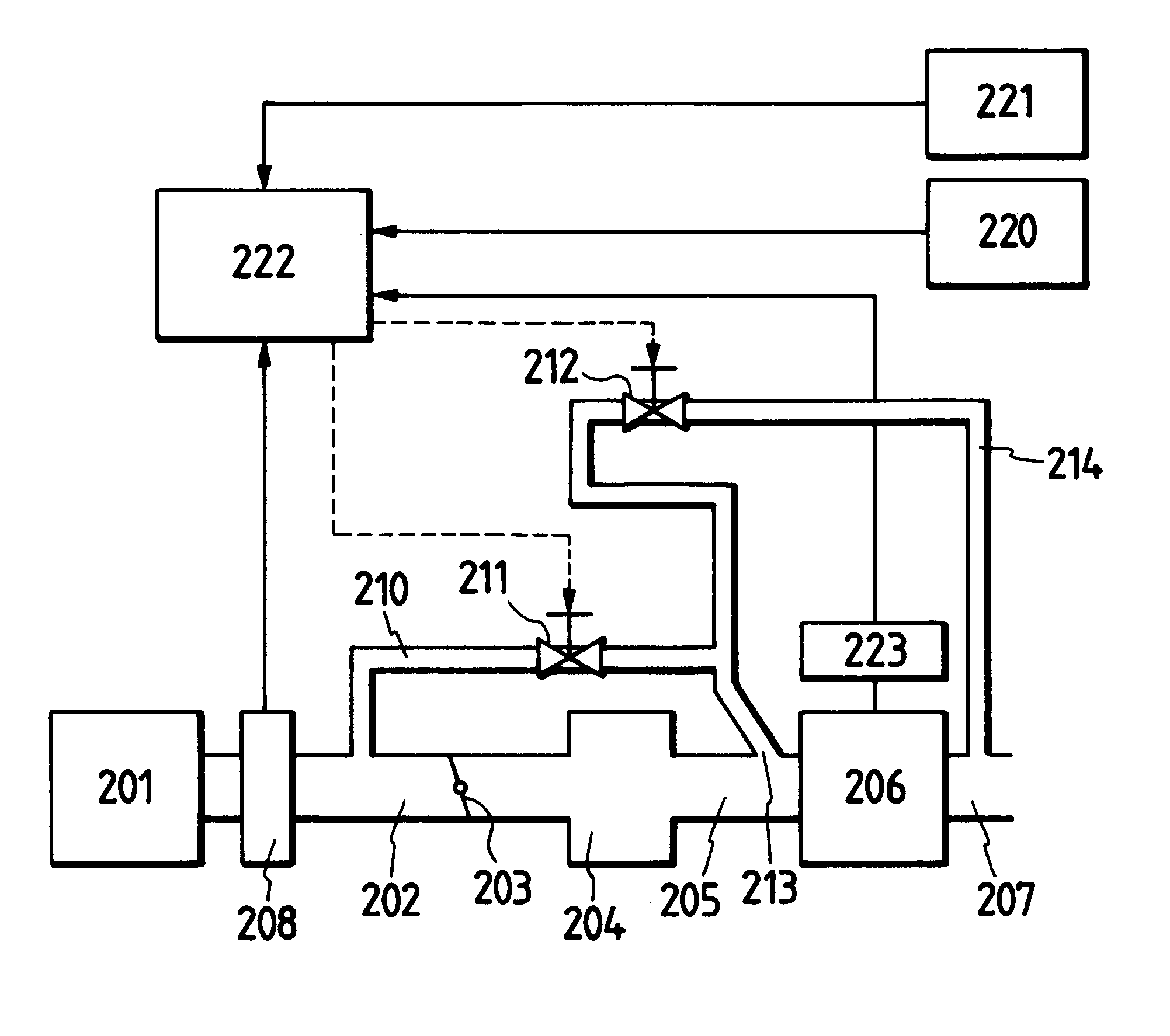

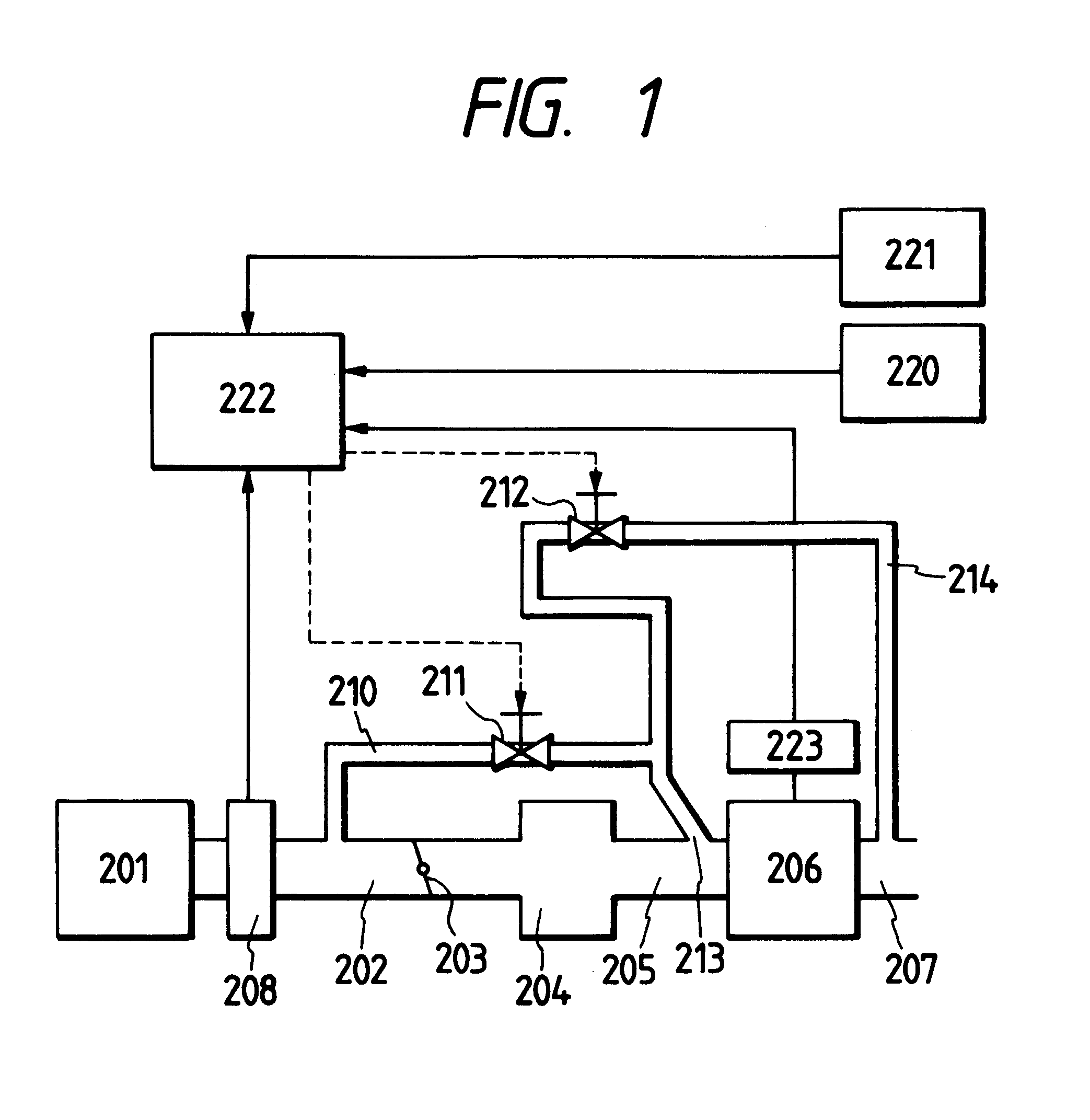

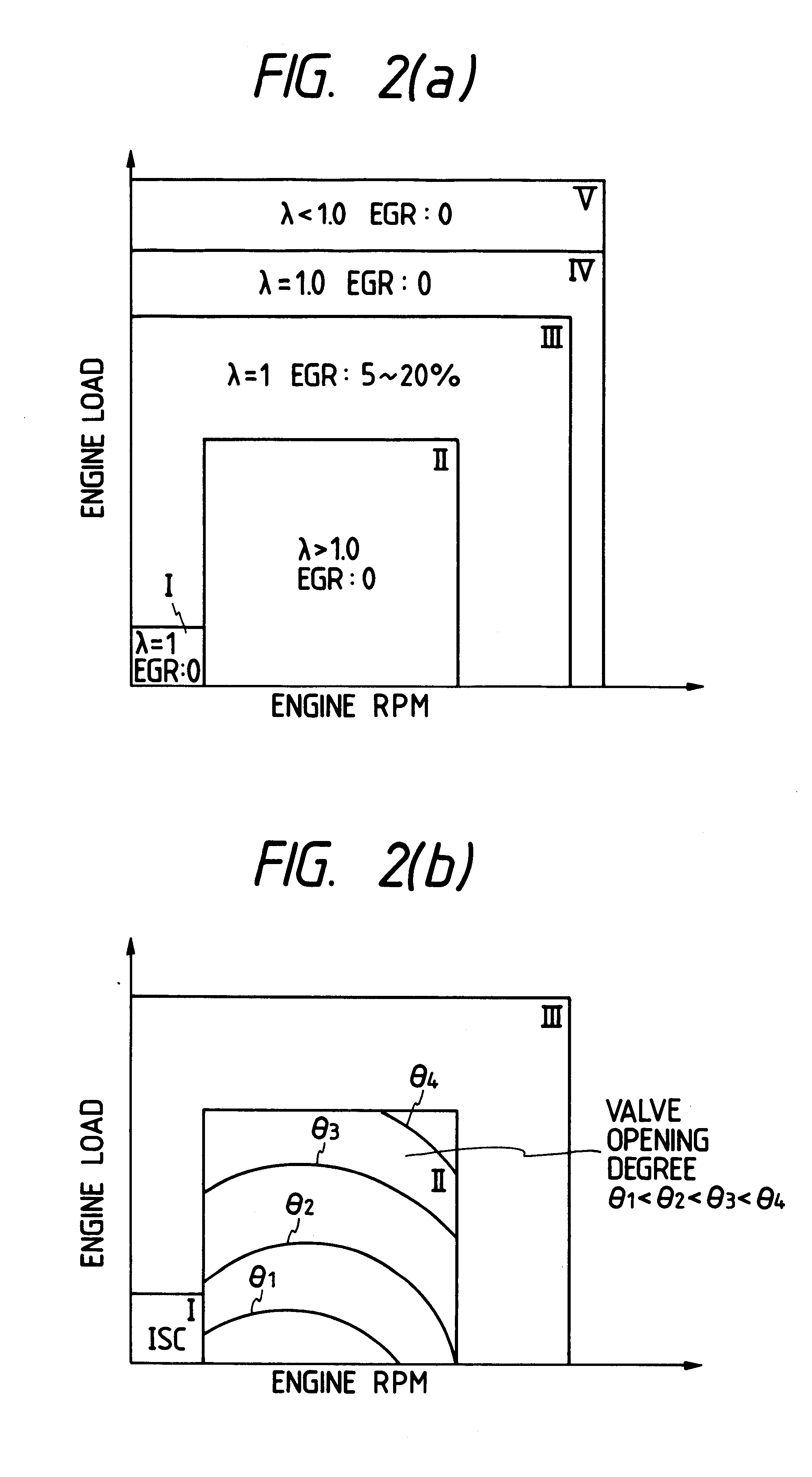

FIG. 1 shows one embodiment of the present invention. Inlet air is introduced from an air cleaner 201, and the flow rate thereof is measured by an air flow meter 208. An amount of air passing through a main passage 202 is adjusted by a throttle valve 203 and then distributed for respective engine cylinders from a collector 204 and thereafter introduced into an engine 206 via respective independent air intake conduits 205. In the present embodiment, an auxiliary gas passage 210 is provided in parallel with the respective independent air intake conduits 205. Air flow rate passing through the auxiliary gas passage 210 is adjusted through a control of an intake air control valve 211 by a computer 222 based on a signal from an acceleration pedal opening degree detecting means 221, an ON / OFF signal from engine accessories 220, a signal from an engine rpm detecting means 223 and an intake air amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| time lag | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com