Inverted board mounted electromechanical device

a technology of electromechanical devices and inverters, which is applied in the direction of relays, cross-talk/noise/interference reduction, and association of printed circuit non-printed electric components, can solve the problems of low overall profile of circuit boards, and achieve the effect of convenient surface mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

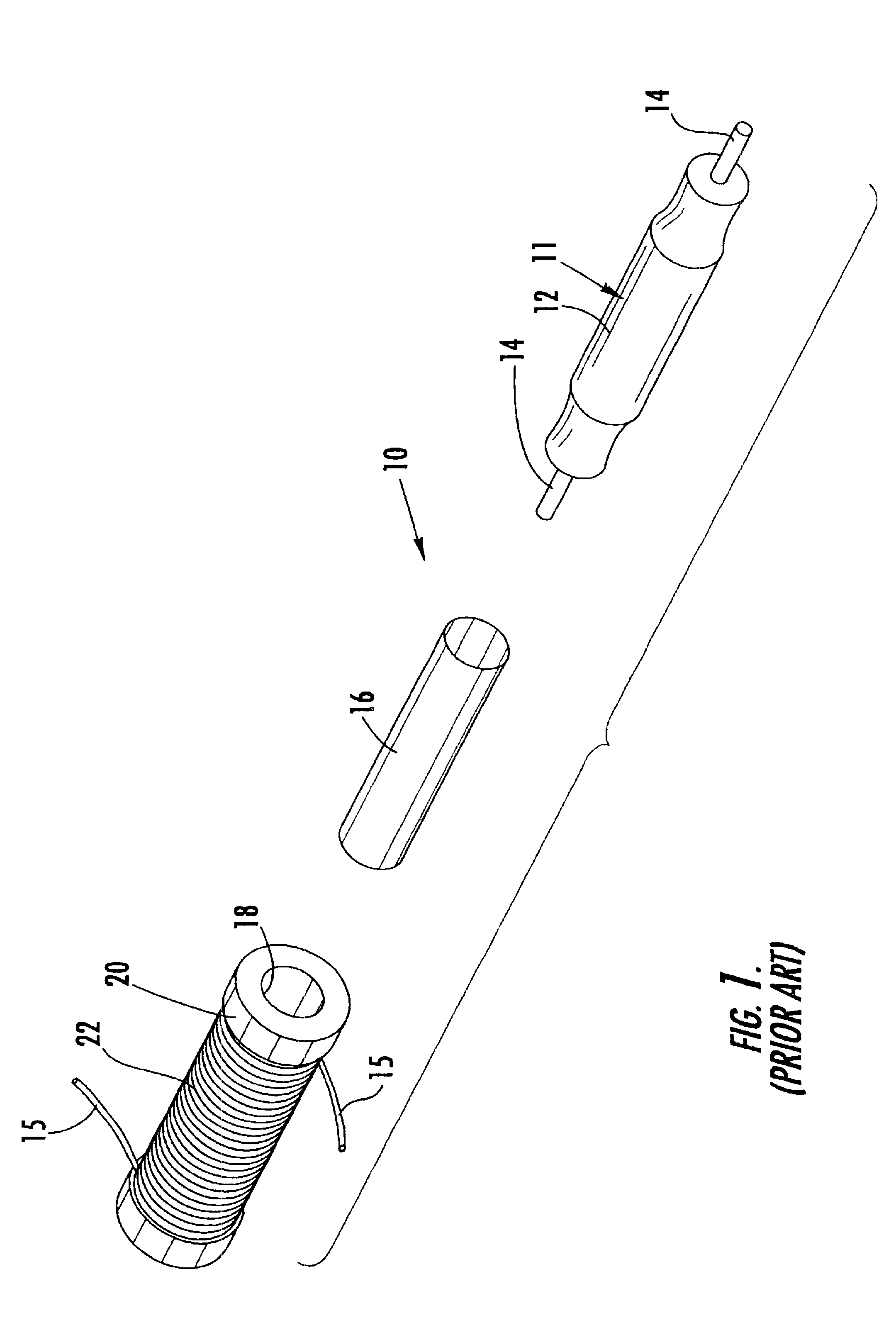

Turning first to FIG. 1, a perspective view of a prior art reed switch configuration 10 is shown. A known reed switch 11 includes a glass envelope 12 as well as two signal leads 14 emanating from opposing ends of the reed switch 11 and coil termination leads 15. The construction of a reed switch 11 is so well known in the art, the details thereof need not be discussed. A shield conductor 16, commonly made of brass or copper, is provided in the form of a cylindrical sleeve which receives and houses the reed switch 11. The reed switch 11 and shield 16 are housed within the central bore 18 of a bobbin or spool 20. About the bobbin 20 is wound a conductive wire 22. As a result, a co-axial arrangement is formed to protect the reed switch 11 device and to control the impedance of the environment and to improve the overall transmission of the signal. The reed switch 11, shield conductor 16 and bobbin 20 are shown in general as cylindrical in configuration. It should be understood that vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com