Cam-type retainer clip for heat sinks for electronic integrated circuits

a technology of electronic integrated circuits and retainer clips, which is applied in the direction of machine supports, furniture parts, lighting and heating apparatus, etc., can solve the problems of retainer clips being unloosed, retainer clips may be prone to loosening, and retainer clips may be easy to loosen, etc., to achieve low cost, substantial assembly integrity, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

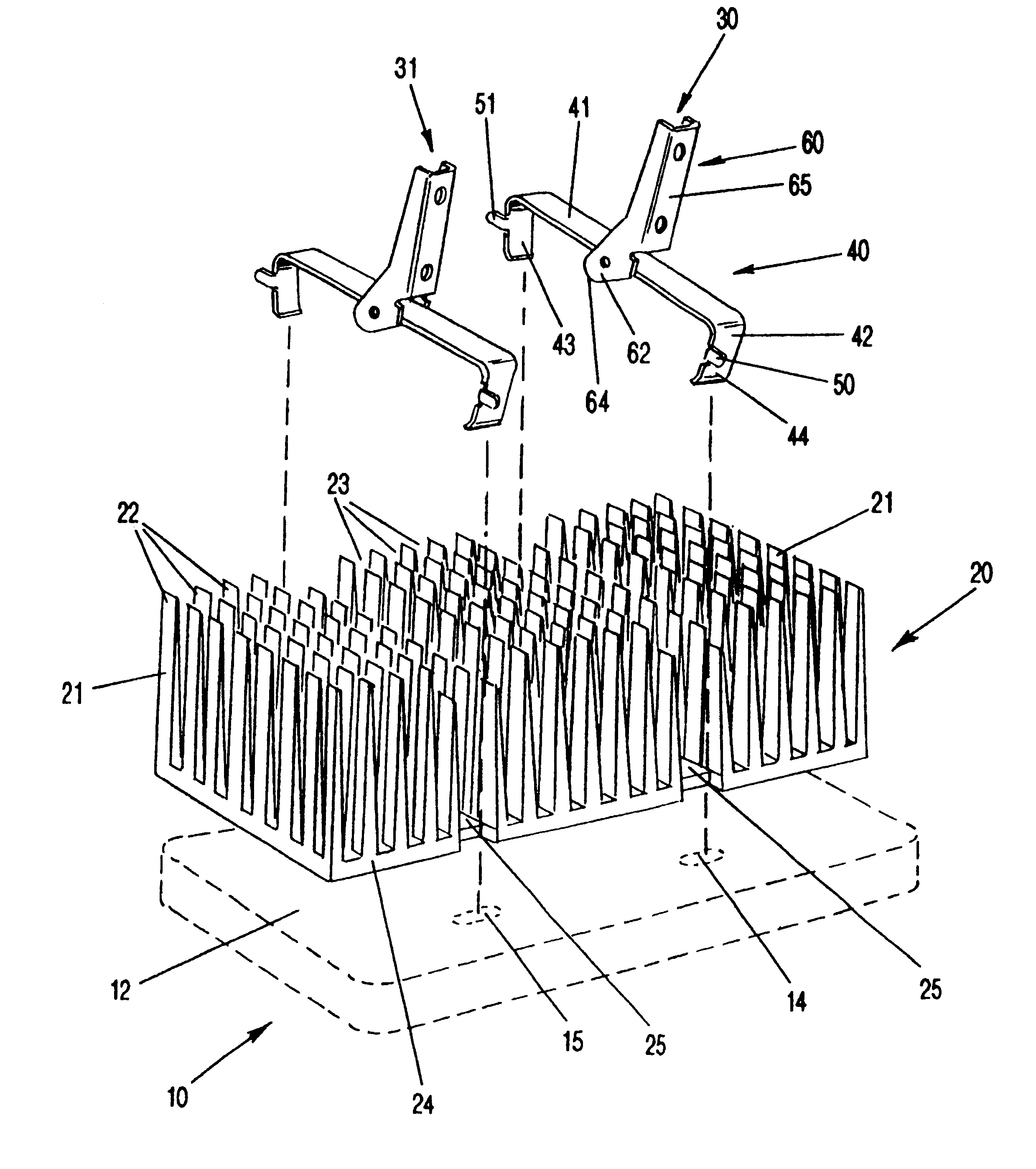

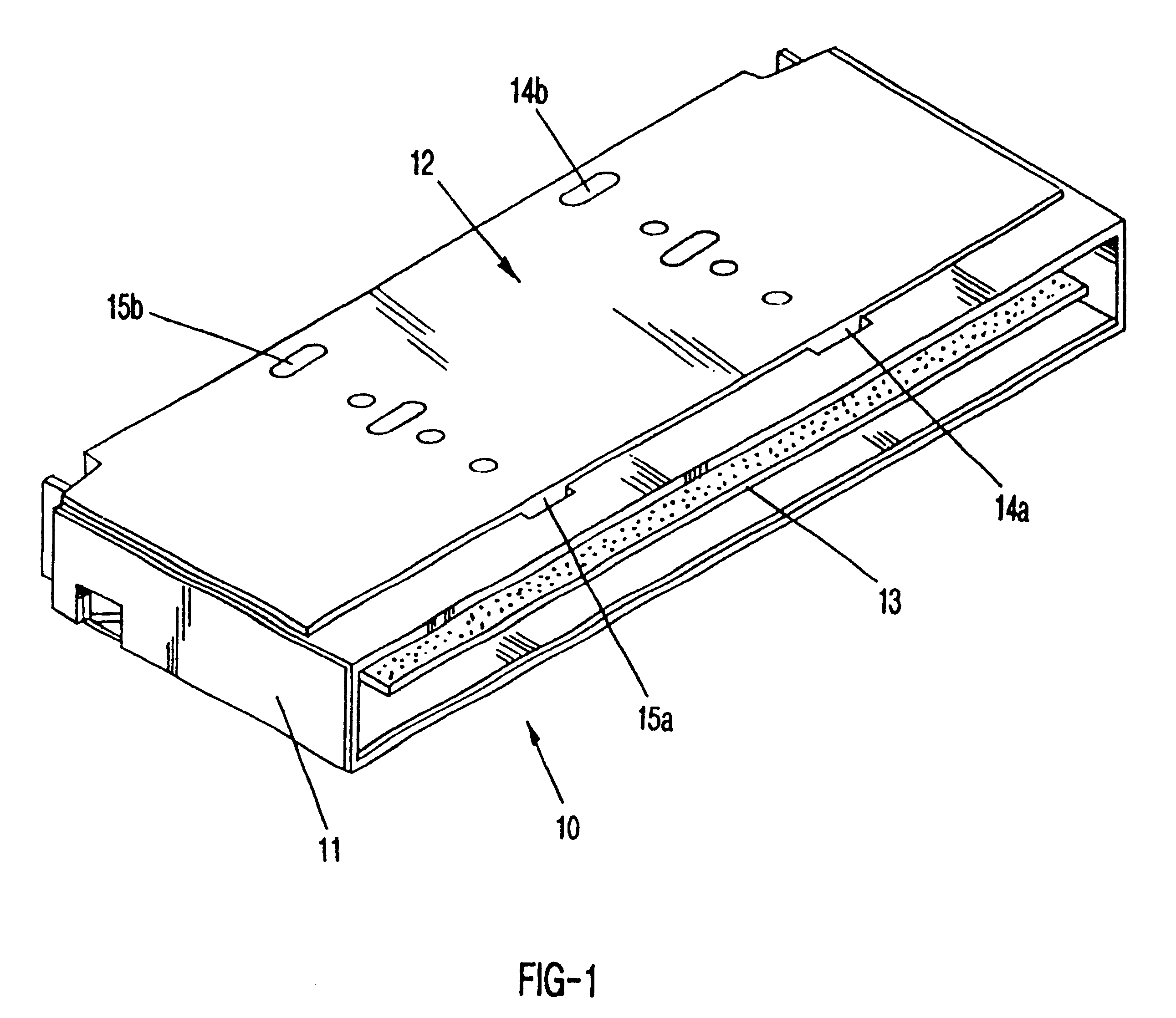

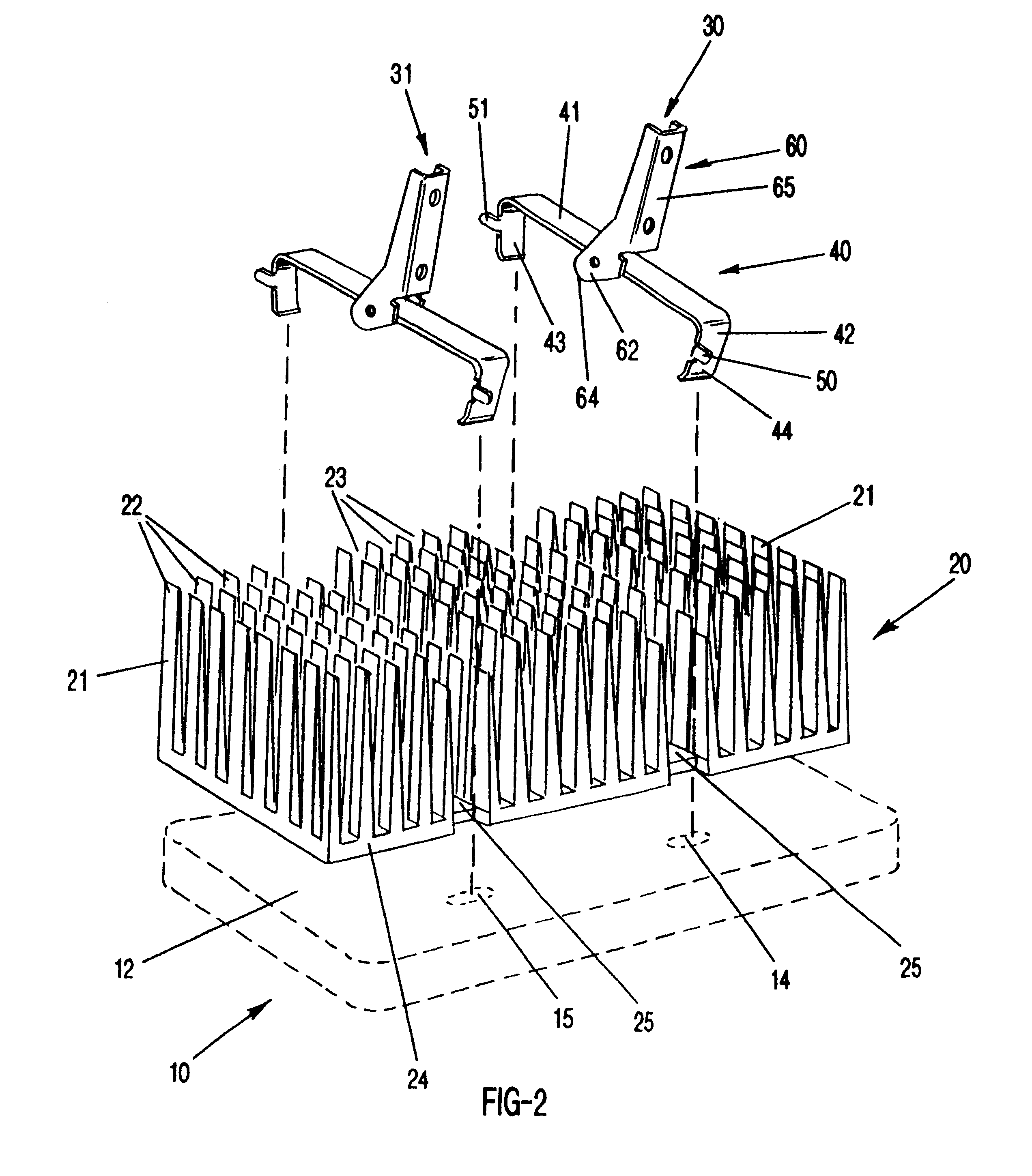

the present invention will be shown and described in conjunction with a semiconductor module 10 which has a case 11 including a wall 12 defining the upper surface of case 11. The module is merely representative of a housing that contains at least one semiconductor device; the term "housing" includes modules, cartridges, the semiconductor device itself, or the semiconductor device mounted in a socket. Within the module is mounted a printed circuit board 13 which may include one or more semiconductor devices (not shown). A portion of the upper major wall 12 is made of metal or other high heat-conducting material and is intended to engage or interface with a heat sink for dissipating heat from the semiconductor devices and the module as a whole. To assist in the engagement of a heat sink to the wall 12, the major wall 12 is provided with a plurality of openings shown at 14 and 15. In the particular module configuration shown, two holes 14A, 15a are adjacent one longitudinal edge and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com