Automatic visual inspection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

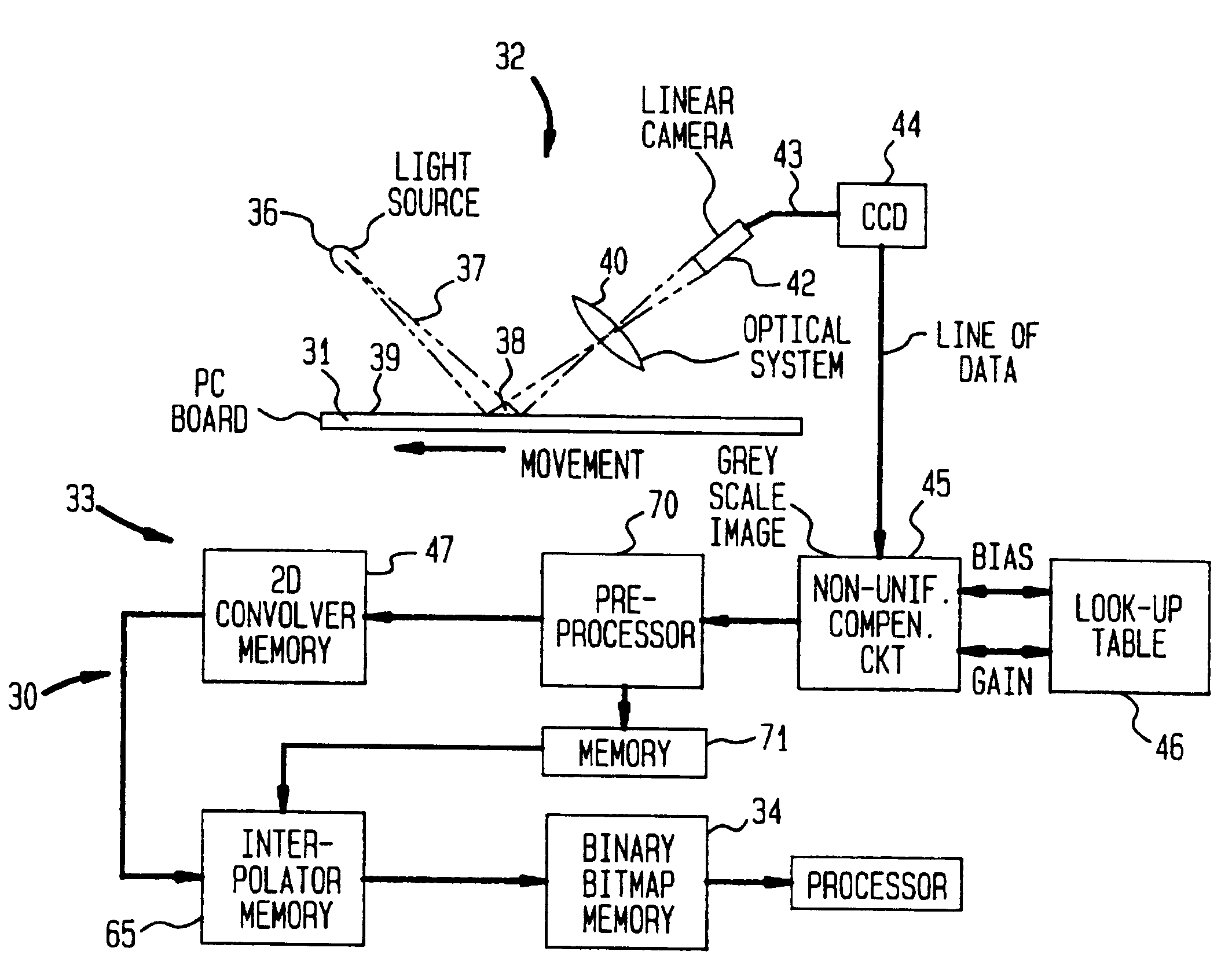

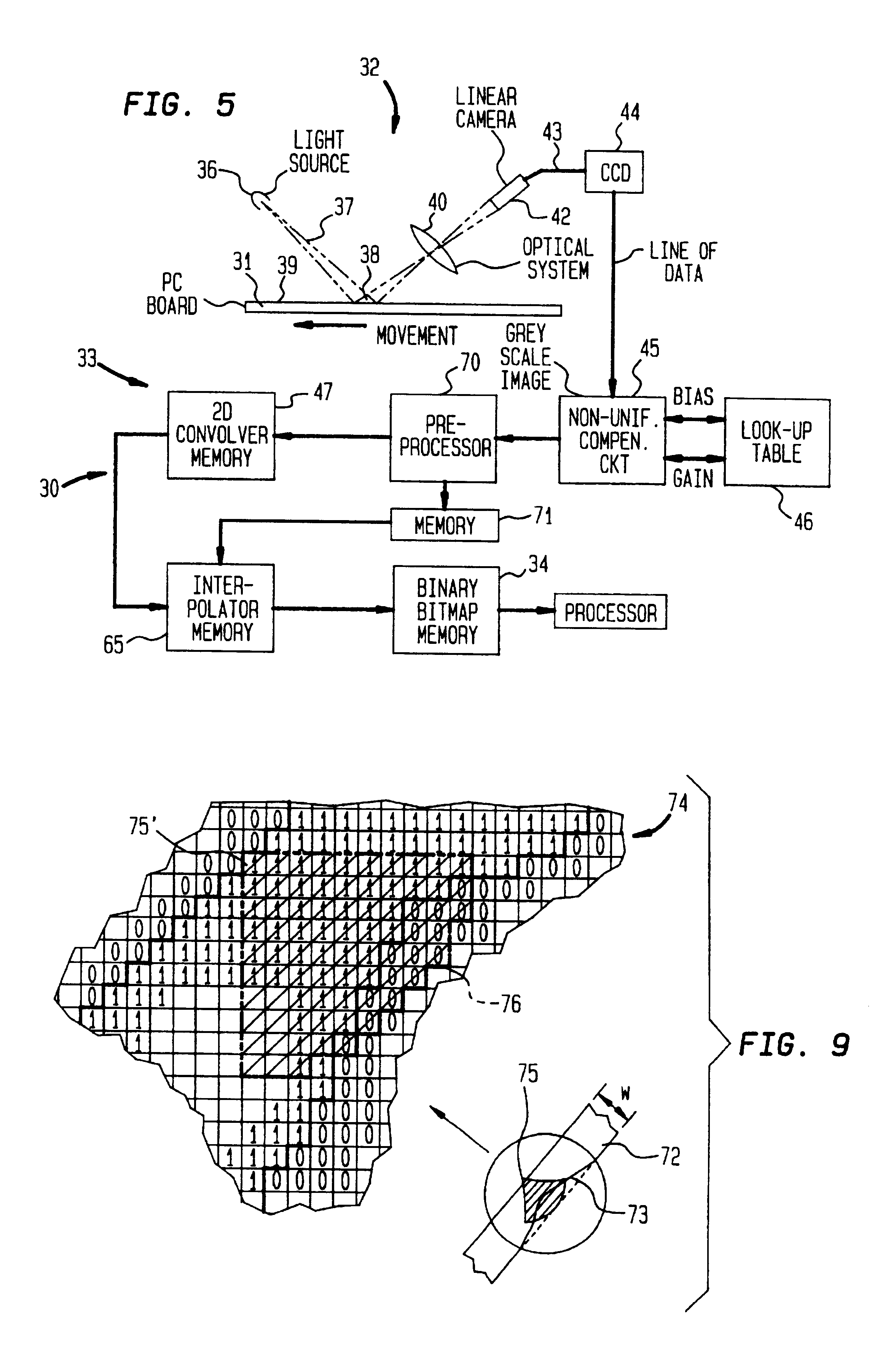

Embodiment Construction

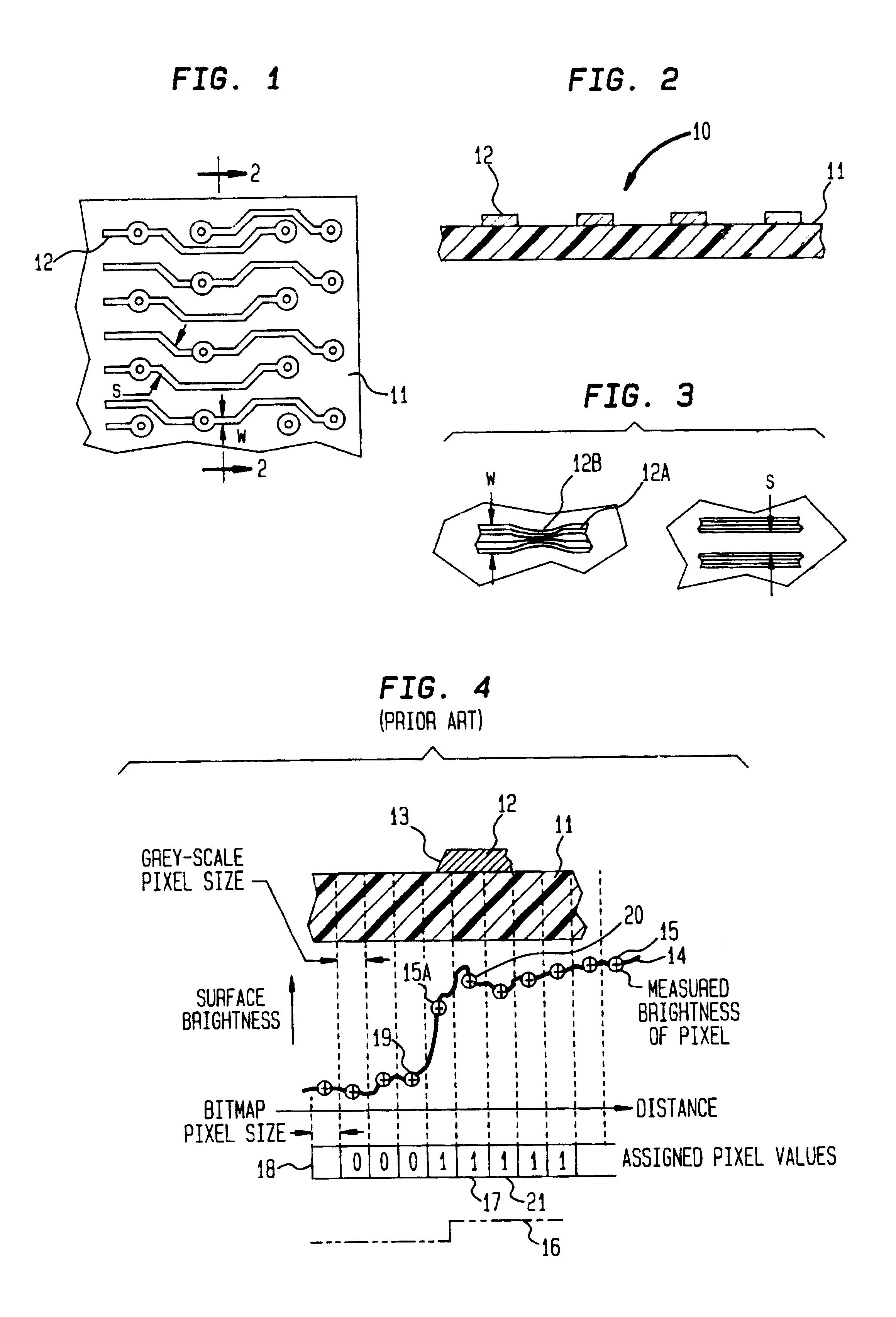

Referring now to the drawing, reference numeral 10 designates a conventional printed circuit board comprising substrate 11 on one surface of which are deposited conductive tracks or lines 12 in a manner well known in the art. A typical board may have 3 mil lines, and spacing between lines of a comparable dimension.

As is well known, the technique of depositing lines 12 on substrate 11 involves a photographic and etching process which may produce a result shown in FIG. 3 where line 12a, of width w has a reduced portion at 12b. The cross section available for conduction in reduced portion 12b may be insufficient to permit proper operation of the electronic components associated with the printed circuit board; and for this reason a board having a line of a width less than some predetermined value would be rejected, or at least noted. As boards get more and more complex, detecting breaks in lines, or lines with reduced width, becomes more and more difficult.

The photoetching process invol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com