Apparatus and methods for cooling slot step elimination

a technology of apparatus and cooling slot, which is applied in the field of apparatus and methods for reducing stress on turbine blades, can solve the problems of large stress concentration with high terminal stress, easy potential early fatigue and blade failure of trailing edge axial cracks, so as to improve the longevity and performance of the turbine blade, reduce the stress concentration, and reduce the fatigue of the airfoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

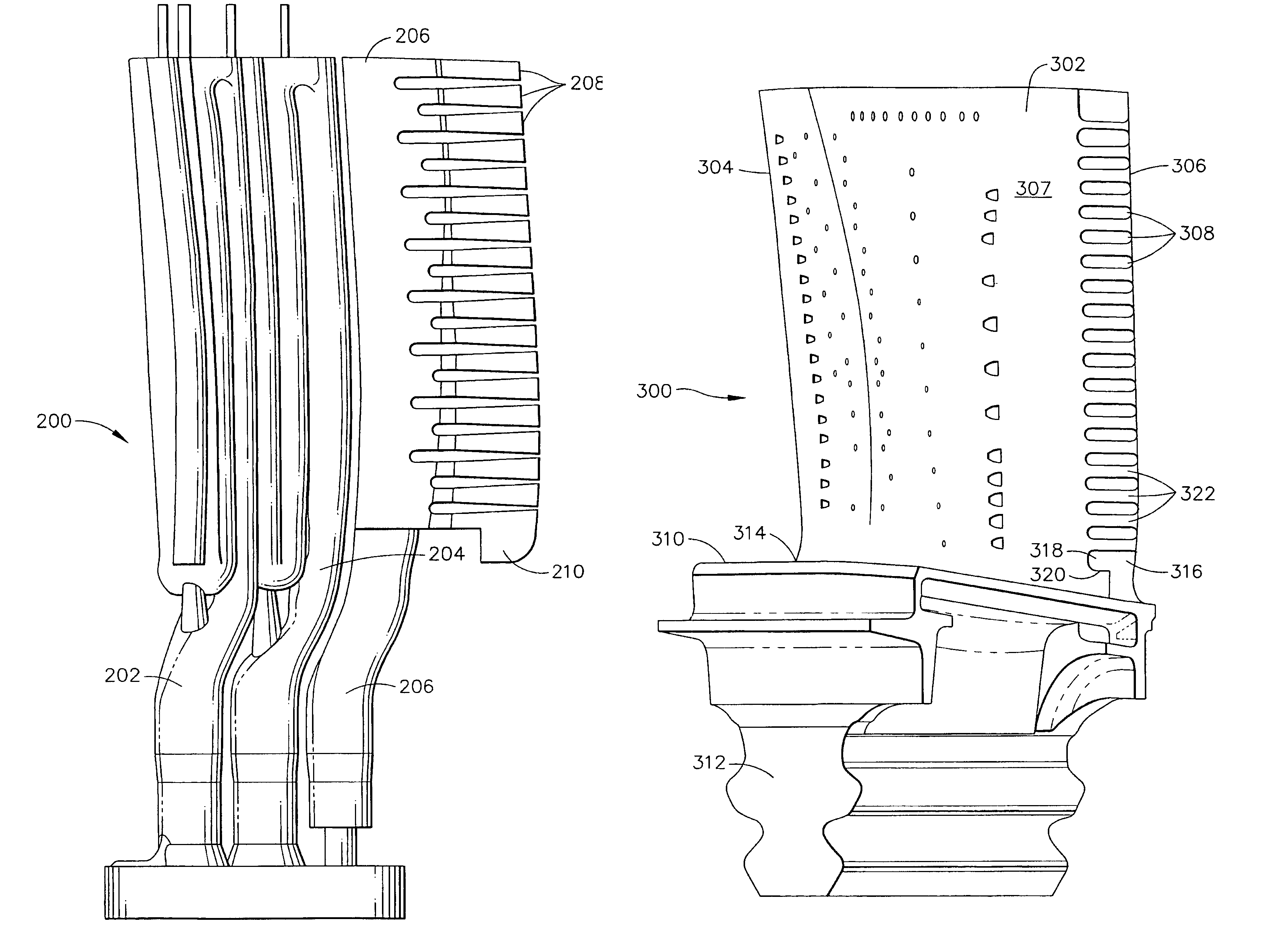

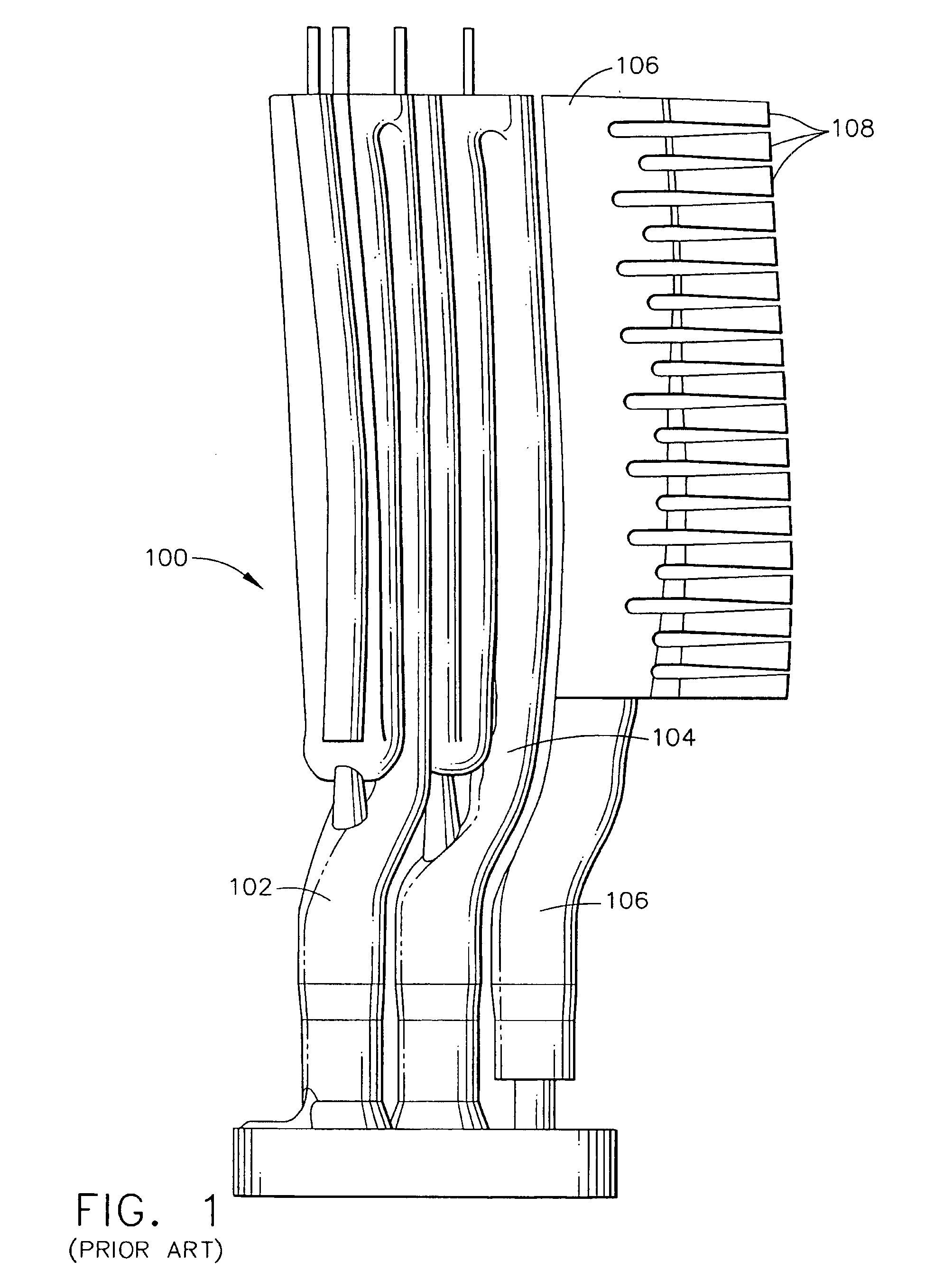

[0015]FIG. 1 illustrates a known airfoil coil 100 utilized for fabricating turbine blades (not shown). Airfoil core 100 includes a first serpentine cooling channel 102, a second serpentine cooling channel 104, an aft wedge channel 106, and a plurality of fingers 108 extending from aft wedge channel 106.

[0016]Airfoil core 100 is fabricated by injecting a liquid ceramic and graphite slurry into core die (not shown). The slurry is heated to form a solid ceramic airfoil core 100. The airfoil core is suspended in an airfoil die (not shown) and hot wax is injected into the airfoil die to surround the ceramic airfoil core. The hot wax solidifies and forms an airfoil (not shown in FIG. 1) with the ceramic core suspended in the airfoil.

[0017]The wax airfoil with the ceramic core is then coated with multiple layers of ceramic and heated to remove the wax, thus forming a cavity shell having the shape of the airfoil. The shell is the cured in a heated furnace. Molten metal is then poured into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com