Boosted air source heat pump

a heat pump and air source technology, applied in the field of air source heat pumps, can solve the problems that the potential of the power source heat pump is significant, and achieve the effect of sufficient and efficient heating and increased refrigerant pumping capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

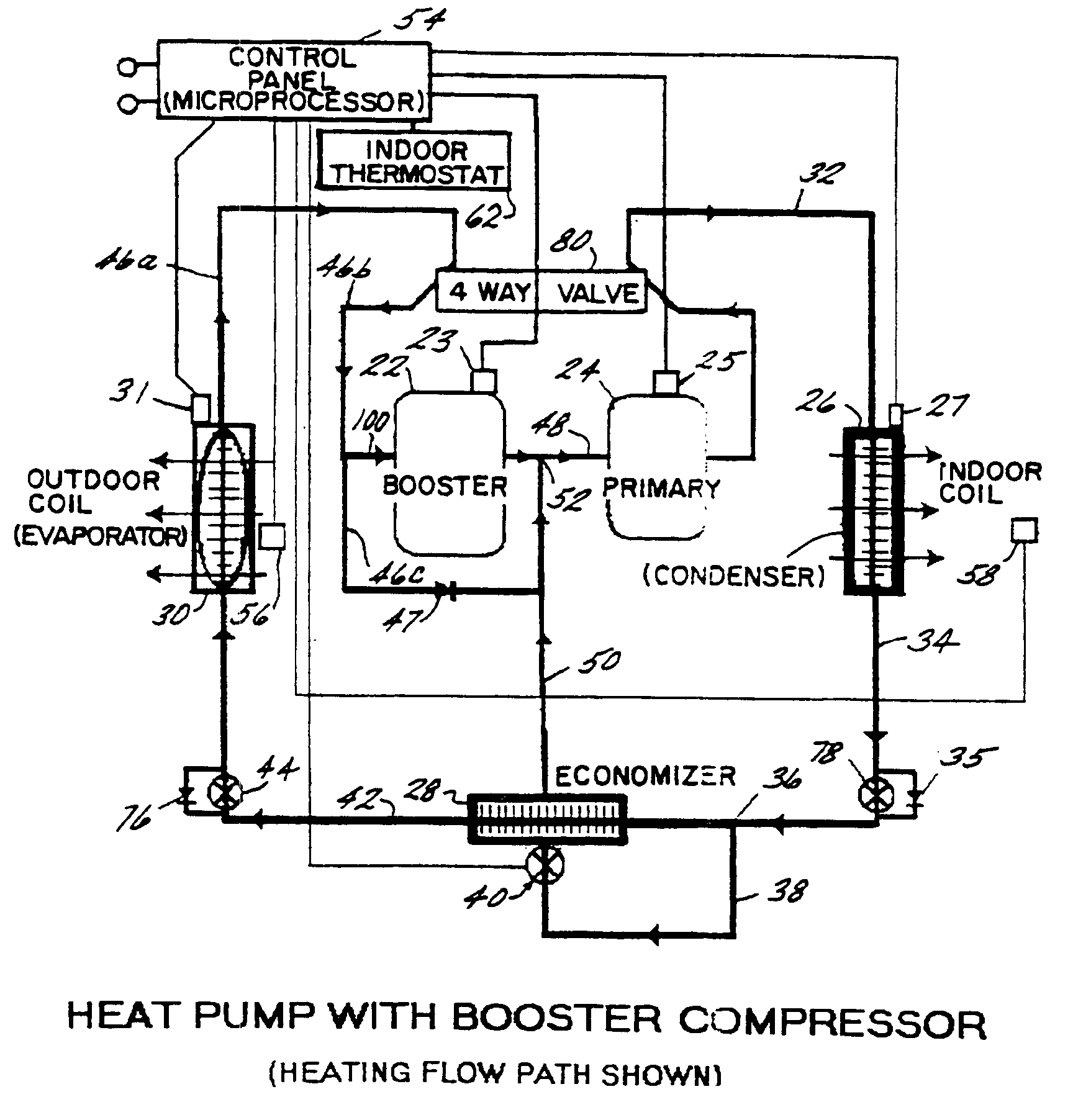

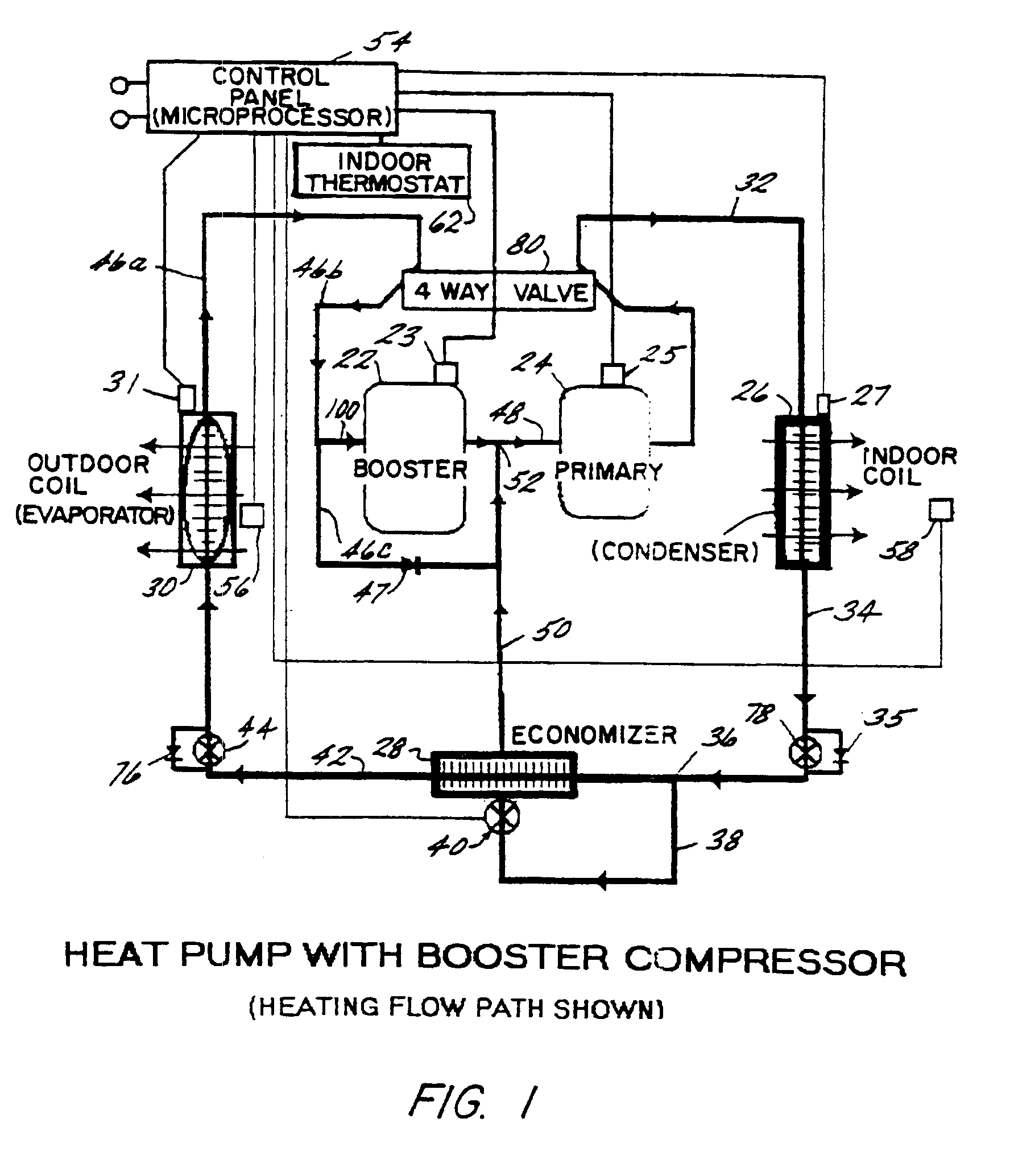

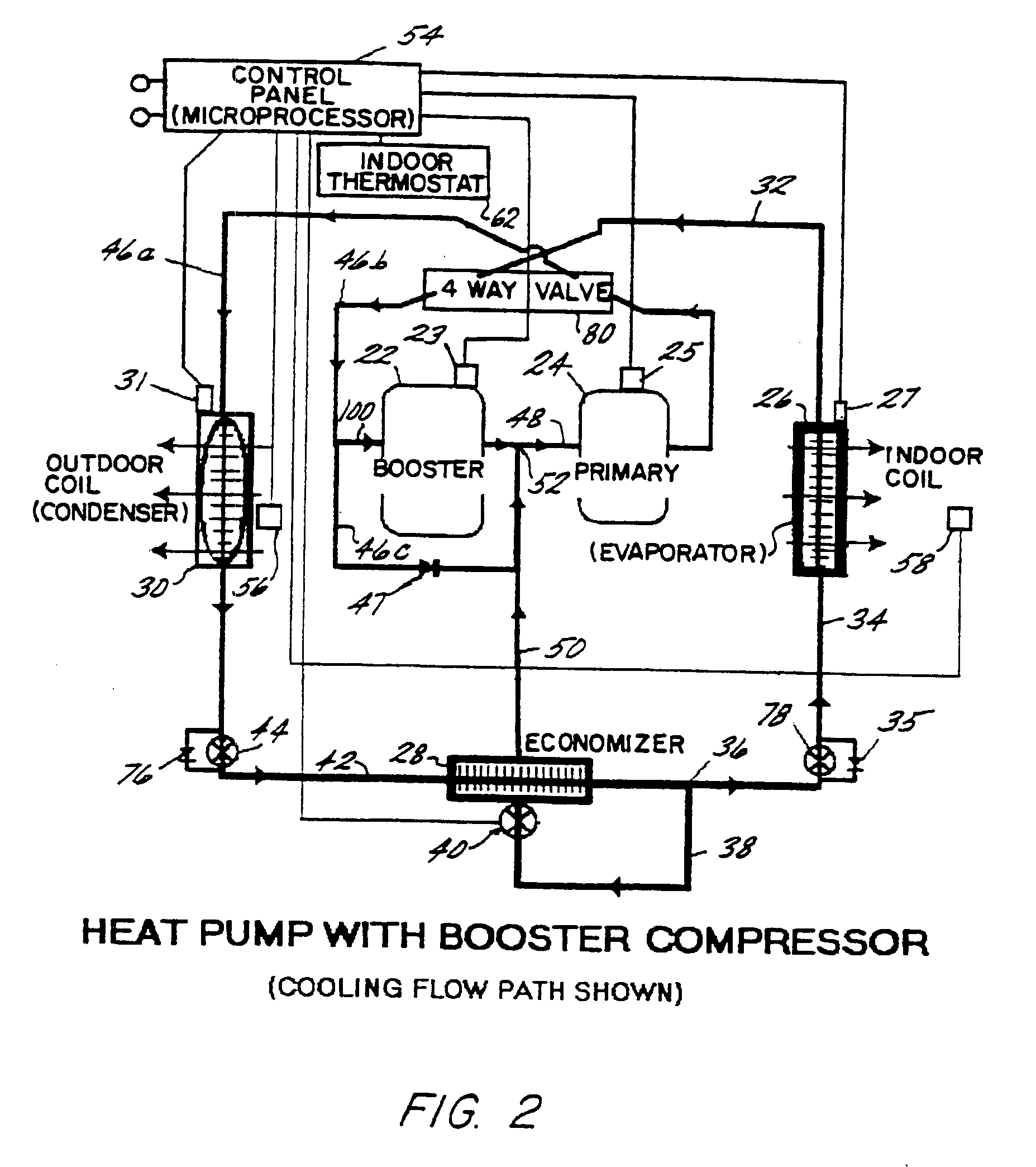

[0060]Referring now to FIGS. 6 and 7, a heating capacity chart and an exemplary operating sequence are shown. It will be recalled that thermostat 62 preferably has three stages in the heat mode. The thermostat stages signal microprocessor 54, which, in turn, sends signals to allow (i.e., control) the operation of the compressors, and / or one or both cylinders of the compressors, and / or the economizer.

[0061]Typically, the heating cycle starts when the first stage or step of indoor thermostat 62 calls for heat. When this occurs somewhere between 75° F. and above 50° F. outdoor ambient temperature, as sensed by sensor 56, one piston of primary compressor 24 is allowed to operate, i.e., is activated by a signal from microprocessor 54. Depending on the configuration, this provides 40% or 50% of the displacement of primary compressor 24. This mode of operation is identified in FIGS. 6 and 7 as 010, signifying 0 cylinder operation of the booster, 1 cylinder operation of the primary and no o...

example 2

[0068]While incorporation of economizer 28 in the system is preferred, the economizer can be omitted. In that case, the displacement ratio of the booster compressor 22 to primary compressor 24 would be increased sufficiently to realize a system capacity about that of the system with the economizer, understanding that a system efficiency loss would occur due to the absence of the economizer. In this case, at conditions of 0° F. outdoor ambient and 70° F. indoor heated space temperature, the heating coefficient of performance (C.O.P.) will be at least 1.5 and may approach 2. By way of example, the displacement ratio of booster compressor 22 to primary compressor 24 could be increased to about 1.4:1 to about 1.7:1. Referring to FIGS. 6 and 7, with the economizer eliminated, the 211 line would be eliminated, and the 211 line is replaced by a 220 line, with the allowance point being the outdoor ambient temperature at which the 221 line was previously allowed, i.e., between about 15° F.-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com