Method and apparatus for inspecting pipelines from an in-line inspection vehicle using magnetostrictive probes

a magnetostrictive probe and pipeline technology, applied in the direction of instruments, diagnostic recording/measure, specific gravity measurement, etc., can solve the problems of heavy weight, difficult to handle, and limited internal access to the pipe wall that cannot be interrupted,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

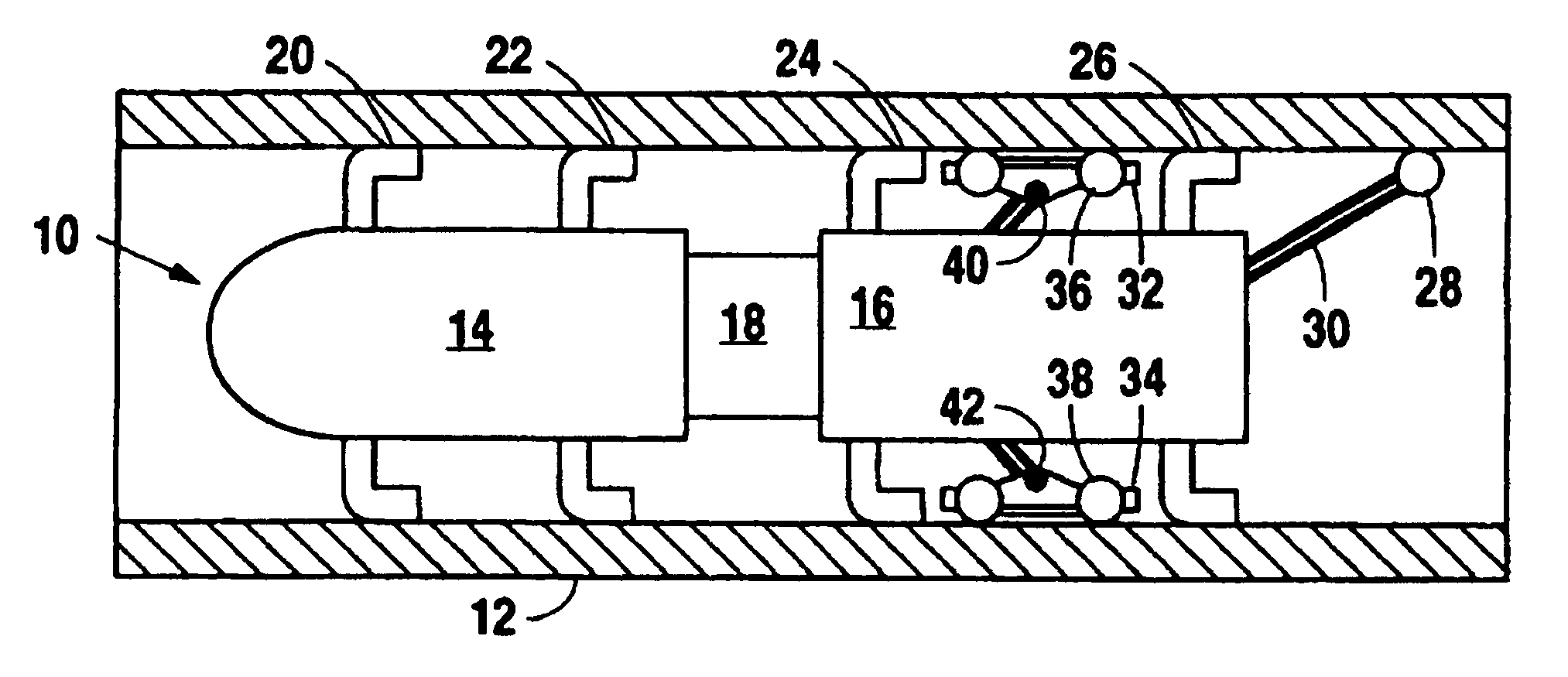

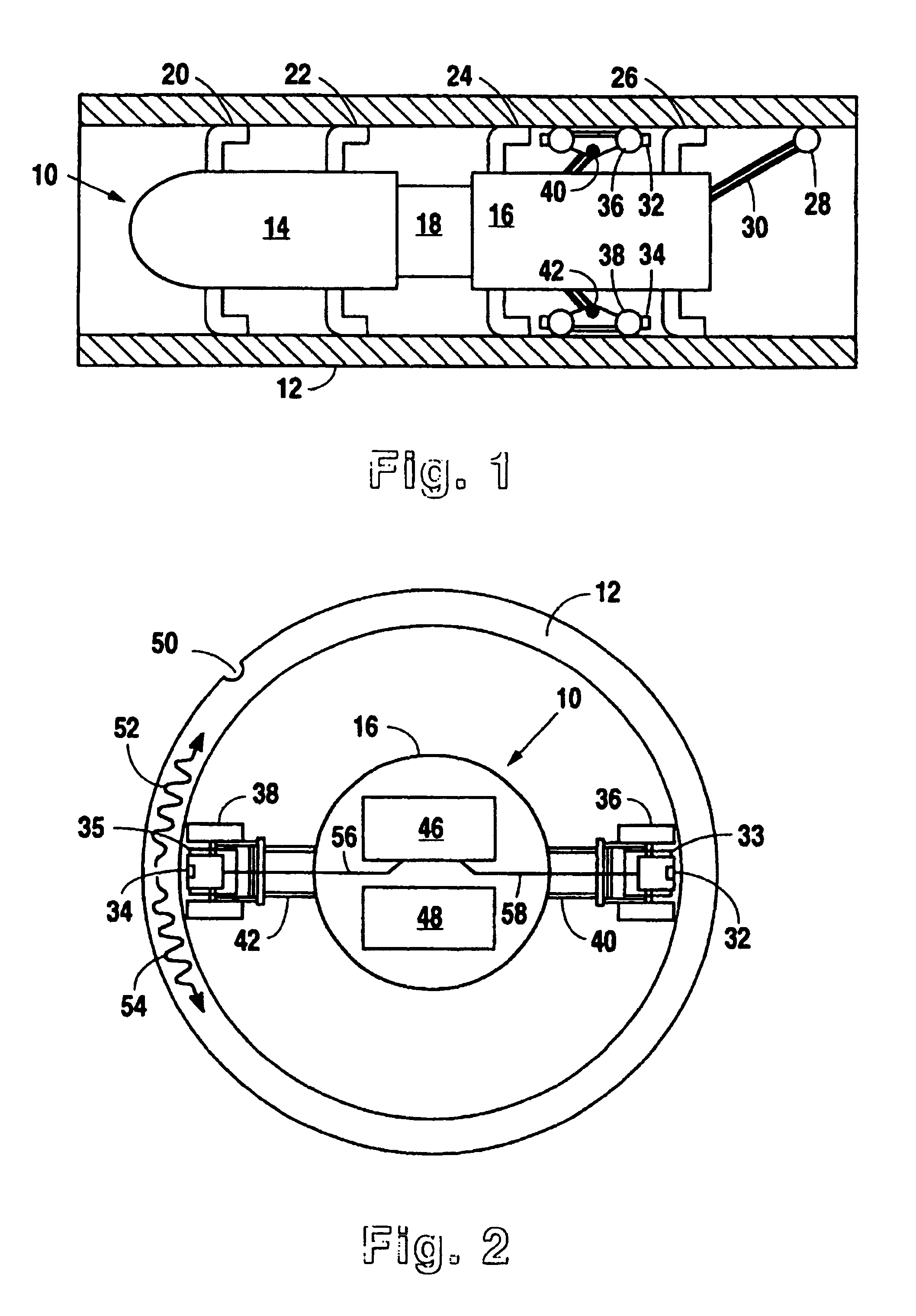

[0039]Reference is made first to FIG. 1 for a description of the structure of a preferred embodiment of the present invention shown in longitudinal cross section and positioned within a typical gas pipeline. In FIG. 1, pipeline wall 12 may be any of a number of standard sized gas pipelines, an example of which might be a 24 inch outside diameter, 0.562 inch thick pipe wall. In-line inspection vehicle 10 is comprised primarily of battery section 14 and sensor / instrument section 16. Sections 14 and 16 are connected together by a flexible coupling 18 which provides the necessary power connections between the sections and permits movement of in-line inspection vehicle 10 through bends and curves in pipeline 12.

[0040]In-line inspection vehicle 10 is propelled down the length of pipeline 12 by the pressurized gas carried through the pipeline. This propulsion is accomplished by use of a number of flexible cups 20, 22, 24 and 26 that are positioned in spaced arrangement on battery section 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distances | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com