Automobile paint film-protective sheet

a technology for protecting sheets and paints, applied in the direction of film/foil adhesives, synthetic resin layered products, transportation and packaging, etc., can solve the problems of high labor intensity, environmental problems, and defective above-surface protection sheets, and achieve excellent two basic protection properties, good balance, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

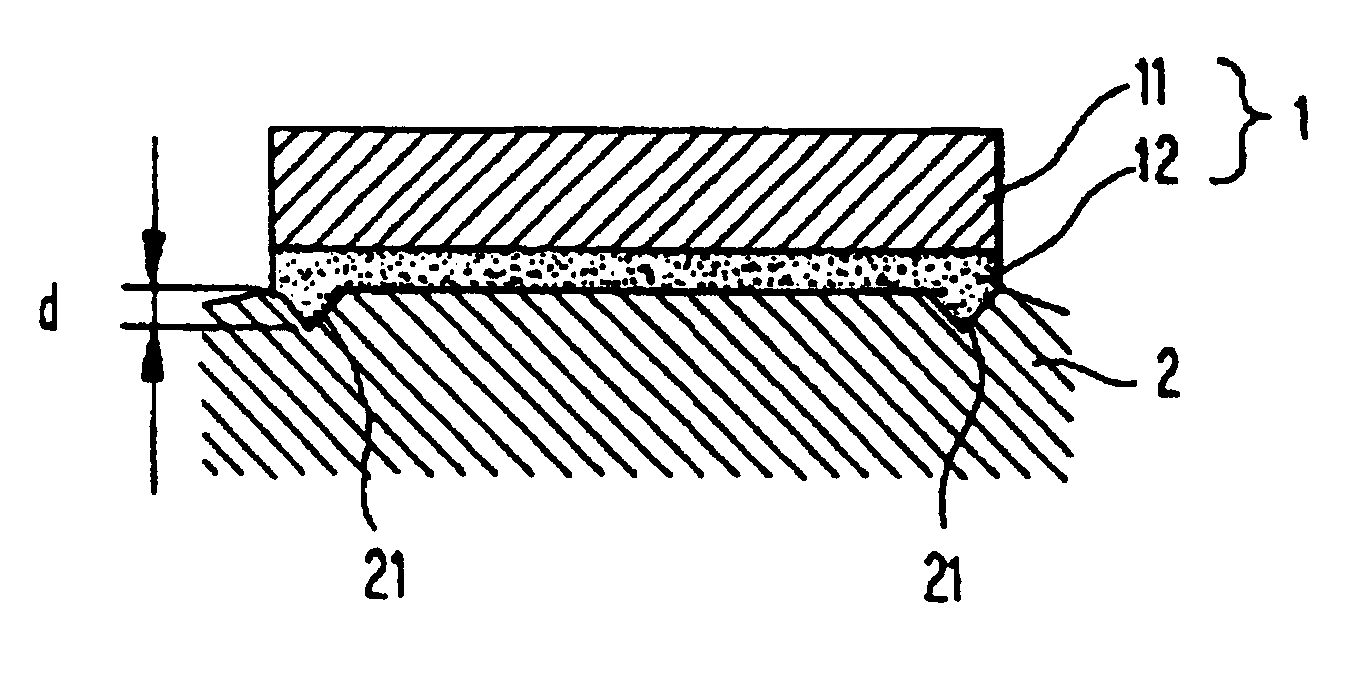

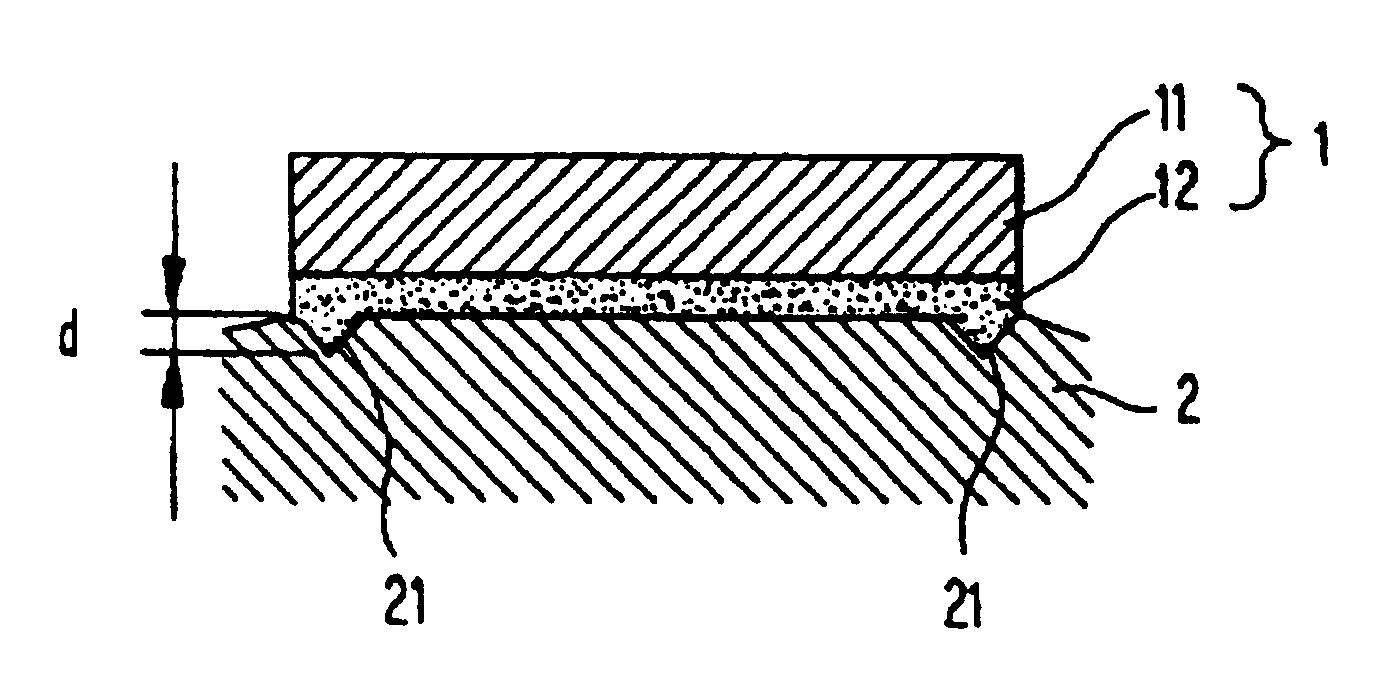

[0030]A toluene solution of a rubber-based pressure-sensitive adhesive comprising a mixture of 50 parts of a polyisobutylene having a viscosity-average molecular weight of 1,200,000 and 50 parts of a polyisobutylene having a viscosity-average molecular weight of 35,000 was coated on a 40 μm-thick film made of a polypropylene / polyethylene blend (weight ratio; 1 / 9), and then dried at 120° C. for 3 minutes, thereby obtaining a protective sheet having a pressure-sensitive adhesive layer having a dynamic modulus of 1.2×106 dyne / cm2 at 60° C. and a thickness of 10 μm. The dynamic modulus was determined by a measurement with a Vibron tester at a frequency of 1 Hz (hereinafter the same).

example 2

[0031]A protective sheet was obtained in the same manner as in Example 1 except that a rubber-based pressure-sensitive adhesive comprising a mixture of 25 parts of a polyisobutylene having a viscosity-average molecular weight of 1,200,000 and 75 parts of a polyisobutylene having a viscosity-average molecular weight of 35,000 was used to form a pressure-sensitive adhesive layer having a dynamic modulus of 4×105 dyne / cm2 at 60° C.

example 3

[0032]A protective sheet was obtained in the same manner as in Example 1 except that a rubber-based pressure-sensitive adhesive consisting of only a polyisobutylene having a viscosity-average molecular weight of 1,200,000 was used to form a pressure-sensitive adhesive layer having a dynamic modulus of 3×106 dyne / cm2 at 60° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com