Method for adjusting drive roller linefeed distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

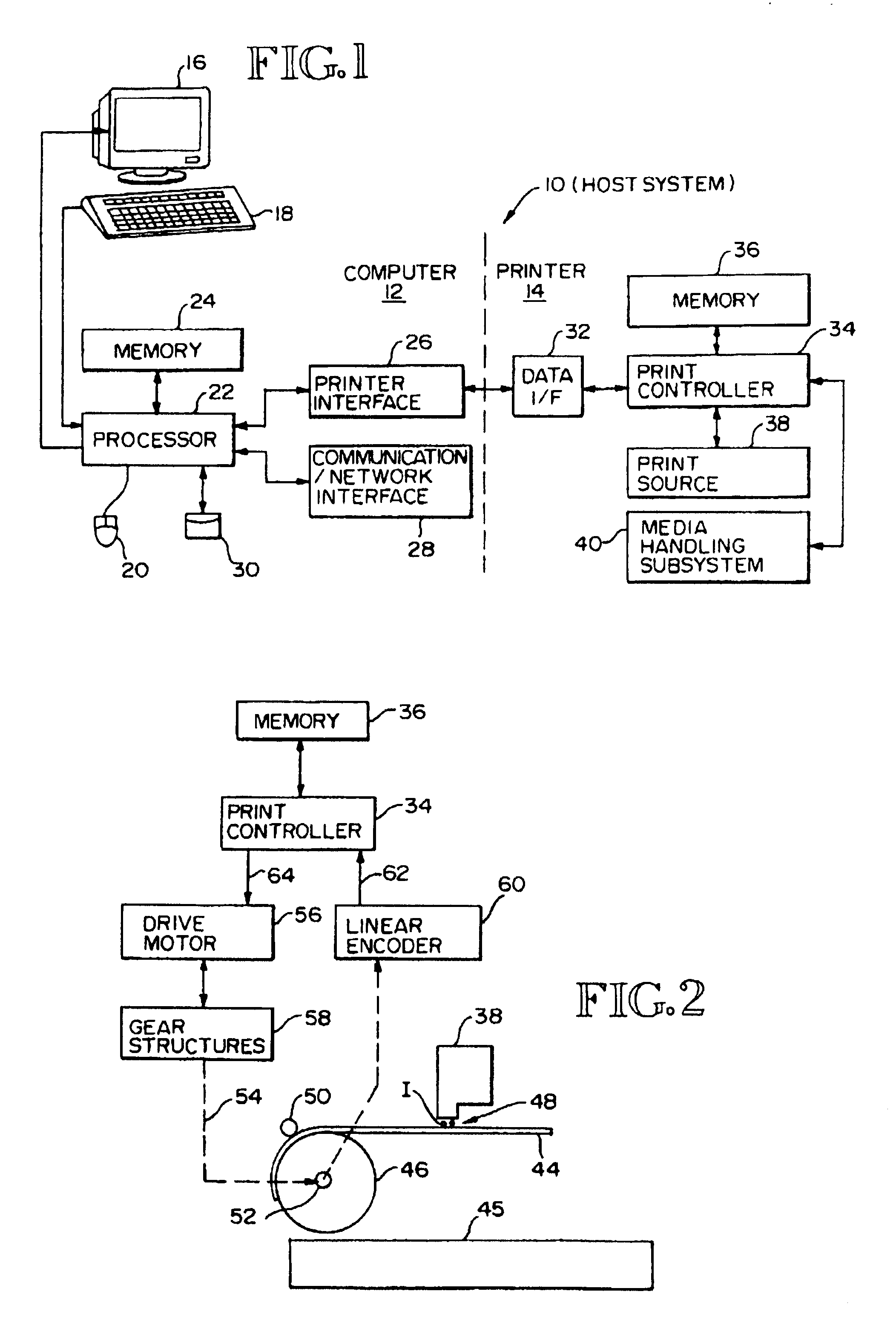

Host Environment

[0021]As used herein the term computer includes any device or machine capable of accepting data, applying prescribed processes to the data, and supplying results of the processes. FIG. 1 shows a host system 10, including a computer system 12 of the kind well known in the art, along with a printer 14. The host system 10 is configured to implement the method and apparatus of this invention. The computer system 12 includes a display monitor 16, a keyboard 18, a pointing / clicking device 20, a processor 22, memory 24, a printer interface 26, a communication or network interface 28 (e.g., modem; ethernet adapter), and a non-volatile storage device 30, such as a hard disk drive, floppy disk drive and / or CD-ROM drive. The memory 24 includes storage area for the storage of application program code, operating system code, and data. The processor 22 is coupled to the display 16, the memory 24, the keyboard 18, the point / clicking device 20, the printer interface 26, the communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com