Process control system including automatic sensing and automatic configuration of devices

a technology of automatic sensing and automatic configuration, applied in the field of process control systems, can solve the problems of extended downtime, time-consuming and inefficient individual programming of field devices, and inconvenient use of individual programming devices, so as to facilitate the configuration of a control system, reduce system management costs, and facilitate conformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

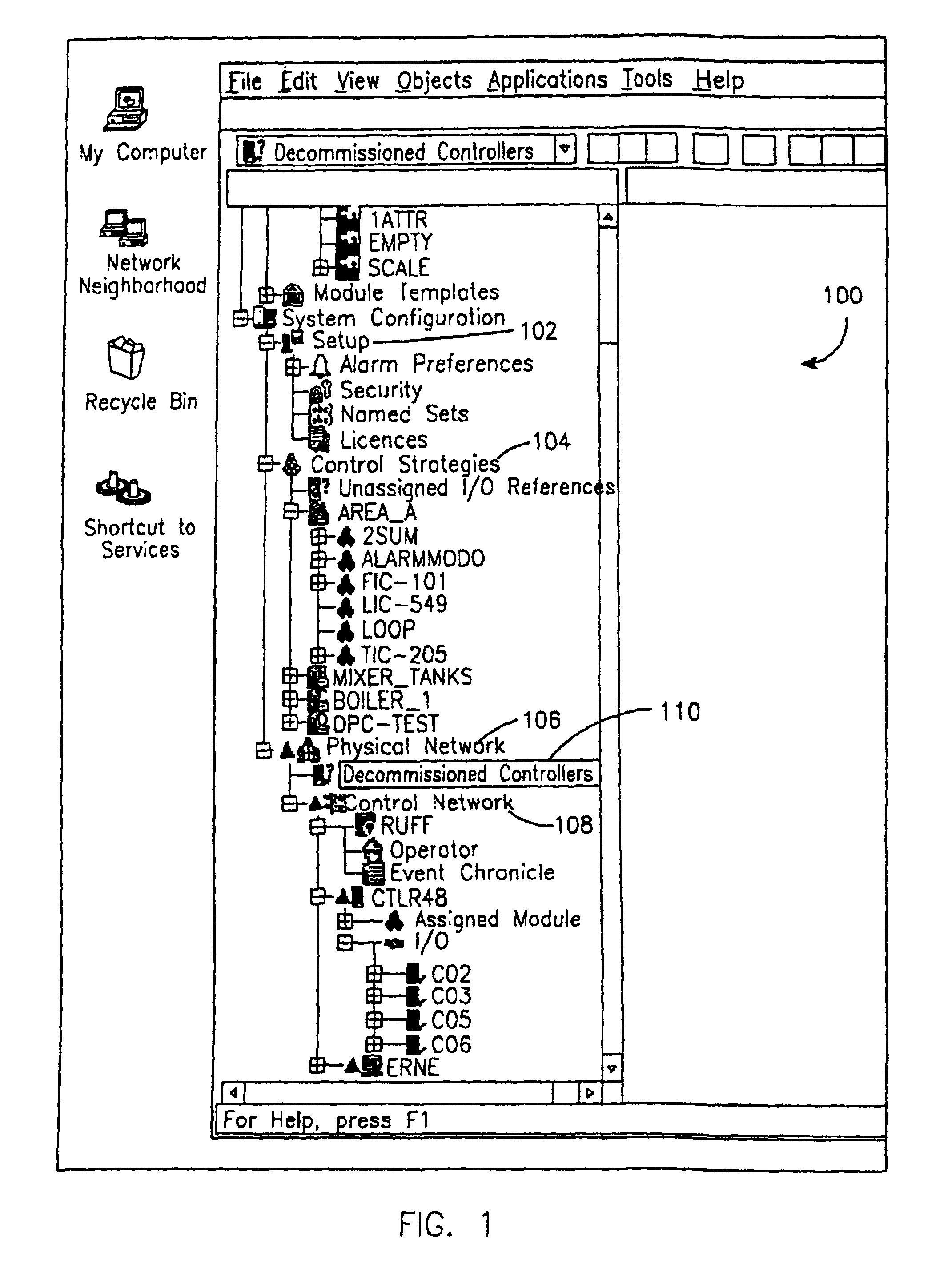

[0046]Referring to FIG. 1, a front-of-screen display, also called a “screen”100, for a graphical user interface (GUI) depicts a display of a system configuration. The screen 100 depicts navigation selections which are operated by a user to select, construct and operate a process control configuration. The navigation program supplies an initial state for navigating across various tools and processors in a network. A user controls the navigation program to access libraries, areas, process control equipment and security operations.

[0047]The illustrative system configuration is described and controlled with respect to a control system setup 102, control strategies 104, and a physical setup 106. The functions of automatically sensing and automatically configuring a control system relate to the physical setup 106. In particular, the functions of automatically sensing and automatically configuring physical devices in a control system relate to the commission and activation of devices in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com