Web member for concrete form walls

a technology of concrete form walls and web members, applied in the field of web members for concrete form walls, to achieve the effects of enhancing strength, reducing material, and strengthening and reinforcing grids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

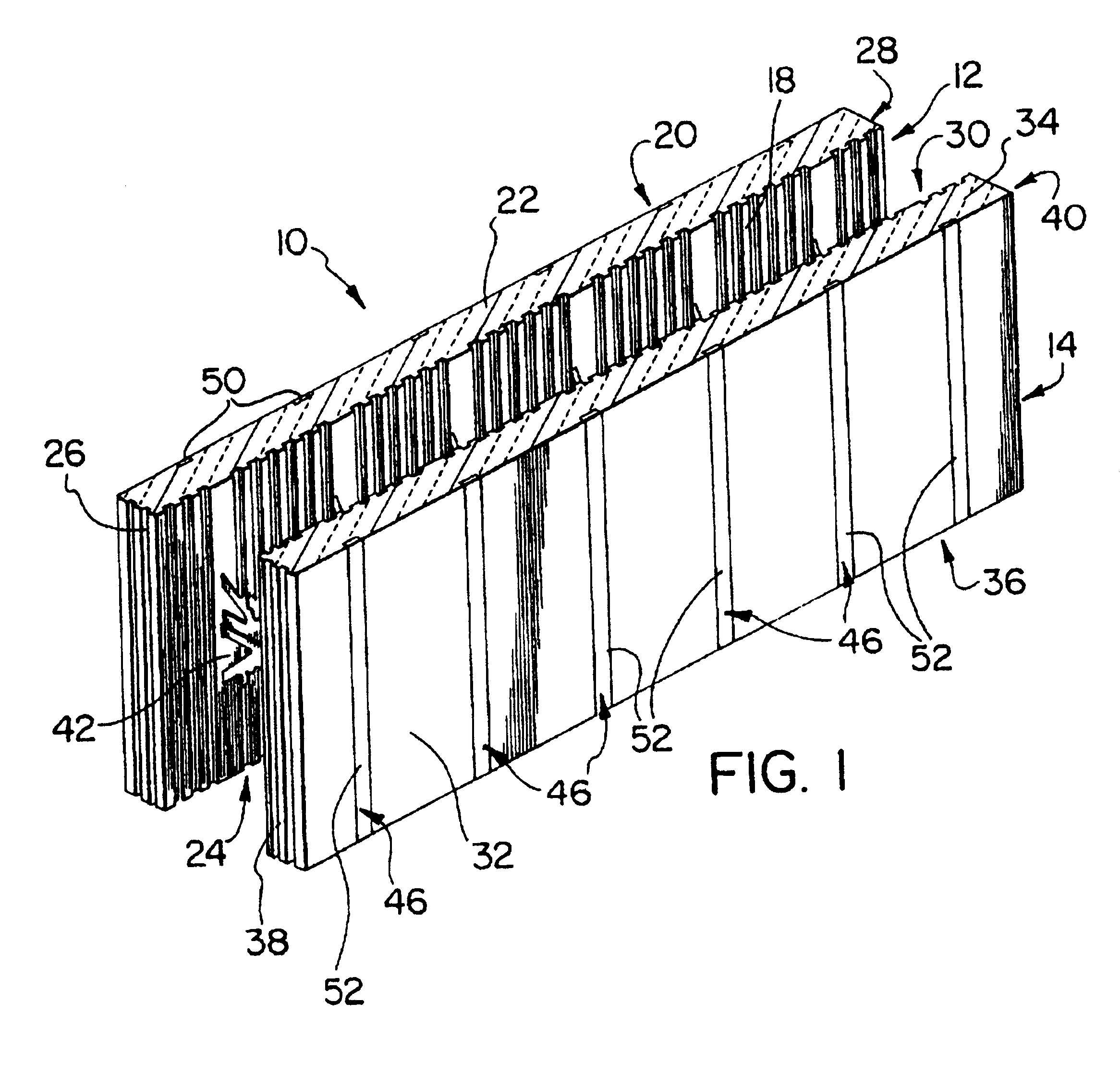

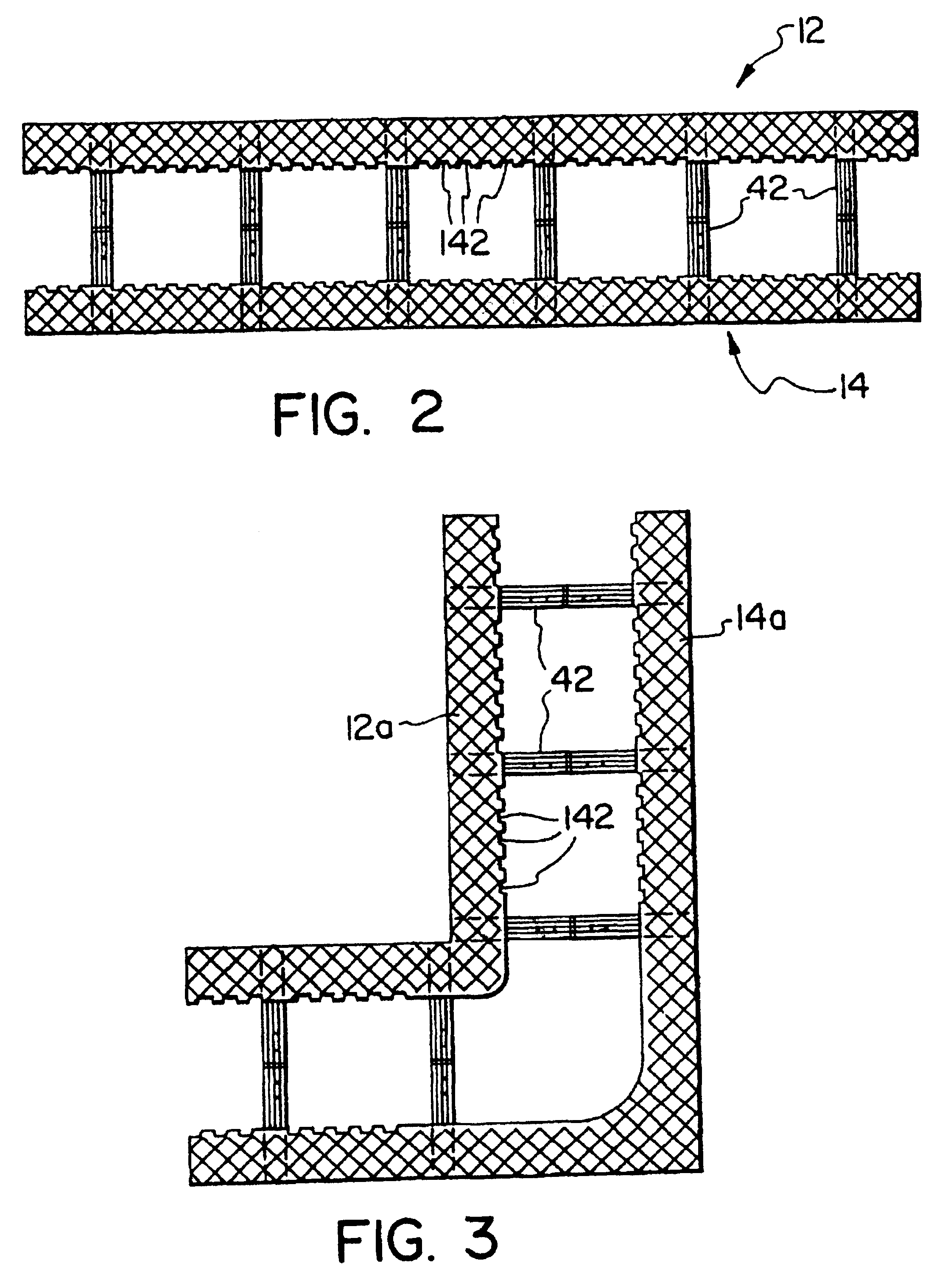

[0042]The building component 10 comprises first and second foam panels 12 and 14 secured together by at least two bridging members 42.

[0043]Panel 12 comprises inner and outer surfaces 18 and 20 respectively, top and bottom 22 and 24 respectively, and first and second ends 26 and 28. Panel 14 comprises inner and outer surfaces 30 and 32, top and bottom 34 and 36, and first and second ends 38 and 40.

[0044]The panels 12 and 14 are preferably fire retardant expanded polystyrene, polyethylene or polypropylene. Subject to indentations and protrusions of minor height to be discussed below, the panels are of uniform rectangular cross-section. In a typical case each panel may be 48 inches long, 16¾ inches high and 2⅝ inches thick.

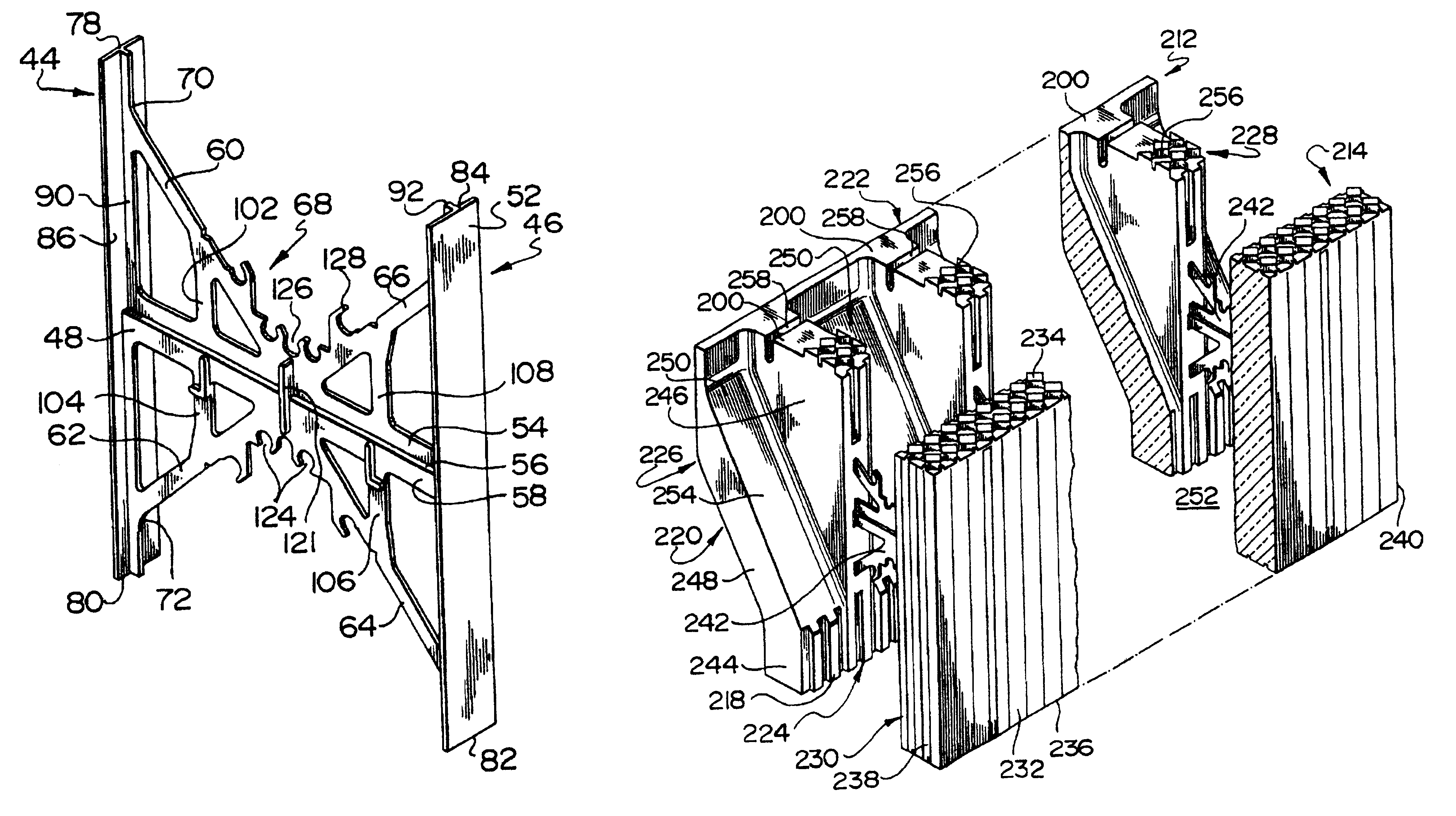

[0045]Bridging members 42 comprise a pair of elongated end plates 44 and 46 joined by narrow strip member 48.

[0046]As illustrated, for example, in FIG. 1, the end plates 44 and 46 have their outer surfaces 50 and 52 respectively substantially flush with the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com