Voltage reactive power integrated control device based on magnetic control reactor

A magnetically controlled reactor and comprehensive control technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as not involving comprehensive control, unfavorable installation and use, and large footprint, and achieve harmonic The effect of small current, lower overall cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

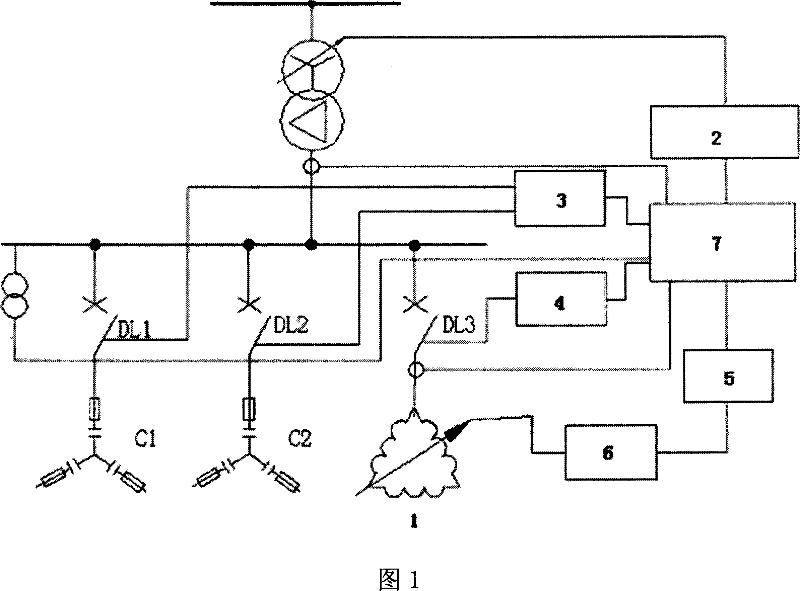

[0036] As shown in Figure 1, the present invention includes: a three-phase six-column epoxy cast dry-type magnetron reactor (MCR) 1, a main transformer on-load tap changer control module 2, a capacitor switching module 3, and a reactor protection module 4 , a pulse electro-optic conversion circuit 5, a trigger control module 6 and an intelligent control module 7. The connection relationship is: the three-phase six-column epoxy cast dry-type magnetic control reactor MCR1 (hereinafter referred to as the magnetic control reactor 1) and the capacitor bank are connected in parallel to the busbar on the low-voltage side of the transformer, and the main transformer on-load tap-changer control module 2 is connected to The main transformer on-load tap-changer is used to control the upshift or downshift of the on-load tap-changer gear. The trigger control module 6 is connected to the three-phase six-column epoxy cast dry-type magnetron reactor MCR1 to control the output capacity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com