Infrared metal honeycomb burner used on gas burning range and its producing method

A technology of metal honeycomb and gas appliances, which is applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve problems that cannot be fundamentally solved, low thermal efficiency, and difficulty in process standardization, so as to eliminate poor sealing, high standardization, and Adapt to the effect of a wide range of air sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with several preferred embodiments and accompanying drawings thereof,

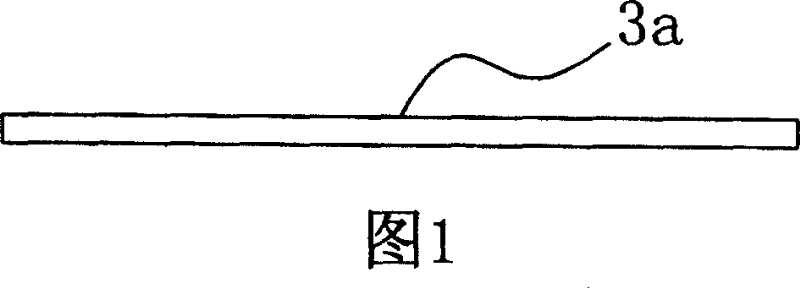

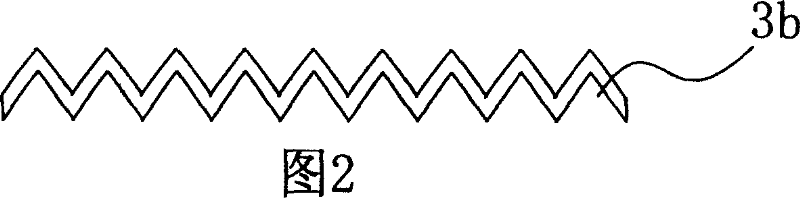

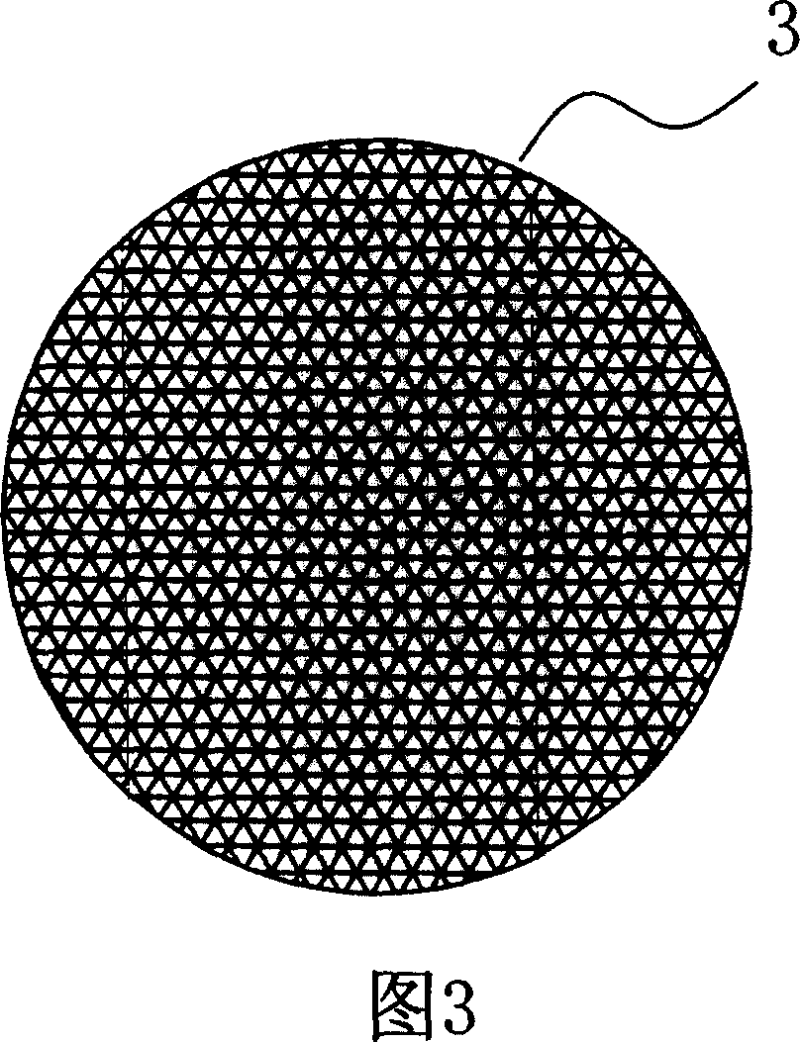

[0023] See accompanying drawing 1~accompanying drawing 3, this implementation method is to make the air mixing chamber of the burner into one or more independent air mixing chamber air outlets or make multiple air outlets on an independent air outlet. Relatively independent air outlets are designed with double or multi-layer metal sheets as metal sheets 3a or corrugated metal sheets 3b as shown in accompanying drawings 1 and 2, and then they are superimposed, welded or wound. Form the metal honeycomb body 3 with infrared radiation function for burners of various shapes, and connect the outer wall of the metal honeycomb body 3 with the inner diameter side wall of the gas outlet of the gas mixture chamber of the burner, so that it can be formed independently One combustion surface or multiple independent combustion surfaces or multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com