Connection structure of gas container

A technology of gas container and structure, which is applied in the direction of grounding device, switchgear with metal casing, busbar/line layout, etc., can solve the problems of gas container loss of airtightness, rupture or shrinkage, etc., and achieve the purpose of suppressing thermal deformation and Effects of residual stress, reduction of cracking or shrinkage, reduction of labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

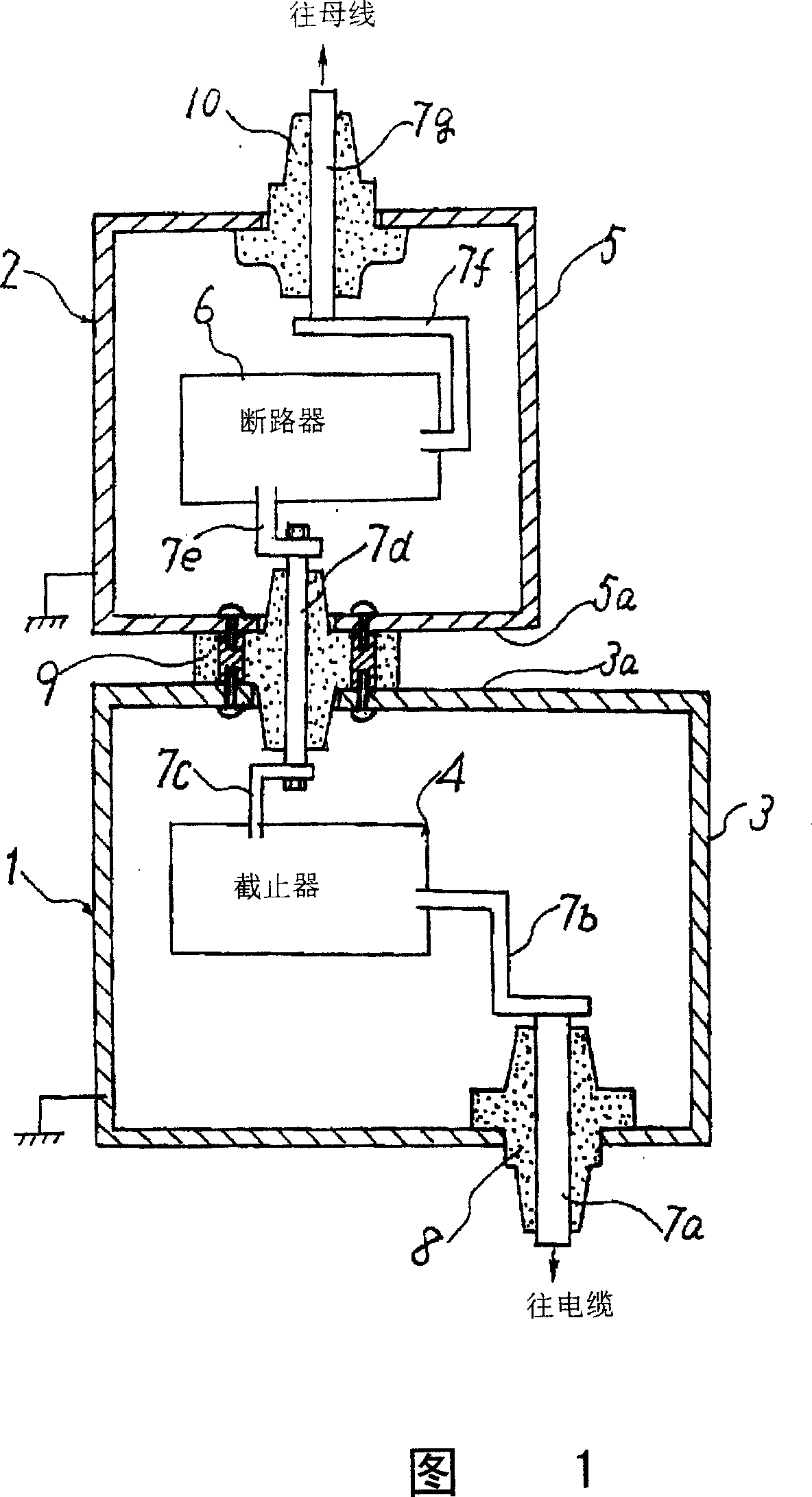

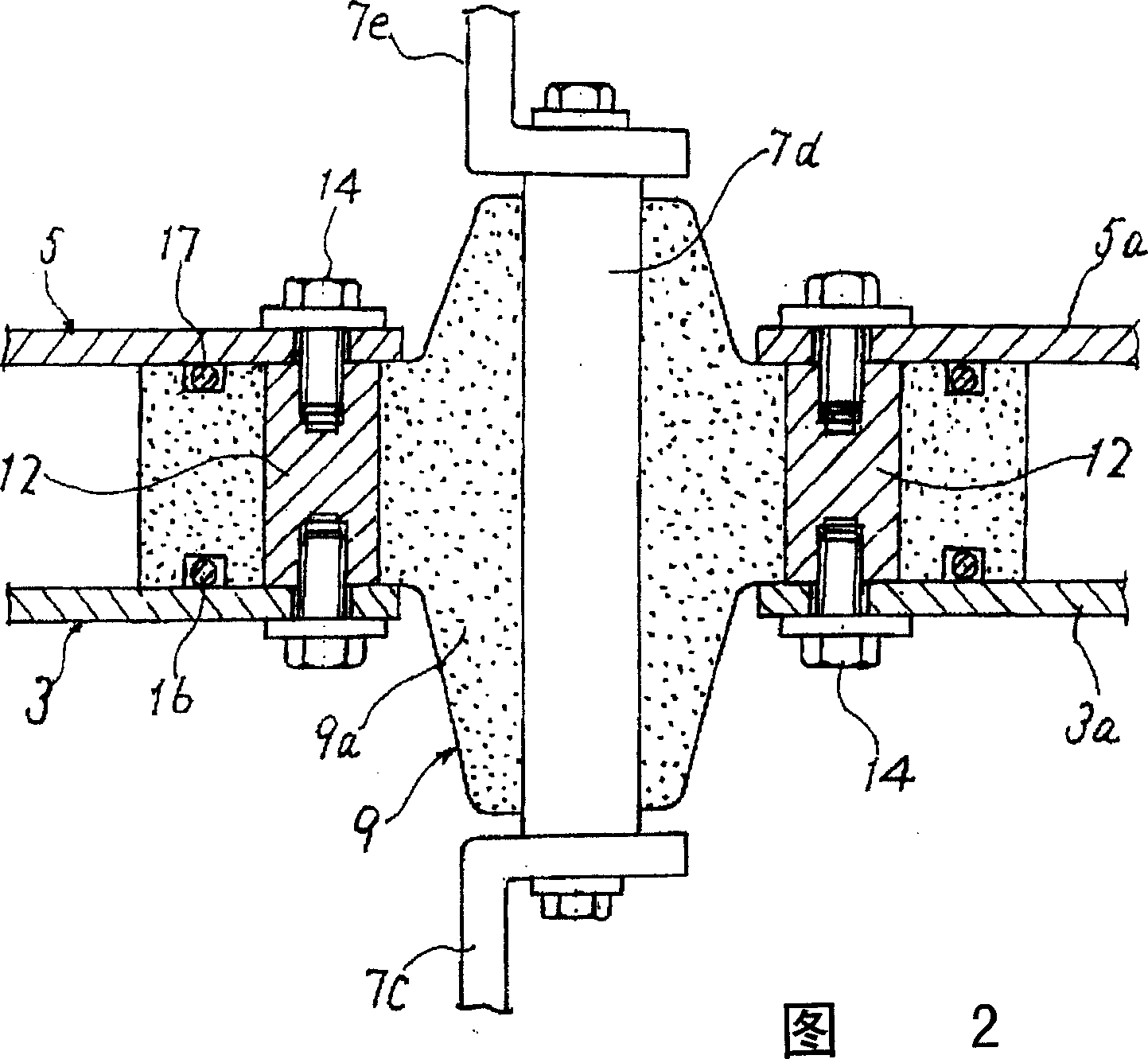

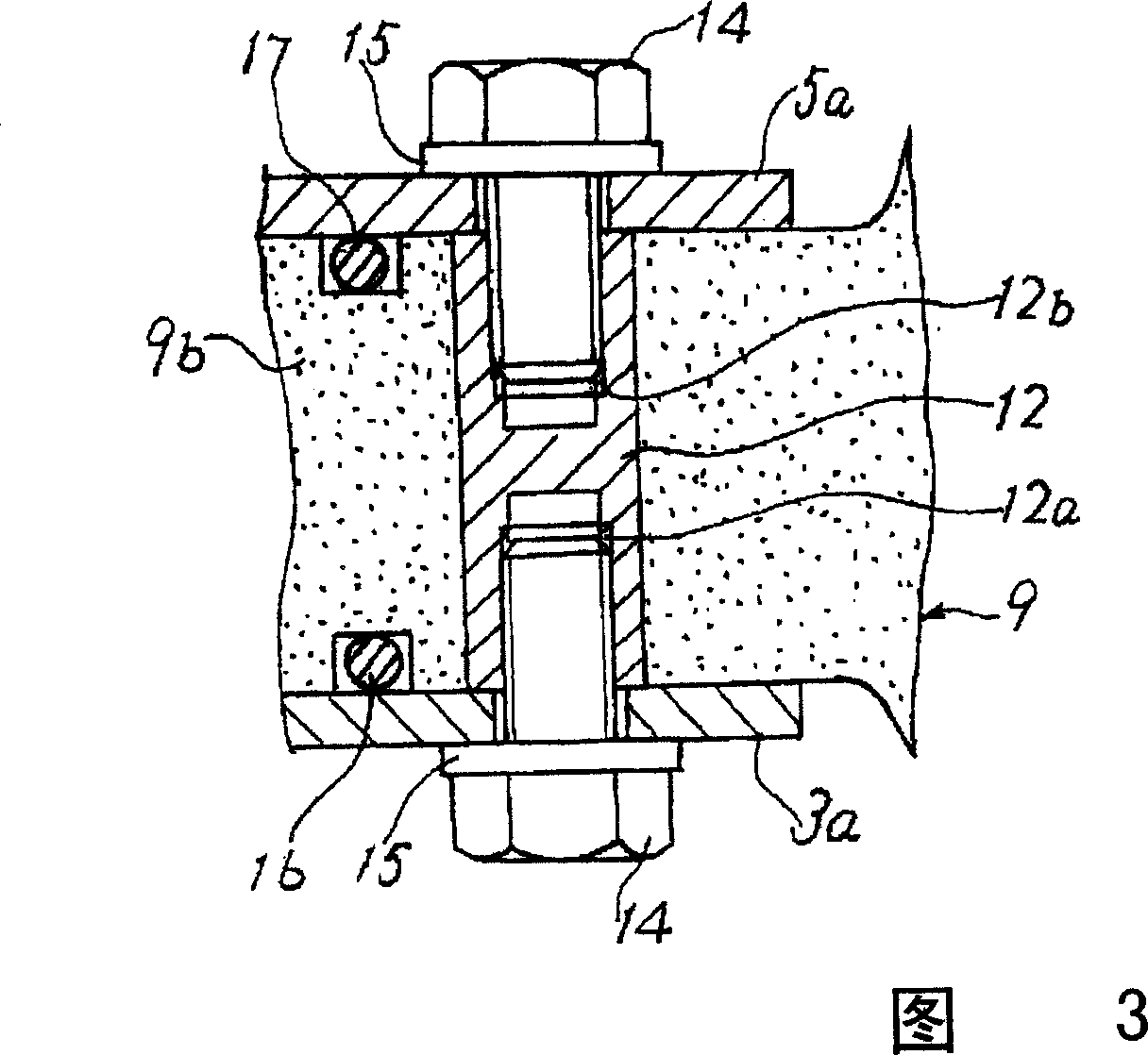

[0020] 1 is a sectional view of a gas insulated switchgear showing a switchgear according to Embodiment 1 of the present invention. FIG. 2 is an enlarged sectional view showing a connection portion of two equipment units constituting the gas insulated switchgear of FIG. 1 , and FIG. 3 It is a cross-sectional view showing only the part where the partition walls of the two gas containers are fixed to the liner in FIG. 2 .

[0021] The gas insulated switchgear of the switchgear according to the first embodiment includes two equipment units 1 and 2 . Furthermore, in one equipment unit 1 , the stopper 4 is accommodated inside the gas container 3 , and in the other equipment unit 2 , the circuit breaker 6 is accommodated inside the gas container 5 . In addition, in each gas container 3, 5, in order to improve the withstand voltage performance of each device 4, 6, for example, an insulating gas such as SF6 gas is sealed.

[0022] In addition, the circuit conductors 7a to 7g are sequ...

Embodiment 2

[0028] Fig. 4 is a cross-sectional view showing only the parts where the partition walls of the two gas containers are fixed to the bushings in Embodiment 2 of the present invention are taken out and shown. For the constituent parts corresponding to Embodiment 1 shown in Figs. 1 to 3, same number.

[0029] The second embodiment is characterized in that the female screw parts 13a, 13b formed from both end surfaces of the embedded metal fitting 13 embedded in the flange part 9b of the bushing 9 and facing inward are not in a state of facing each other, but The positions are shifted from each other in the direction perpendicular to the thickness direction of the embedded metal 13 . The other configurations are the same as those in Embodiment 1, and thus detailed description thereof will be omitted here.

[0030] In the structure of the present embodiment 2, since the thickness of the flange portion 9b of the bushing 9 can be made thinner, in addition to obtaining the functions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com