Conjugation method for resin molding product

A resin molding and joining method technology, which is applied in the joining field of resin molded products, can solve problems such as unstable creep failure life, achieve the effects of preventing defects such as residual voids, stable creep failure life, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

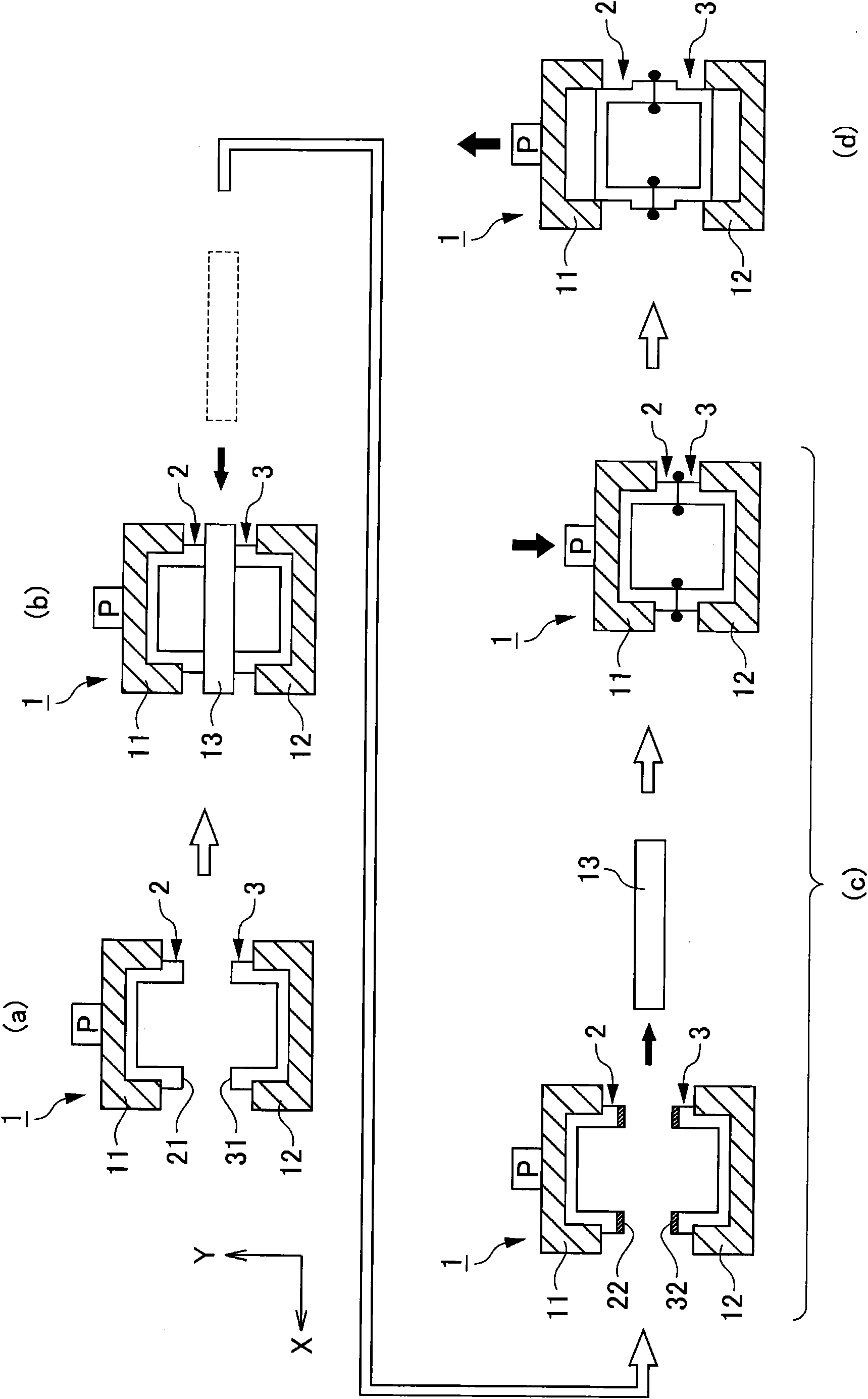

[0096] Joining preparation process

[0097] Using polyacetal ("DURACONM90-44" manufactured by Polyplastics Co., Ltd.) as the resin material, injection molding was performed under the following molding conditions to produce Figure 4 The resin test piece shown in (a).

[0098] Molding conditions

[0099] Molding machine: ROBOSHOTα-50C (manufactured by FANUC LTD.)

[0100] Barrel temperature: (nozzle) 200°C-200°C-180°C-160°C (hopper)

[0101] Injection speed: 10mm / s

[0102] Holding pressure: 60MPa

[0103] Injection time + holding time: 15 seconds

[0104] Cooldown: 10 seconds

[0105] Screw speed: 100rpm

[0106] Screw back pressure: 4MPa

[0107] Mold temperature: 80°C

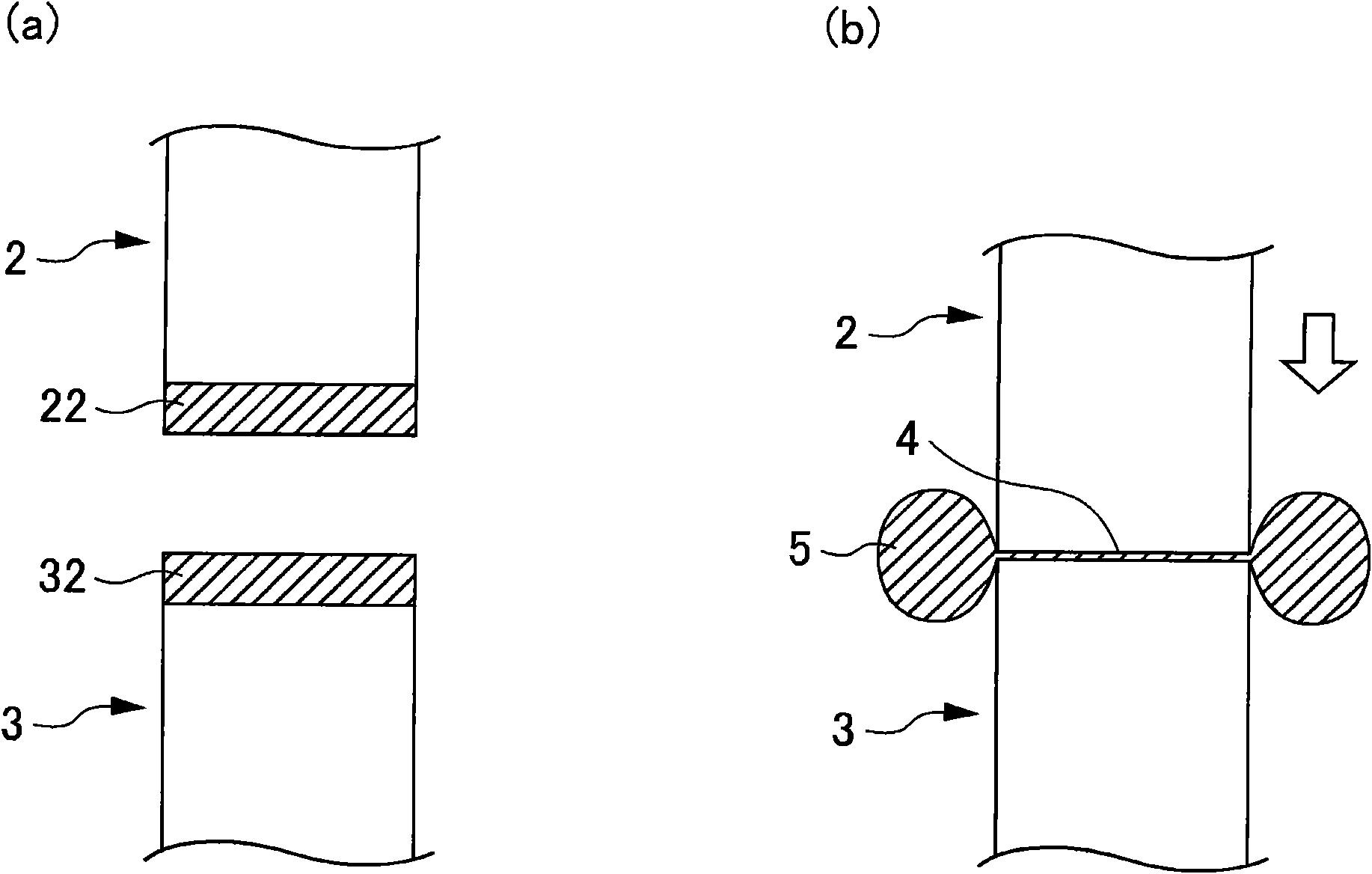

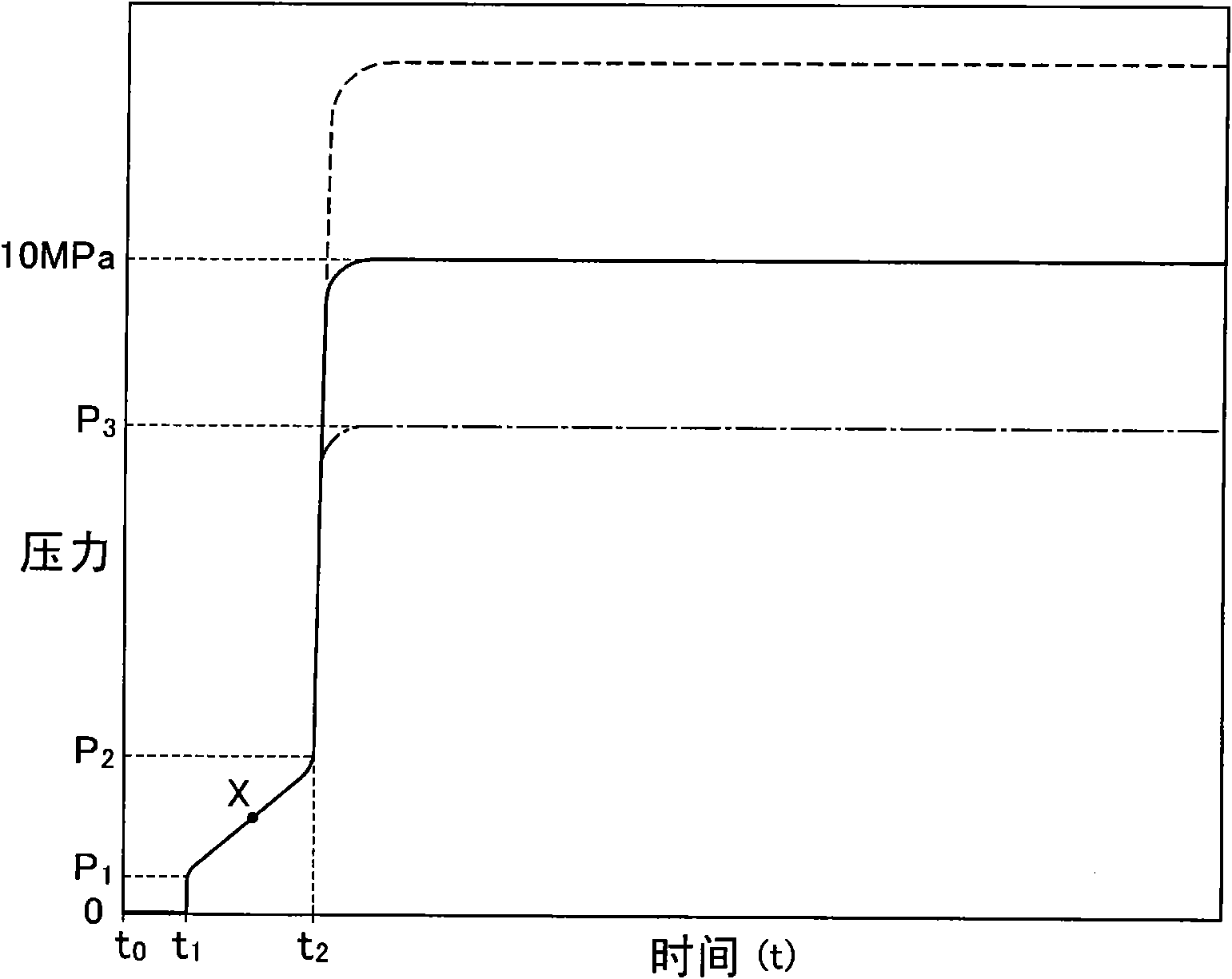

[0108] The above two resin test pieces were mounted on a hot plate welding device ("PW-1" manufactured by Nakamori Kogyo Co., Ltd.). The schematic diagram of the hot plate welding device is as follows: Figure 5 shown. also, Figure 5 It shows the hot plate welding device in the formation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com