Production of cotton ball from cotton sliver and cotton ball maker

A technology of cotton ball machines and cotton balls, applied in medical science, bandages, etc., can solve problems such as false adhesion of fiber clusters, and achieve the effects of uniform density, high roundness, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

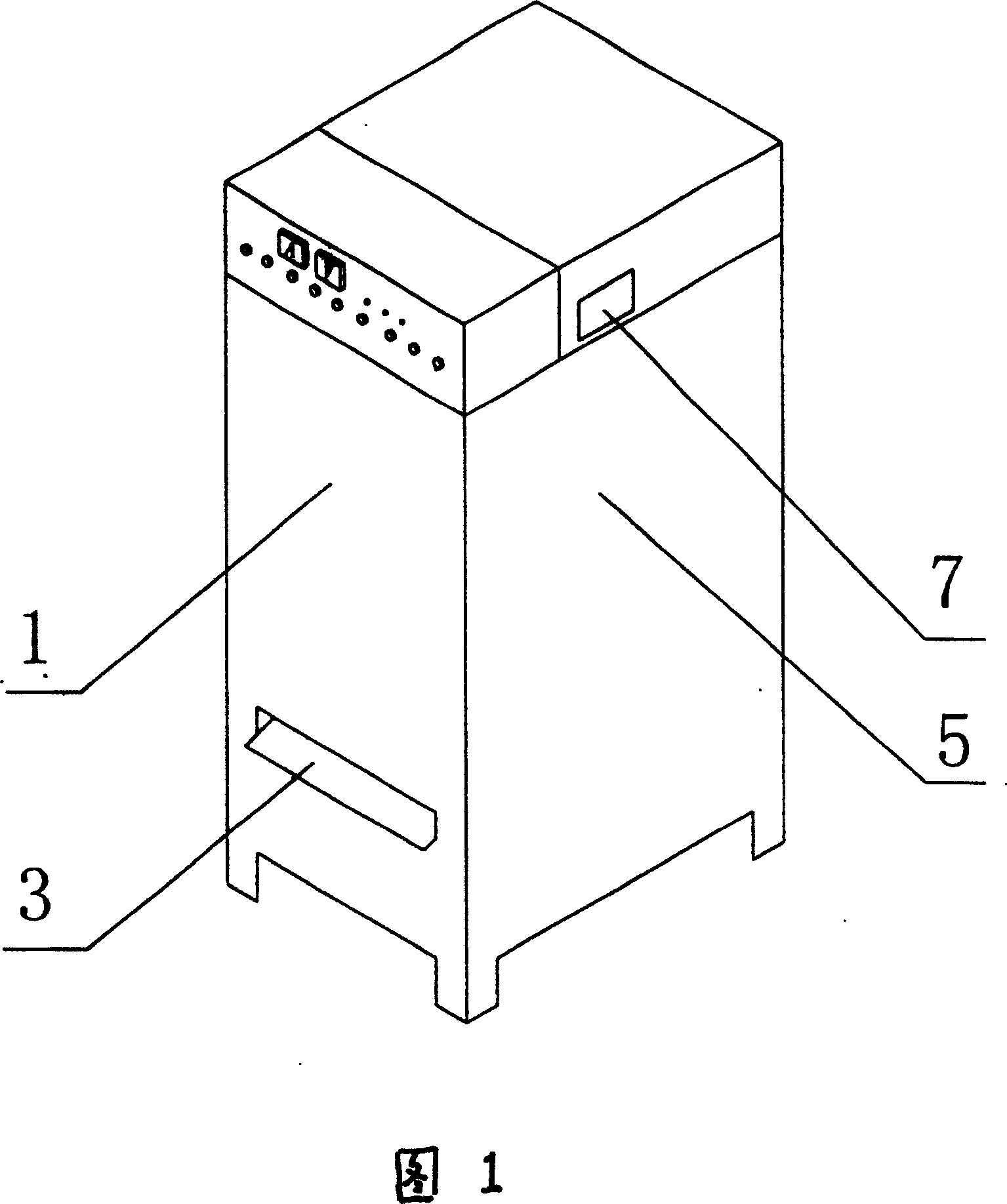

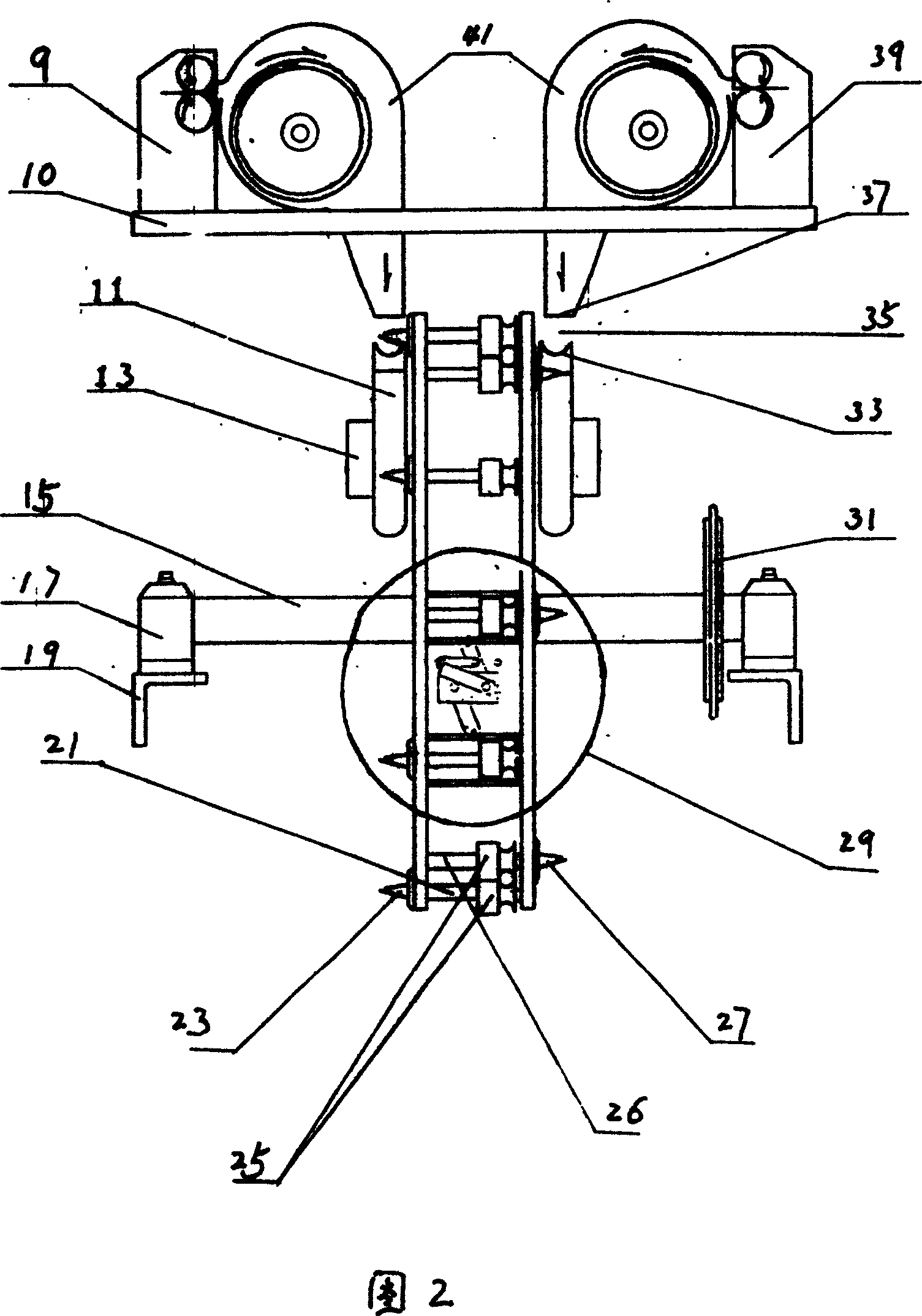

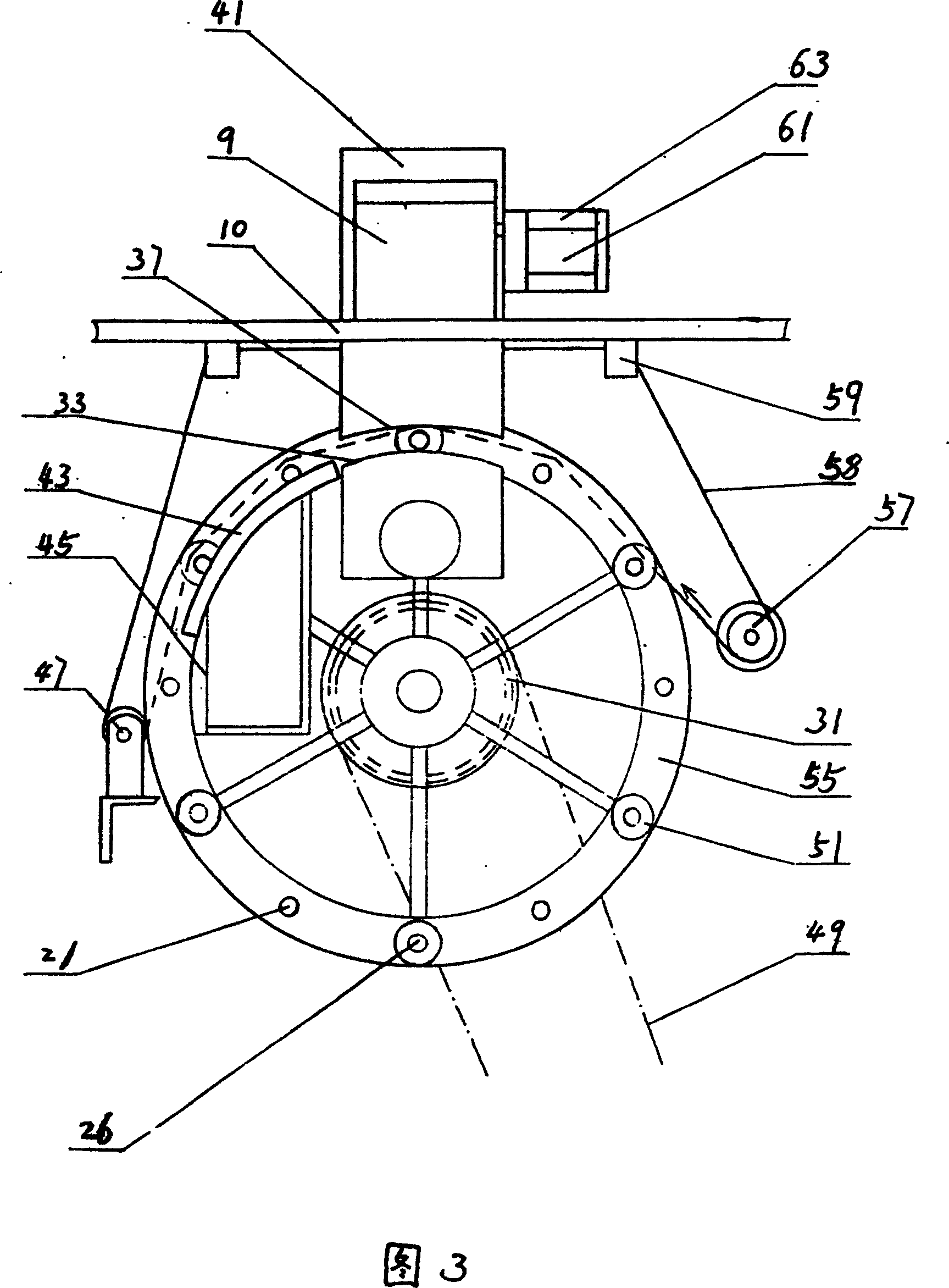

[0025]The present invention will be further described below (in conjunction with accompanying drawings). The invention relates to a method for producing cotton balls by using cotton slivers, the cotton feeding speed required by the cotton feeding process is determined by specific product specifications and determined according to the production of cotton ball machines per unit time. Because the cotton feeding mechanism (9 or 39) in the prior art mostly adopts the method in which the driving roller and the driven roller are engaged, the control of the amount of cotton feeding only needs to adjust the rotational speed of the driving wheel. The way of adjusting resistance can be adopted for this reason to realize the adjustment to the DC motor (61) rotating speed. The amount of cotton fed per unit time is a relatively important parameter in the cotton feeding process. Both too much and too little will cause excessive accumulation of cotton fibers in the cotton ball machine and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com