Wind power generation hydraulic coupling control system and control method thereof

A control system and hydraulic coupling technology, applied in wind turbine control, wind turbine combination, wind power generation, etc., can solve problems such as maintenance difficulties, unstable generator output voltage and frequency, and unfavorable generator grid-connected operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

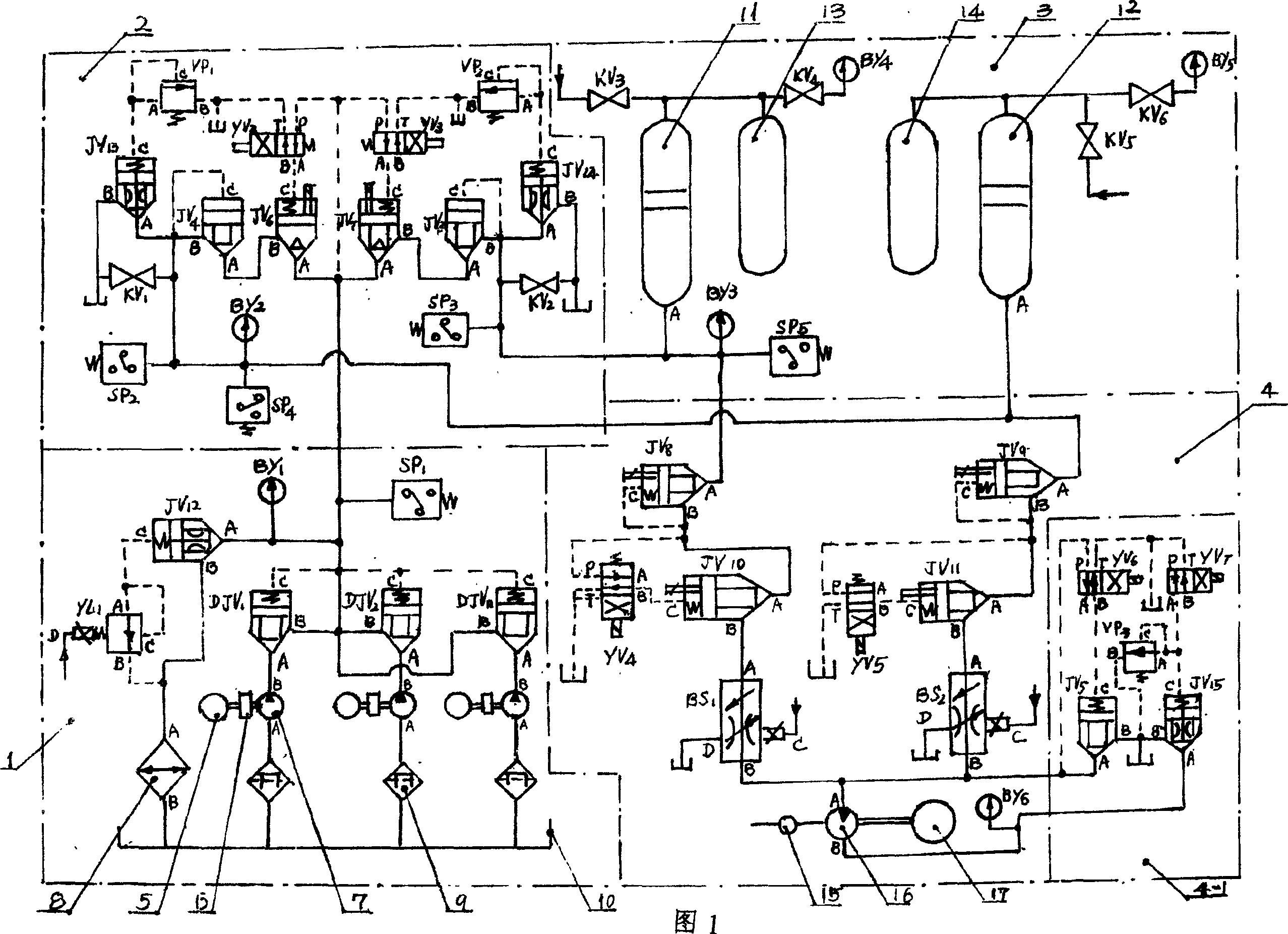

[0009] Referring to the accompanying drawings, a wind power generation hydraulic coupling control system mainly composed of three wind turbines 5, three gearboxes 6, and generator 17 is characterized in that it is between the shaft end of the gearbox 6 and the generator 17. There are hydraulic pump system 1, pressure limiting system 2, pressure compensating and stabilizing system 3, constant current and constant speed system 4 and braking system 4-1. Hydraulic pump system 1, which includes three plunger pumps 7, three filters with magnetic elements 9, three pumps with plug-in one-way poppet valve DJV 1 , DJV 2 , DJV n , Cartridge relief valve JV 12 , pressure switch SP 1 , pressure gauge By 1 , proportional relief valve YL 1 , cooler 8 and oil pool 10; the rotor of the hydraulic plunger pump 7 is fixedly connected to the shaft of the gearbox 6, and a filter 9 with a magnetic filter element is installed between the oil suction inlet of the hydraulic plunger pump 7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com