Lead free solder

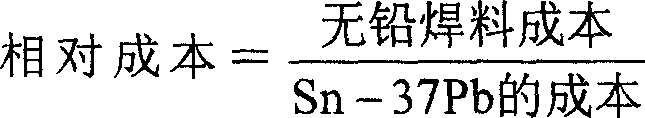

A lead-free solder and solder technology, used in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of low strength and plasticity, poor wettability, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put 30.0Kg of Sn and 20.0Kg of Bi into an alumina crucible, and put it into an intermediate frequency furnace for melting at a melting temperature of 400°C, keep it warm for 2 hours, fully stir it, take it out of the furnace, and cool it to make tin containing 40% bismuth Bismuth master alloy. Put 45.0Kg of Sn and 5.0Kg of Sb into an alumina crucible, and put it into an intermediate frequency furnace for melting at a melting temperature of 400°C, keep it warm for 2 hours, fully stir it, take it out of the furnace, and cool it to make tin with 10% antimony Antimony master alloy. Put 48.0Kg of Sn and 2.0Kg of Ce into an alumina crucible, and put it into a vacuum medium-frequency induction melting furnace for melting. The melting temperature is 1000°C, keep it warm for 2 hours, fully stir it, take it out of the furnace, and cool it to make a cerium-containing product. 4% tin-cerium master alloy.

[0034] Take 0.019Kg of the above-mentioned tin-bismuth master alloy, 0.035...

Embodiment 2

[0036] Get 0.019Kg of tin-bismuth master alloy of embodiment 1, 0.035Kg of tin-antimony master alloy, 0.063Kg of tin-cerium master alloy and 4.884Kg of pure tin, put into the melting in stainless steel pot, melting temperature is 550 ℃, and holding time is 1.5 hours, fully After being stirred, it is released from the furnace and cast on a steel welding rod mold to obtain lead-free solder rods.

Embodiment 3

[0038] Get embodiment 1 tin-bismuth master alloy 0.194Kg, tin-antimony master alloy 0.260Kg, tin-cerium master alloy 0.088Kg and pure tin 4.459Kg, put into the melting in the stainless steel pot, melting temperature is 550 ℃, and holding time is 1.5 hours, fully After being stirred, it is released from the furnace and cast on a steel welding rod mold to obtain lead-free solder rods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com