Fluid coupling

A technology of hydraulic couplings and drive shafts, applied in fluid transmission devices, components with teeth, belts/chains/gears, etc., to achieve the effects of avoiding slip, easy control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

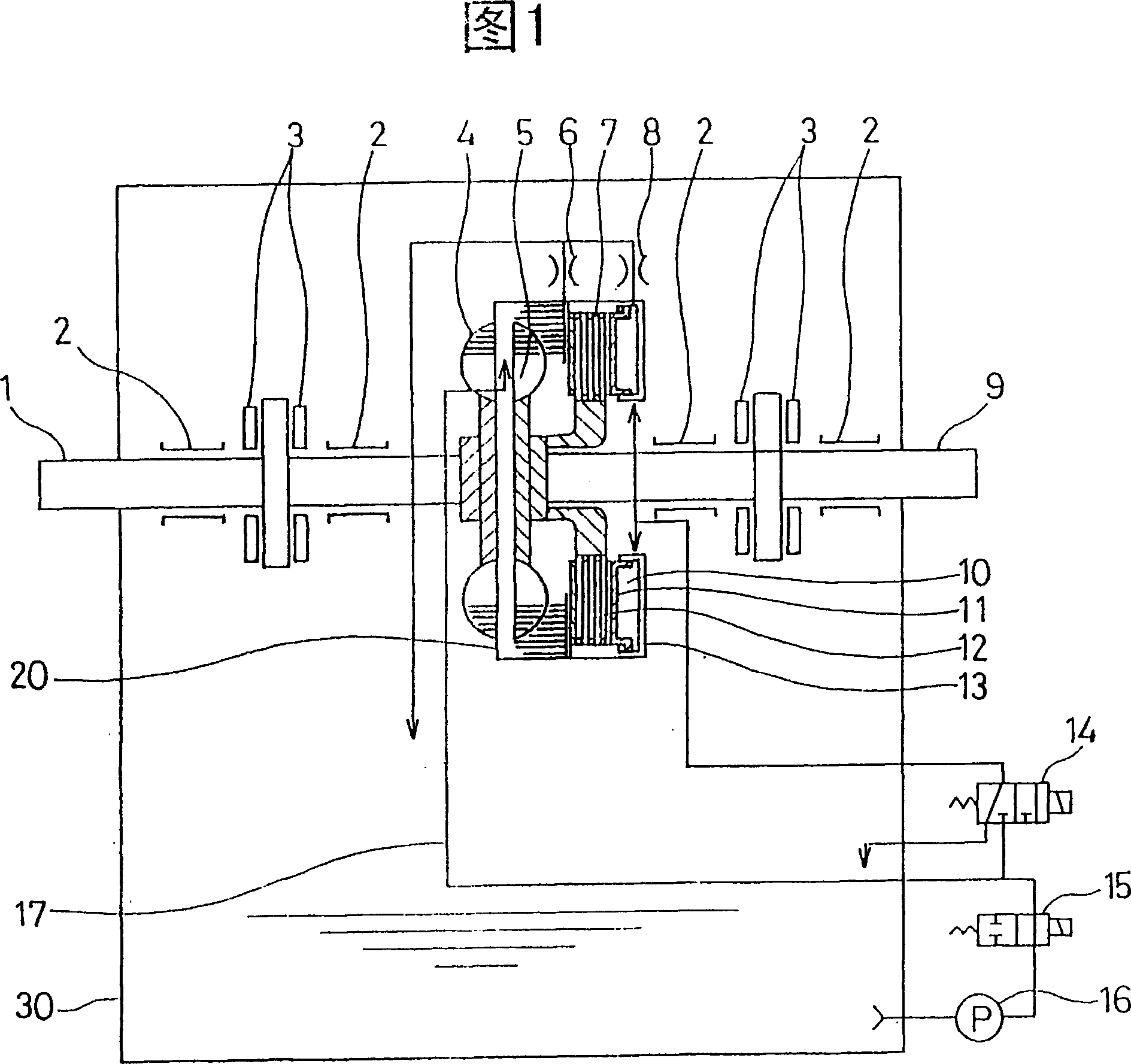

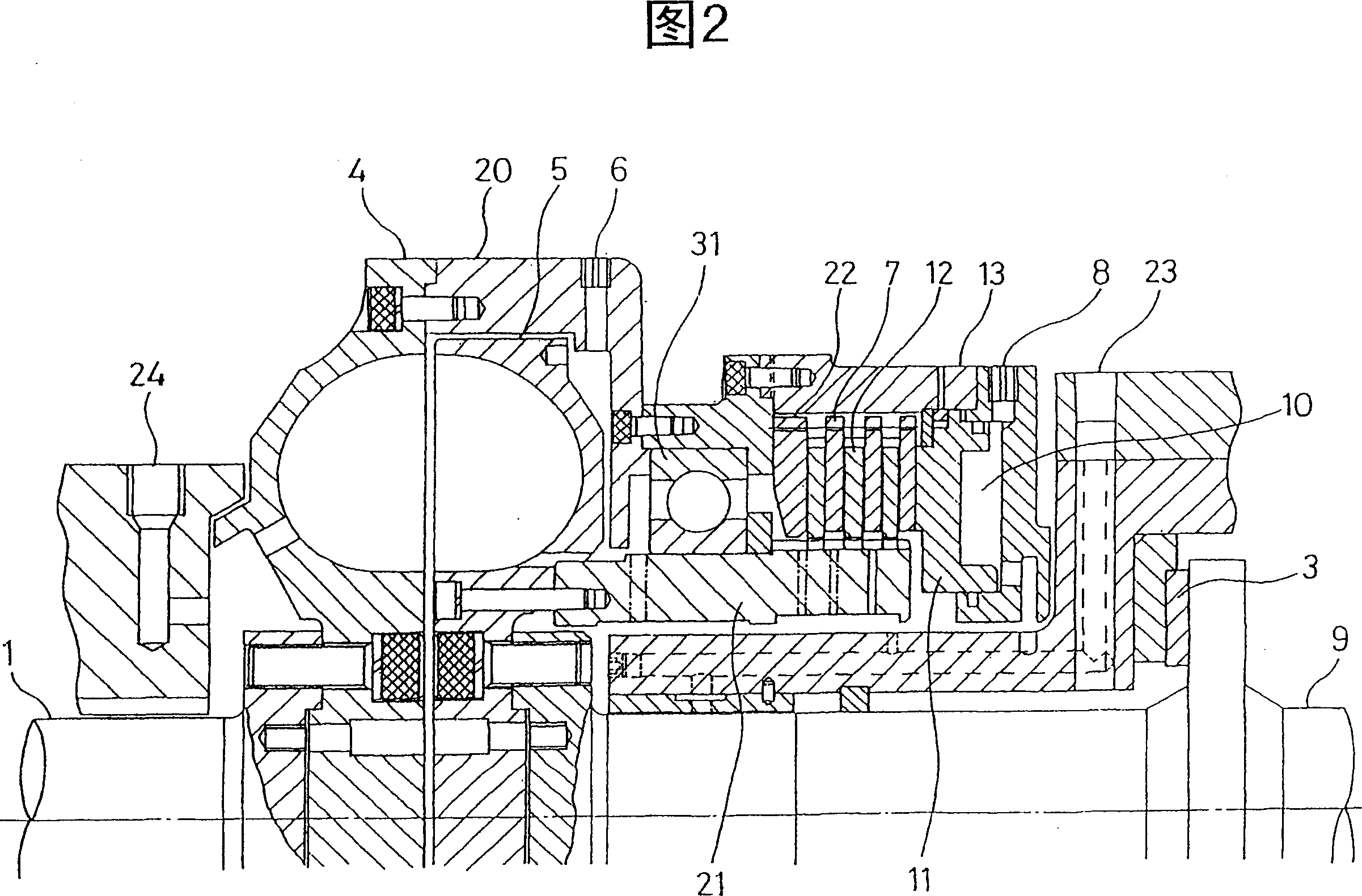

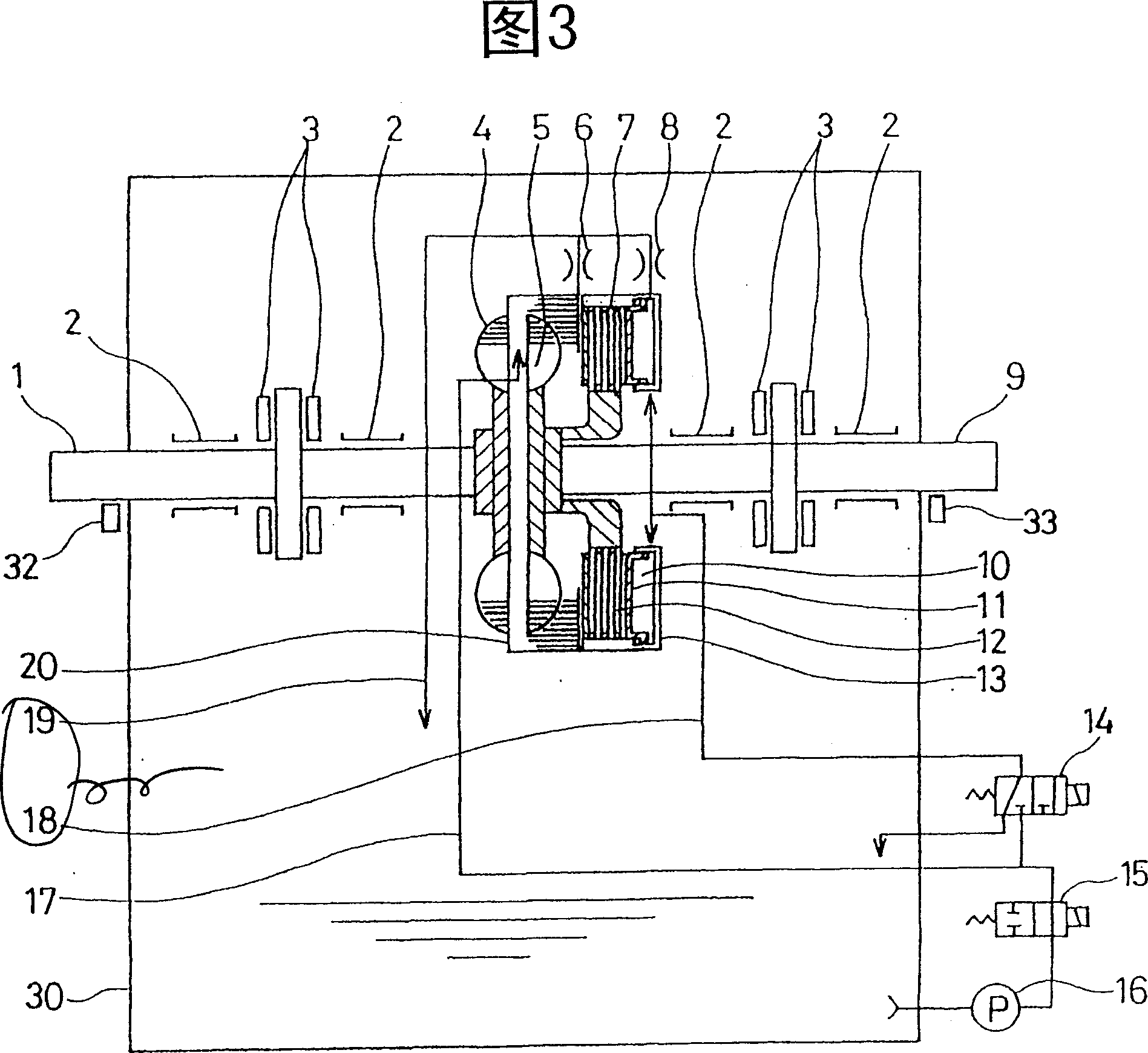

[0022] A fluid coupling according to a first embodiment of the present invention will be described below with reference to FIGS. 1 and 2 .

[0023] The fluid coupling of the present invention has a multi-plate clutch between the drive shaft side and the driven shaft side. When a pressurized fluid such as pressurized oil is supplied to the hydraulic cylinder, the multi-plate clutches are pressed against each other, thereby connecting the clutches. In this case, as a method of generating pressurized fluid, one method is to use the pressure generated by the centrifugal force applied to the oil that rotates with the drive side rotating body, and the other is to use a mechanical connection to the drive shaft Another method is to use the oil pressure generated by a hydraulic pump driven by a motor. The fluid coupling shown in Fig. 1 and Fig. 2 uses the pressure generated by the centrifugal force applied to the oil which rotates together with the driving side rotating body.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com