Rotary compressor of centralized air-breathing and exhaust

A rotary compressor and suction pipe technology, applied in the field of refrigeration compressors, can solve the problems of increasing the fluid noise of the compressor, and achieve the effects of eliminating vibration and noise, improving airflow characteristics, and smooth and continuous suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

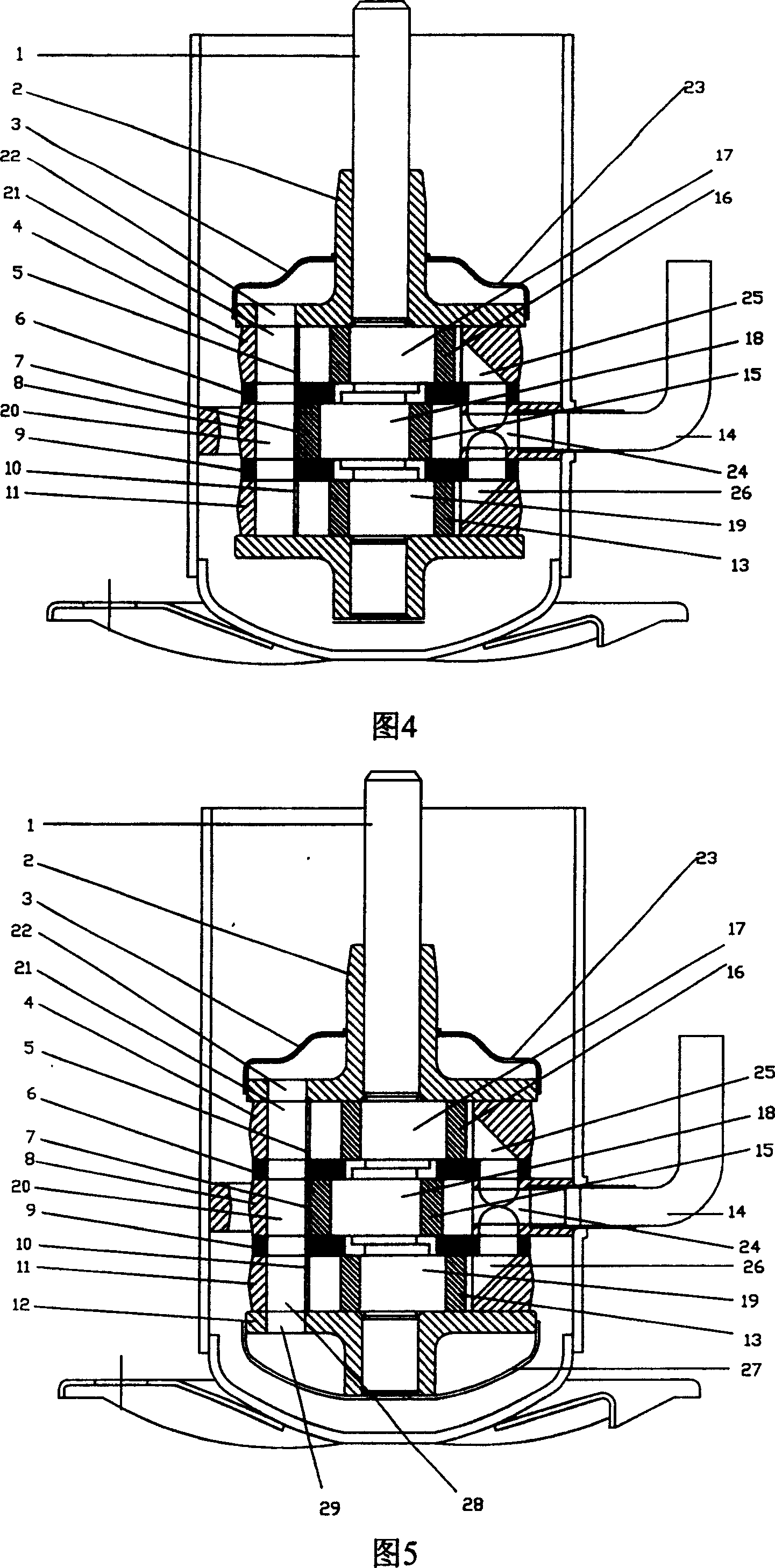

[0036] Figure 5 and Figure 6 show the second embodiment of the present invention, which is different from the first embodiment: the cylinder head 12 is also provided with a lower exhaust muffler 27, and the lower end of the exhaust passage 20 corresponds to the cylinder head 12 respectively. A lower exhaust port 28 and a cylinder head through hole 29 are provided, and the exhaust channel 20 communicates with the lower exhaust muffler 27 through the lower exhaust port 28 and the cylinder head through hole 29 . At this time, part of the gas discharged from the cylinder can enter the lower exhaust muffler 27 through the lower exhaust port 28 of the exhaust passage and the through hole 29 of the cylinder head, so that the airflow can be buffered and helps to reduce the airflow pulse.

Embodiment 3

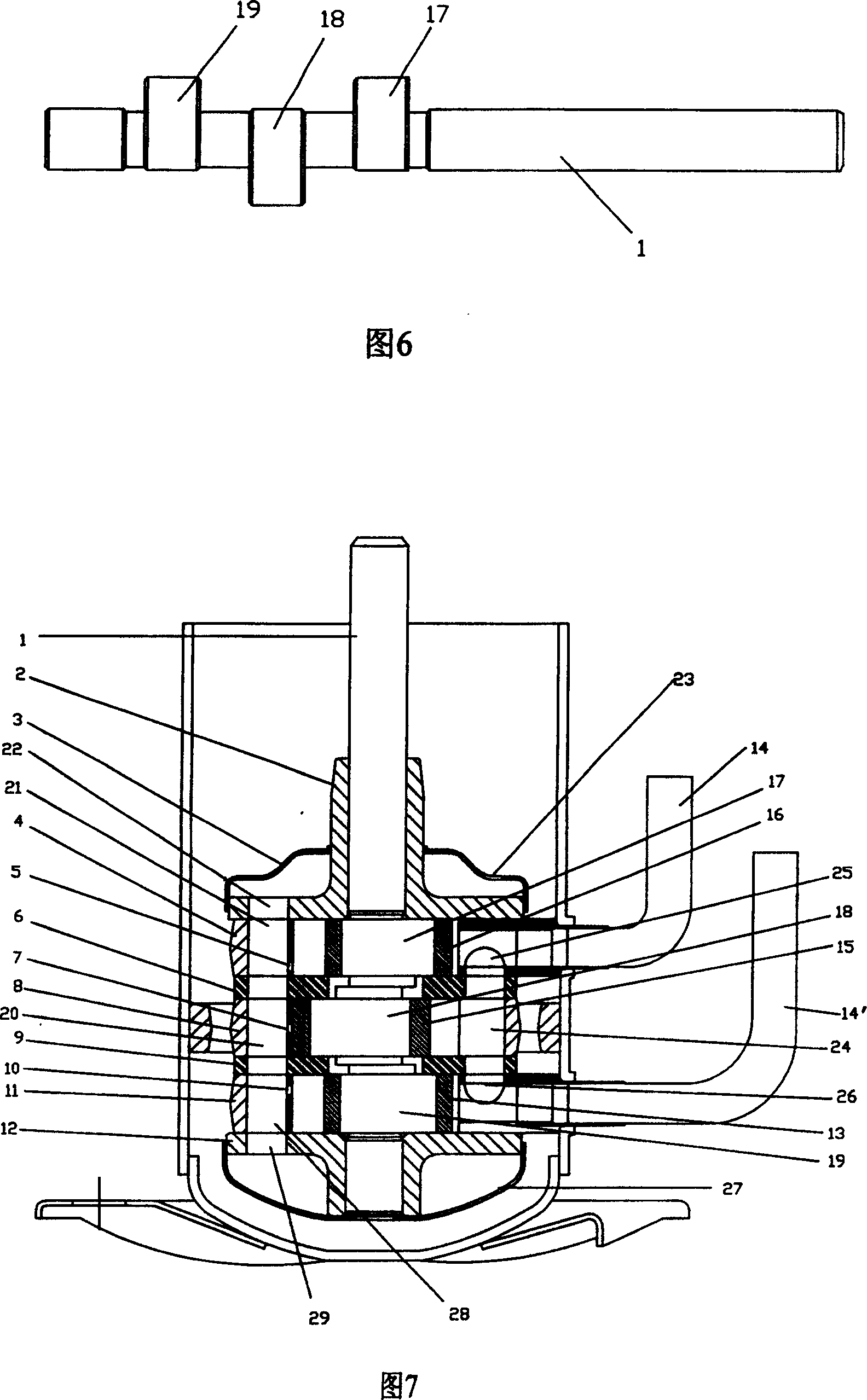

[0038] Fig. 7 describes the third embodiment of the present invention, which is different from the second embodiment: there are two suction pipes 14 and 14', which communicate with the suction holes 25, 26 of the upper cylinder 4 and the lower cylinder 11 respectively.

Embodiment 4

[0040] Figure 8 shows the fourth embodiment of the present invention, which is different from the second embodiment: a cylinder 30 is added below the lower cylinder 11, and a corresponding piston 34 and crank throw 35 are added, so that the compressor has four cylinders in total. The spatial phase difference of the four bell cranks is 90°. The upper part of its cylinder wall of the cylinder 30 is provided with an exhaust hole 31 communicating with the exhaust passage 20, and the air intake side is provided with an air intake channel 32 communicated with the air intake channels of other cylinders. Two suction pipes 14 and 14' are arranged to communicate with the suction holes 24, 26 of the two cylinders 8, 11 in the middle respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com