Control system of electric machine for dynamic changing wavecurve of electric machine energized current

A technology of motor control and motor current, applied in control system, AC motor control, single motor speed/torque control, etc., can solve problems such as battery consumption current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

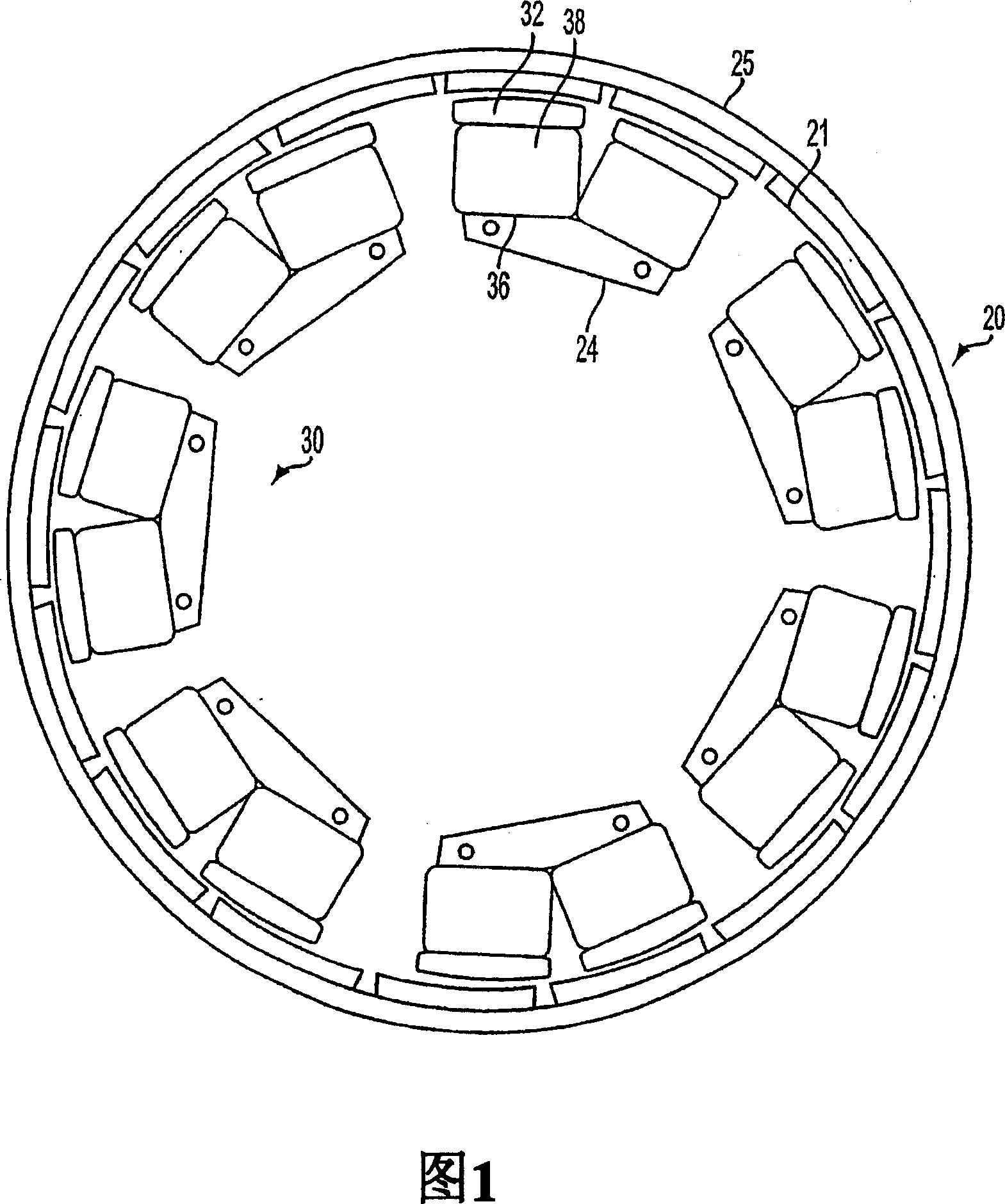

[0024]The present invention is applicable to electric machines such as those disclosed in co-pending application 09 / 826,422, although the present invention may be applied to a variety of other electric machines including permanent magnet machines. Figure 1 is thus an exemplary diagram showing rotor and stator elements as described in this application, the disclosure of which is incorporated herein. The rotor part 20 is an annular ring structure with permanent magnets 21 distributed substantially uniformly along the cylindrical support plate 25 . The permanent magnets are rotor poles that alternate polarity along the inner circumference of the annular ring. The rotor surrounds the stator part 30, the rotor and stator parts being separated by an annular radial air gap. The stator 30 includes a plurality of electromagnet core portions of the same configuration, which are evenly distributed along the air gap. Each core portion includes a generally U-shaped magnet structure 36 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com