Modifier of airproof oil for dry type gas tank

A dry gas cabinet and sealing oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of low safety factor, short service life of sealing oil, equipment corrosion, etc., to improve viscosity-temperature performance, prolong service life, The effect of retarding viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 50 parts by weight of lubricating oil are placed in the reactor, and 7 parts by weight of polymethacrylate, 10 parts by weight of ethylene-propylene copolymer, 30 parts by weight of polyisobutylene and 3 parts by weight of dialkyl disulfide are added Substitute zinc phosphate, mix thoroughly in the reactor, pass nitrogen into the reactor, stir at 70-90°C for 2 hours, cool to room temperature and collect.

[0033] Conduct industrial tests in gas cabinet installations:

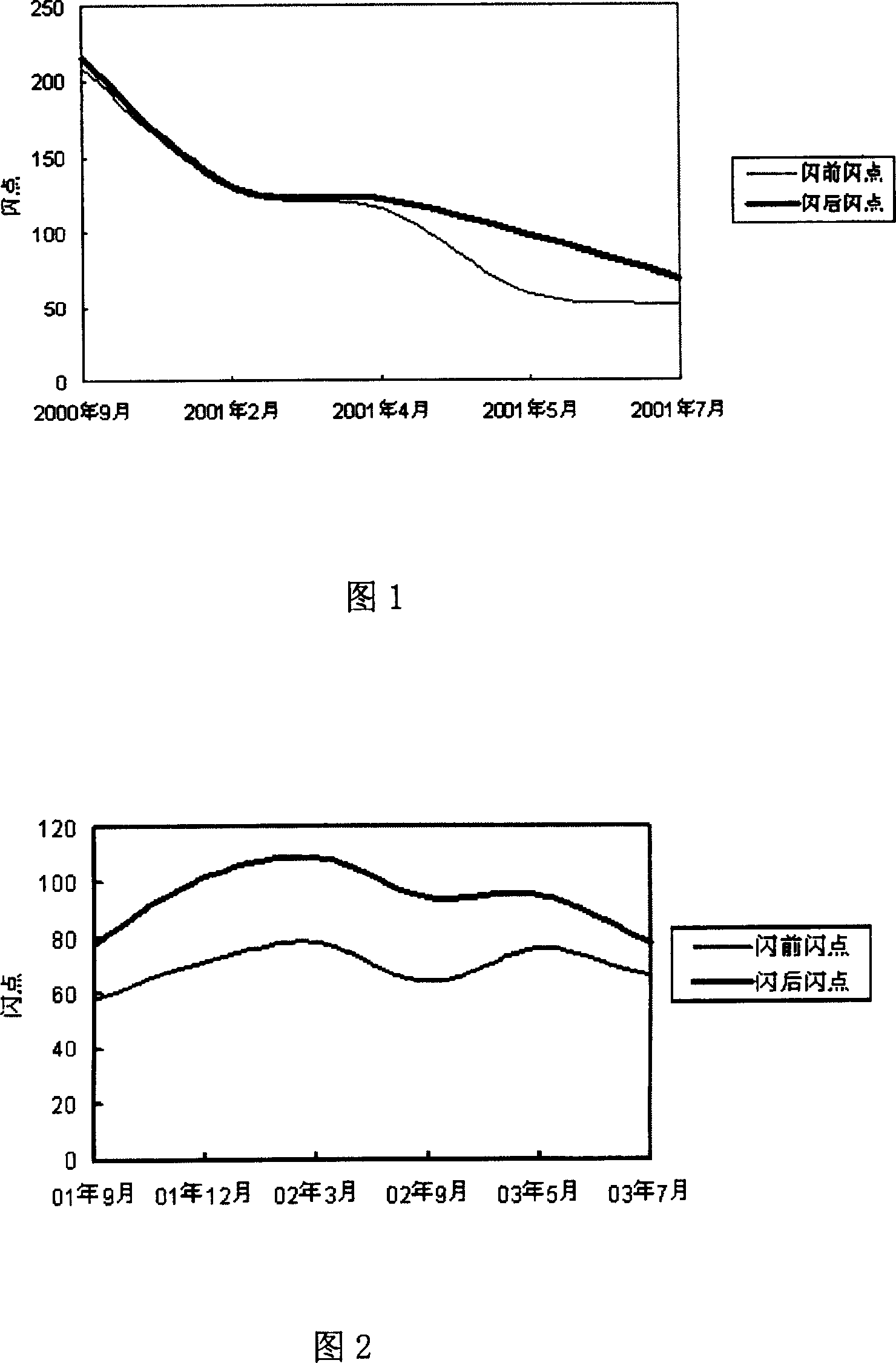

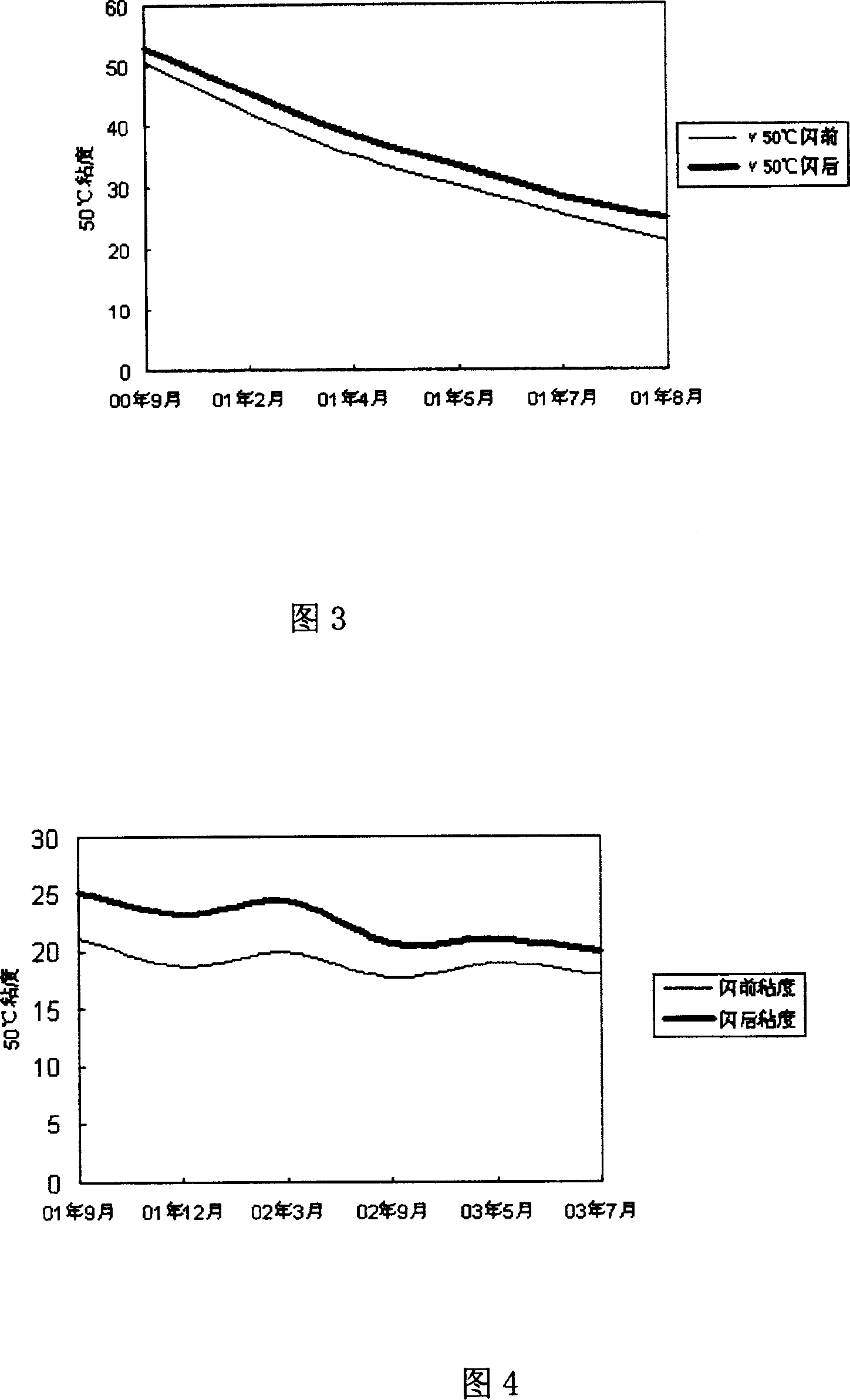

[0034] The change of the flash point of the sealing oil before and after adding the agent is shown in Figure 1 and Figure 2:

[0035] It can be seen from Figure 1 and Figure 2 that before the modifier is added, the flash point of the sealing oil shows a clear downward trend with the prolongation of the service time, and the flash point of the sealing oil has dropped by 46.97% in 5 months, which is close to the service limit of 60 °C. After adding the modifier, the decay of the flash point of the sealing ...

Embodiment 2

[0040] 20 parts by weight of lubricating oil are placed in the reactor, 5 parts by weight of polymethacrylate, 7 parts by weight of ethylene-propylene copolymer, 15 parts by weight of polyisobutylene and 2 parts by weight of dialkyl disulfide Substitute zinc phosphate, mix well in the reactor, pass nitrogen into the reactor, stir at 70-90°C for 1 hour, cool to room temperature and collect.

[0041] Carry out industrial test in gas cabinet device: result is as embodiment 1.

Embodiment 3

[0043] The lubricating oil of 80 parts by weight is placed in reactor, adds the polymethacrylate of 10 parts by weight, the ethylene-propylene copolymer of 15 parts by weight, the polyisobutylene of 45 parts by weight and the dialkyl disulfide of 5 parts by weight Substitute zinc phosphate, mix well in the reactor, pass nitrogen into the reactor, stir at 50-70°C for 3 hours, cool to room temperature and collect.

[0044] Carry out industrial test in gas cabinet device: result is as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com