Purification method and equipment for waste hydraulic oil of extruding machine

A waste hydraulic oil and purification equipment technology, applied in the direction of lubricating composition, etc., can solve the problems of ineffective removal of particle pollutants and low quality of regenerated oil, achieve good environmental protection effect, improve viscosity and viscosity-temperature performance, and purify high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

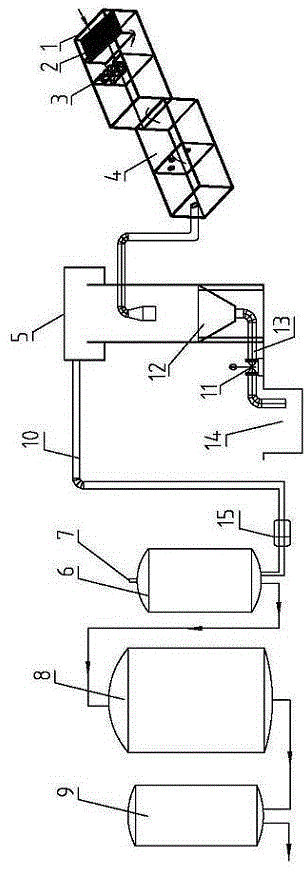

[0037] Taking the purification of hydraulic oil of aluminum alloy extruder as an example to illustrate the process of the purification method of hydraulic oil of extruder according to the present invention.

[0038] (1) Impurity removal: Pour the waste hydraulic oil into the filter tank, and remove large particles of impurities in the waste hydraulic oil through the screen of the filter tank. The waste hydraulic pressure is filtered by the filter element at the upper end of the filter tank after preliminary precipitation in the filter tank. Remove fine particle impurities in waste hydraulic oil;

[0039] (2) Sedimentation: The filtered waste hydraulic oil enters the sedimentation tank through the filter element at the upper end of the filter tank for static precipitation. The water and impurities in the waste hydraulic oil settle to the bottom and are separated, and the waste hydraulic oil passes through the upper end of the sedimentation tank. The oil outlet enters the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com