Motor dust proof bearing assembly

A dust-proof bearing and motor technology, applied in the direction of bearing components, rigid supports of bearing components, shafts and bearings, etc., can solve the problems of speed reduction, noise reduction, frictional heat generation, reduction of motor service life, and reduction of cycle efficiency, etc. Accurate speed, avoid excessive friction, ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

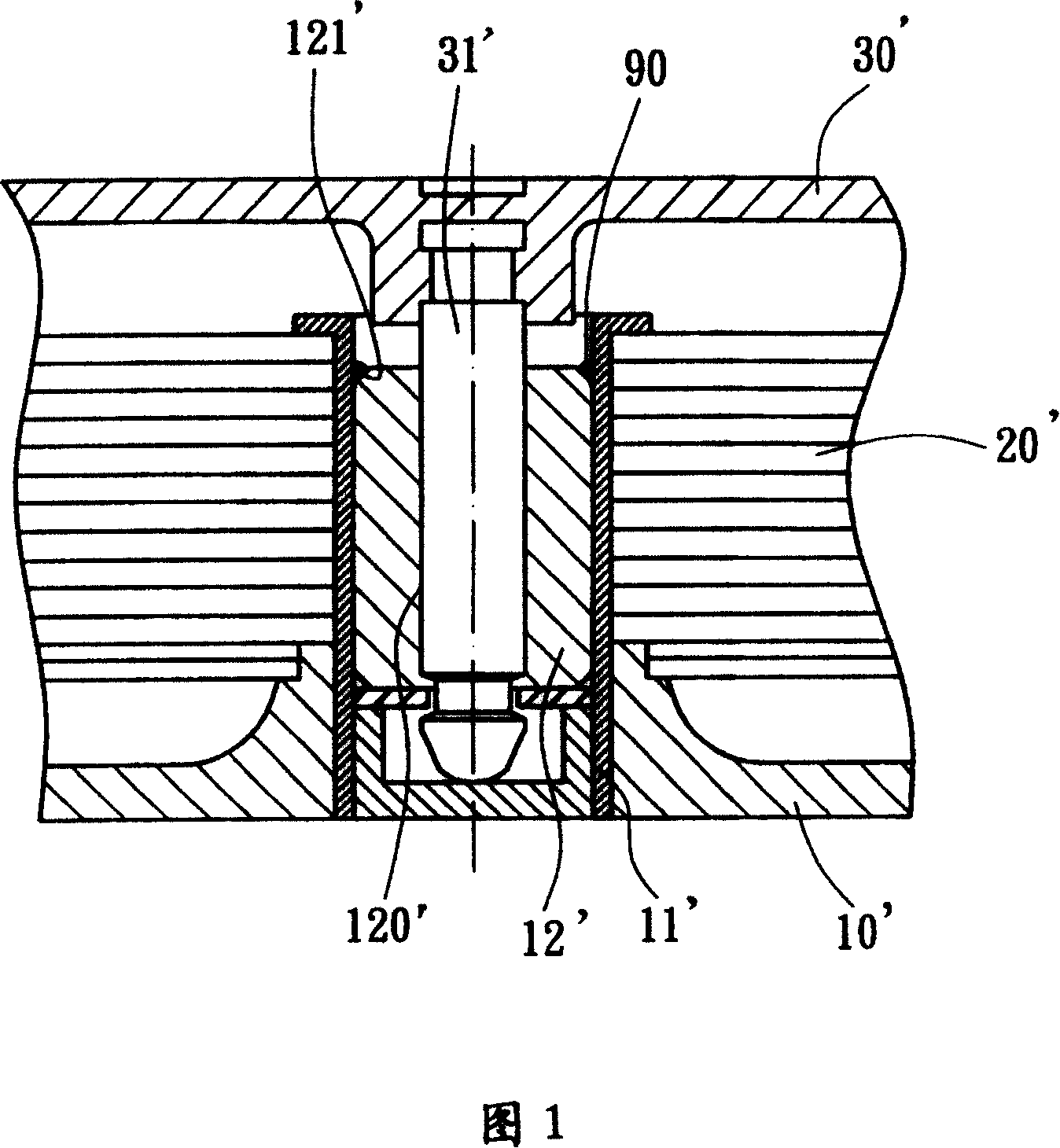

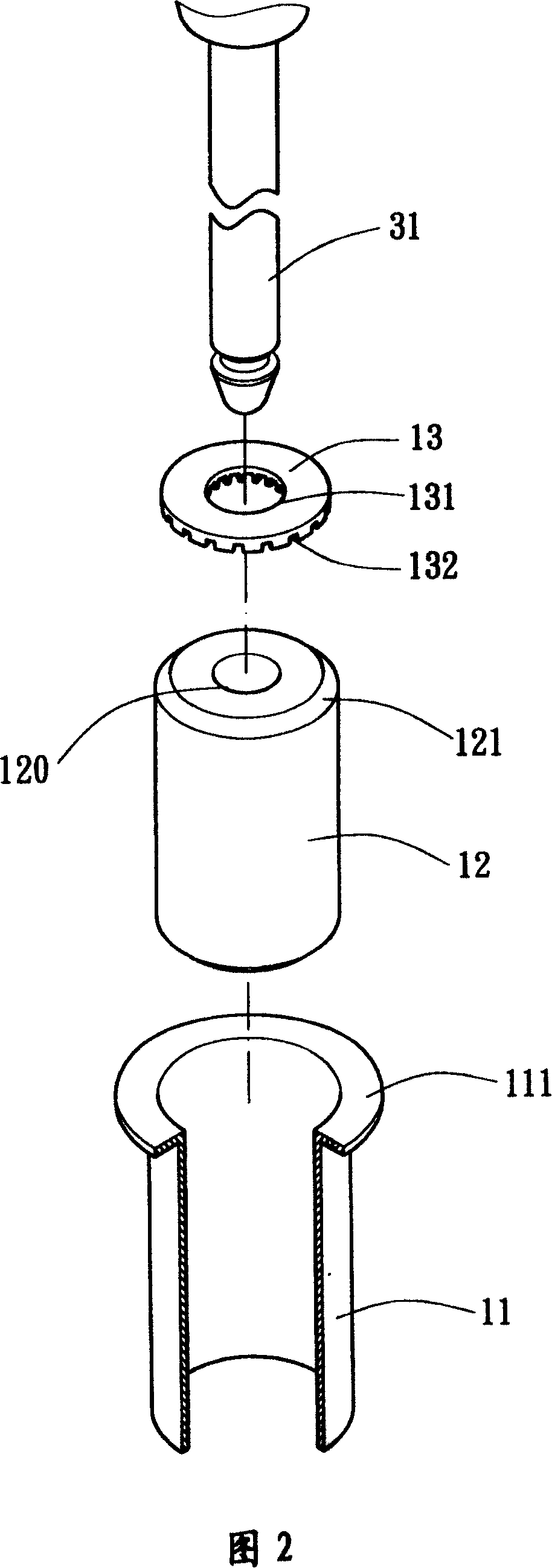

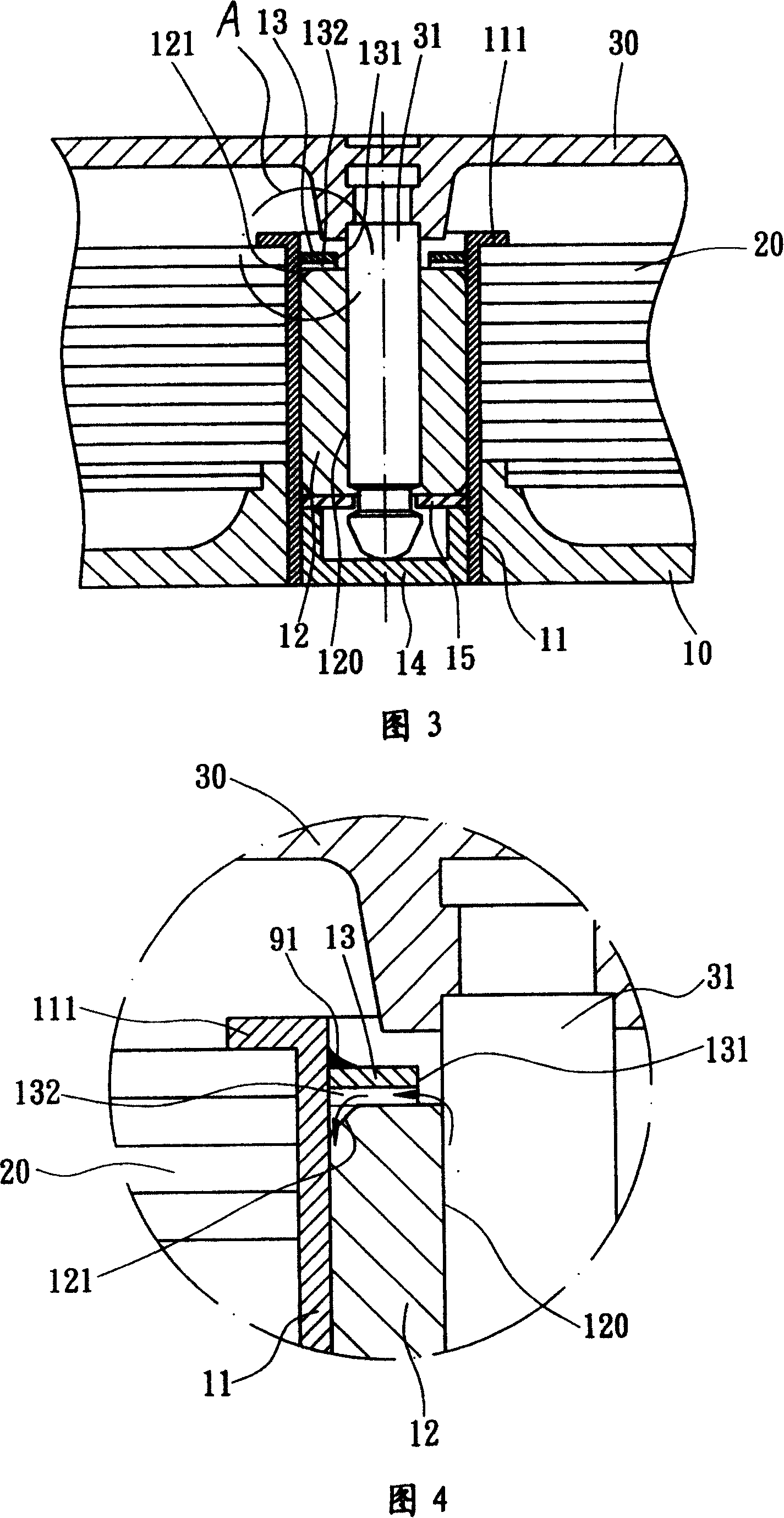

[0022] As shown in FIG. 2 , FIG. 3 , and FIG. 4 , the present invention includes a shaft tube 11 , a sleeve bearing 12 and a dust-proof sheet 13 .

[0023] The shaft tube 11 is a hollow tube with a top flange 111 formed on the top, which can be fixed on the motor base 10 and uses the top flange 111 to lock and position the stator 20 .

[0024] The bearing (sleeve bearing) 12 is selected from various self-lubricating bearings that can store oil, such as copper bearings made by powder metallurgy or ceramic bearings made by sintering. The bearing 12 is provided with a shaft hole 120 through which the shaft rod 31 of the rotor 30 passes, and a chamfer 121 is formed around the top surface of the bearing 12 . The bearing 12 is accommodated in the shaft tube 11 .

[0025] The dustproof sheet 13 can be made of plastic or metal, and has a shaft hole 131 through which the shaft 31 of the rotor 30 can pass and at least one oil return passage 132 . The oil return channel 132 is radially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com