Automatic cleaning machine for swimming pool

A technology for automatic cleaning machines and swimming pools. It is applied in swimming pools, public buildings, gymnasiums, etc. It can solve problems such as improper material selection, excessive wear of DC motor carbon brushes, and failure to reach the target temperature. Short circuit, effect of improved cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

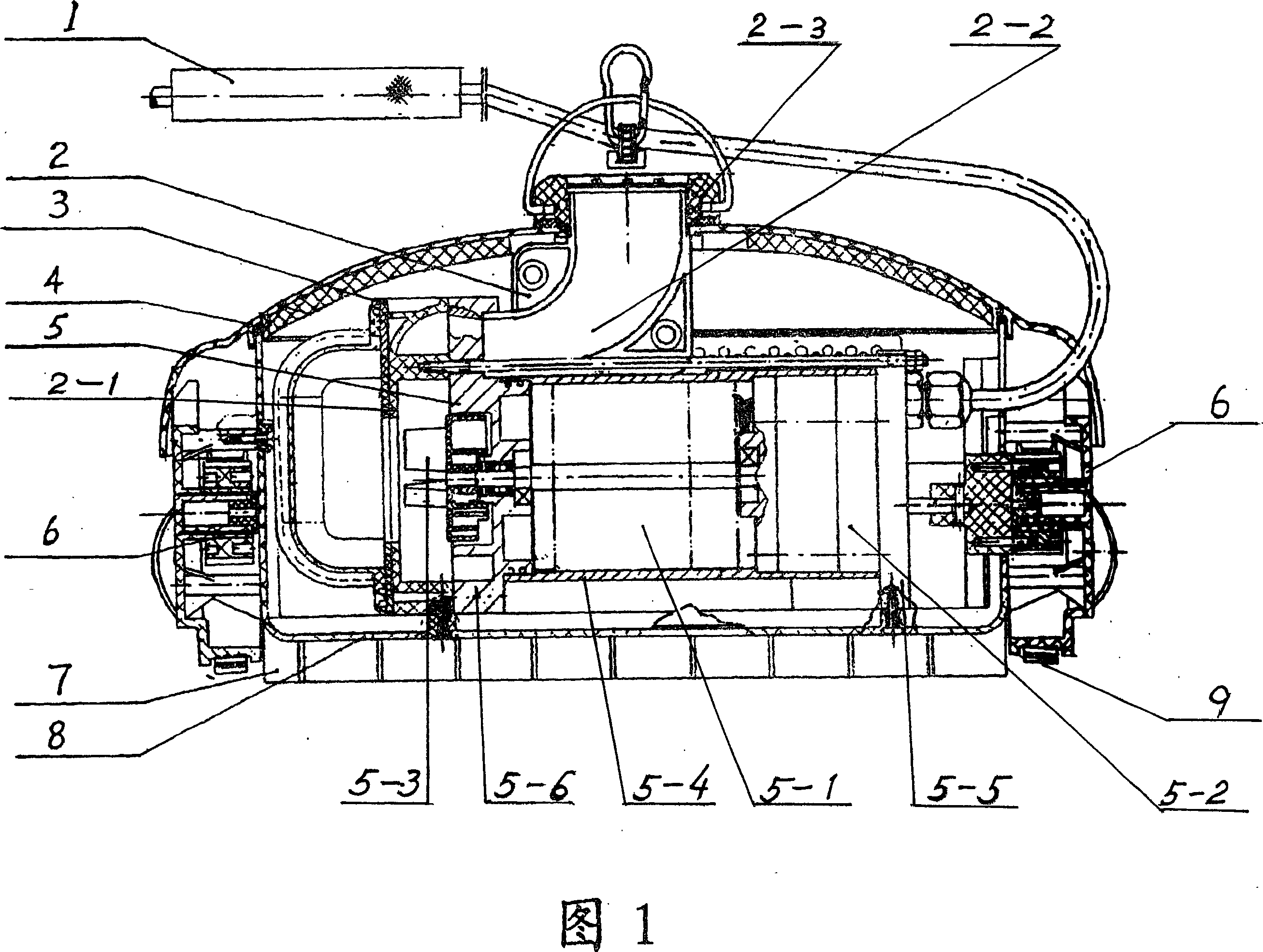

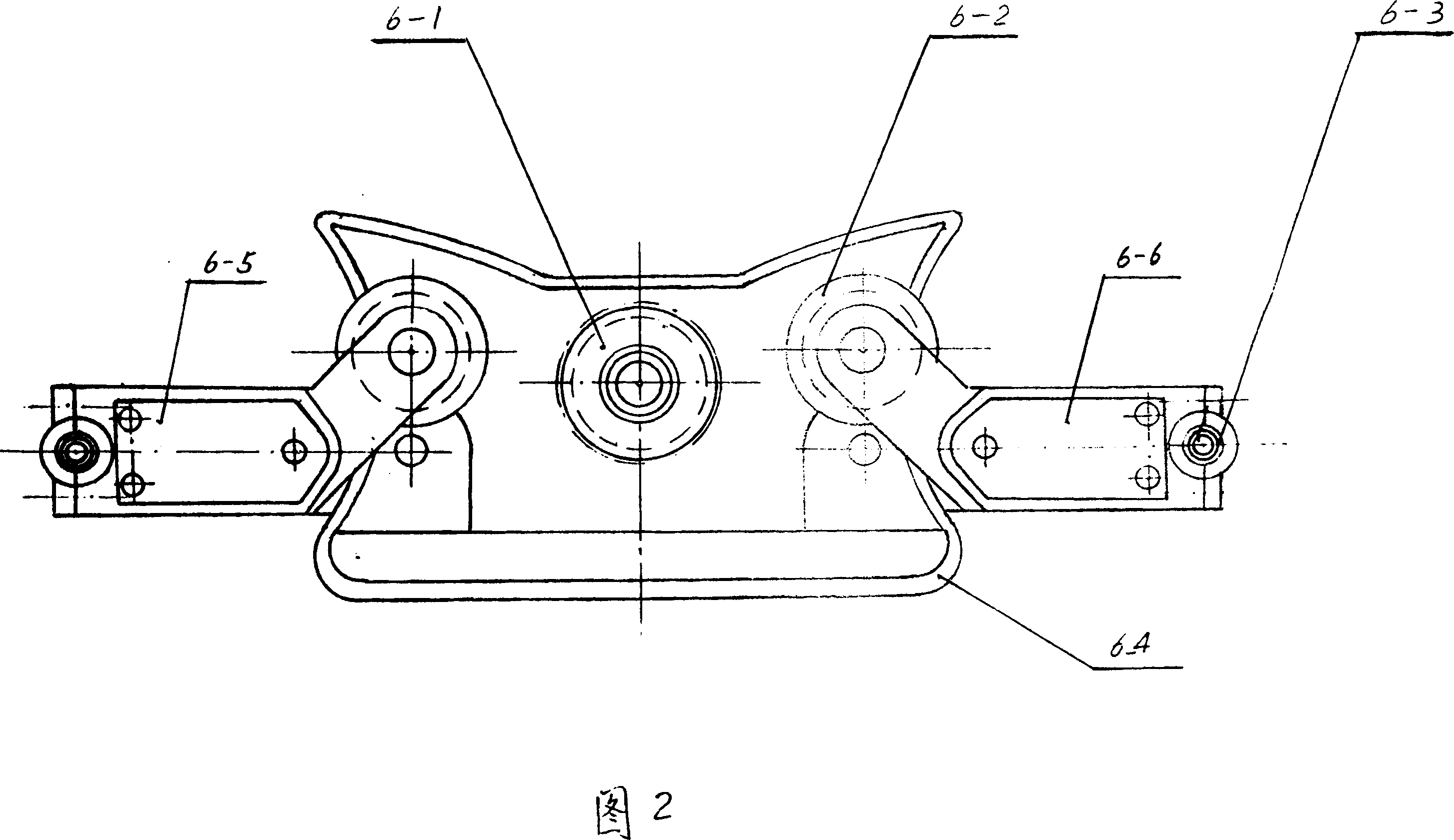

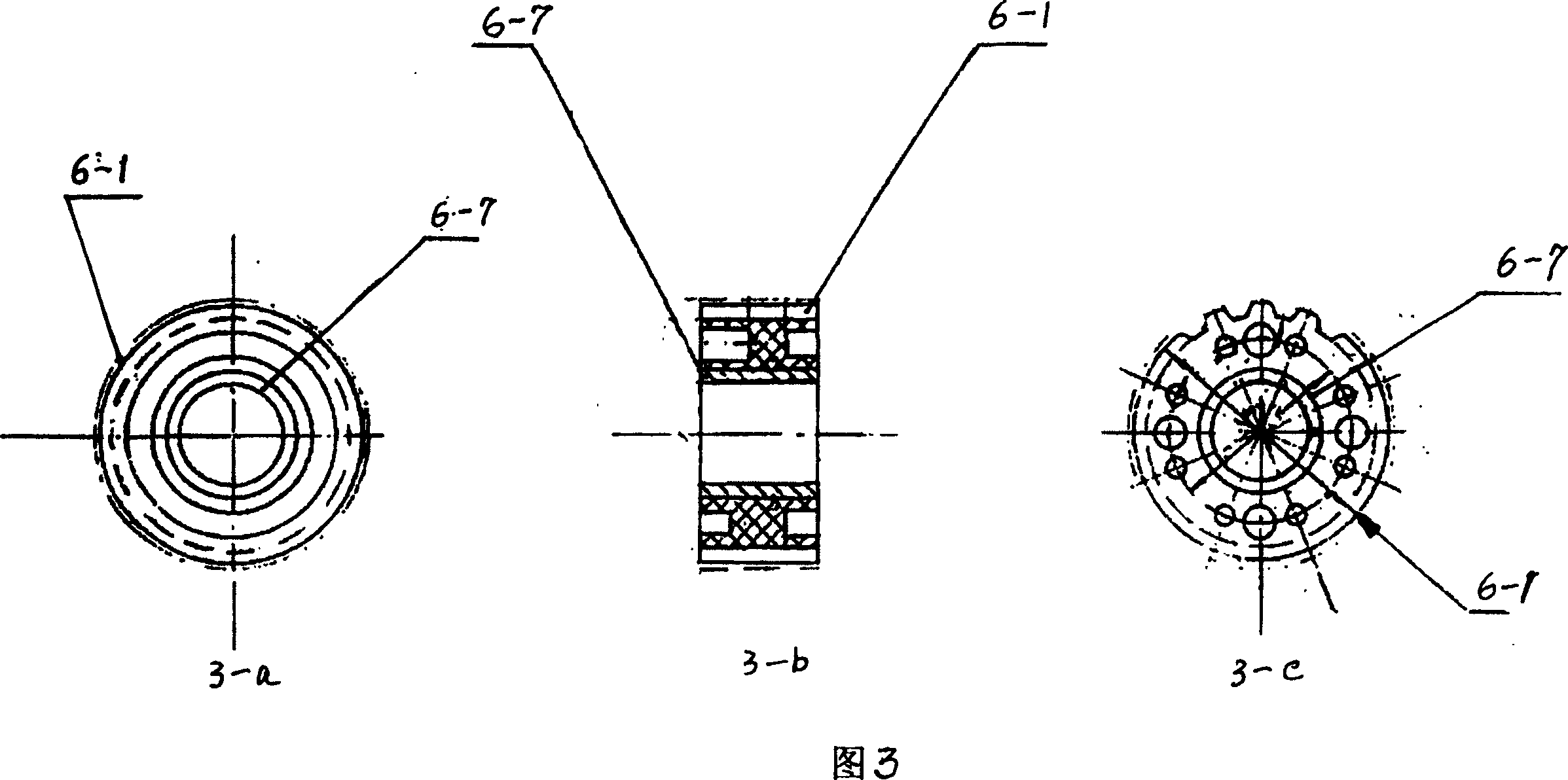

[0041]Embodiment: an automatic cleaning machine for a swimming pool (see Figure 1), characterized in that it is composed of a power control box combination 1, a drainage combination 2, a motor combination 5, a filter combination 3 composed of a filter box body and a filter pocket, The casing cover combination 4, the bracket seat combination 6 containing the transmission belt 9, the cleaning belt combination 7 and the machine casing combination 8 are formed, and the said drainage combination 2, the motor combination 5 and the filter combination 3 are placed in the casing combination 4 Inside, the power control box combination 1 and the motor combination 5 are connected by cables, the filter box in the filter combination 3 is connected with the drainage combination, the filter bag is set on the filter box, and the machine casing combination 8 is connected to the bracket seat The combination 6 is matched and connected, and the bracket seat combination 6 containing the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com