A nitrification and denitrification two-phase expanded bed reactor and sewage treatment process

A technology of nitrification and denitrification and reactors, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as high operating costs, low energy utilization rate, and difficulty in control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

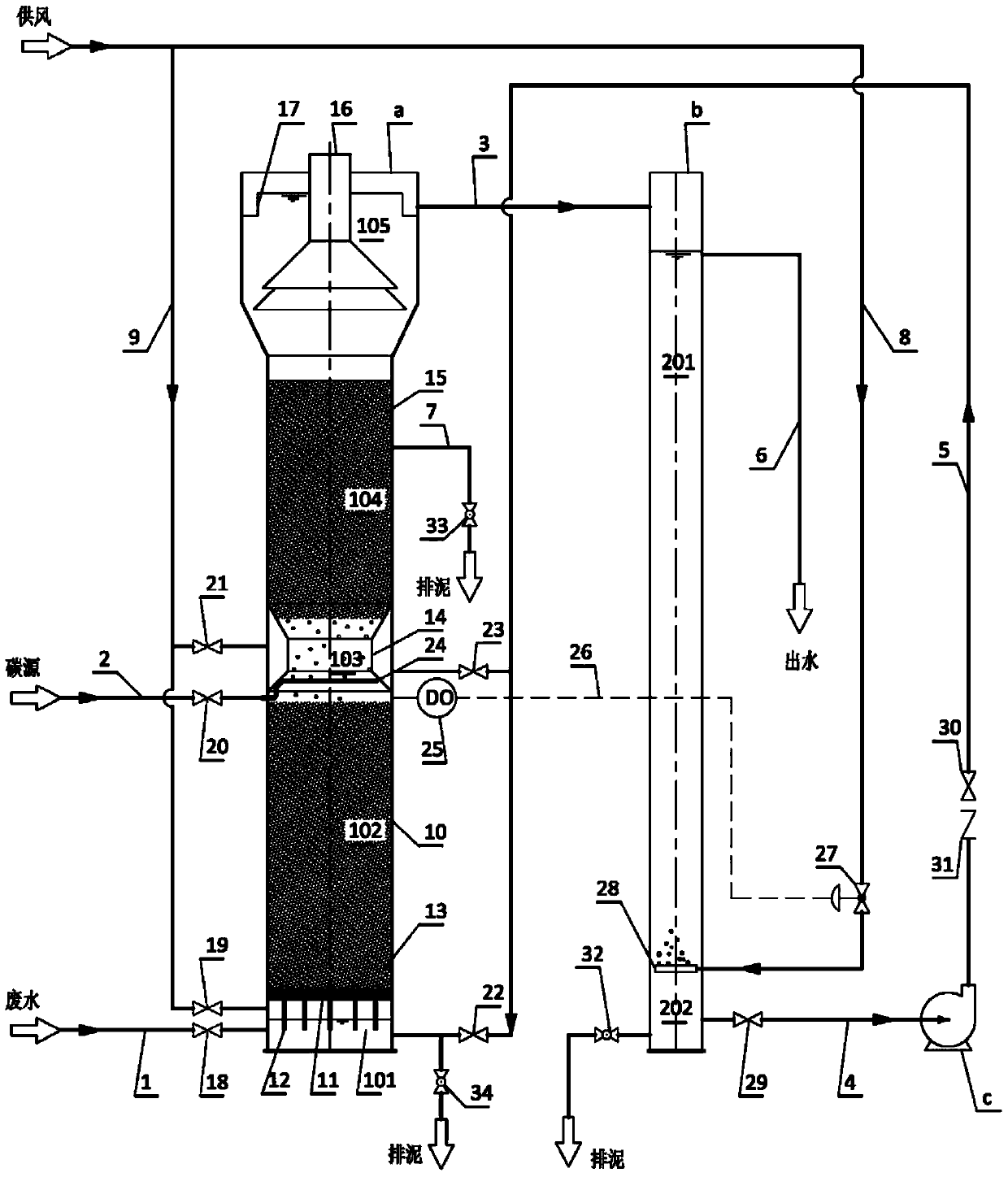

[0108] After a certain sewage is treated by conventional biochemical treatment, COD=100mg / L, NH 3 -N=50mg / L, TN=60mg / L, Q=30m 3 / h, using nitrification and denitrification two-phase expanded bed biochemical process, the effluent requirement should reach COD=60mg / L; NH 3 -N=5 mg / L, TN=10 mg / L.

[0109] The nitrification and denitrification two-phase expanded bed reactor includes reactor a, dissolved oxygen vessel b, circulating pump c and auxiliary pipelines; the operation of the nitrification and denitrification two-phase expanded bed reactor includes an operation stage, a backwashing stage and a sludge discharge stage in sequence.

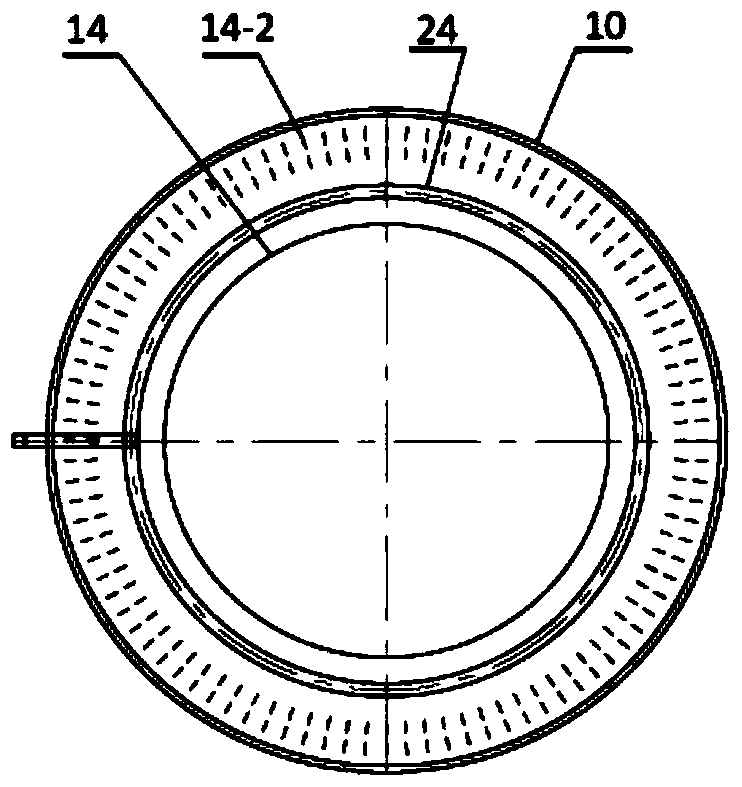

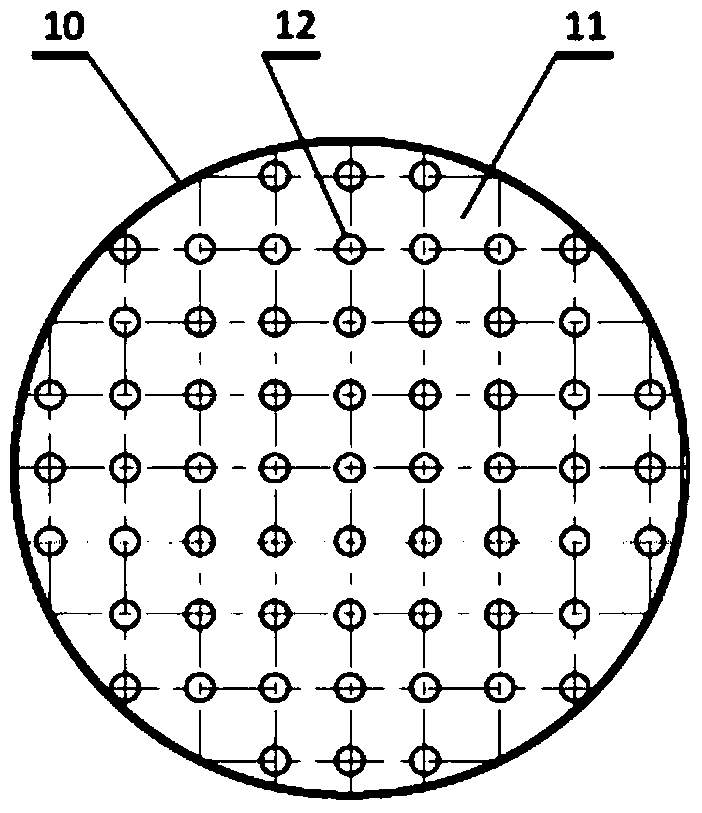

[0110] Reactor a adopts a two-stage vertical cylindrical structure with a large top and a small bottom. From bottom to top, there are bottom water distribution area 101, aerobic reaction area 102, secondary water distribution area 103, anoxic reaction area 104 and water outlet area 105. The aerobic reaction zone 102 and the anoxic reaction zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com