Digital wire feeding system

A wire feeding system and wire feeding technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of increased failure rate, long control period, and difficulty in taking into account thick and thin wires in the wire feeding system, and achieve uniform The effect of speed regulation and stability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

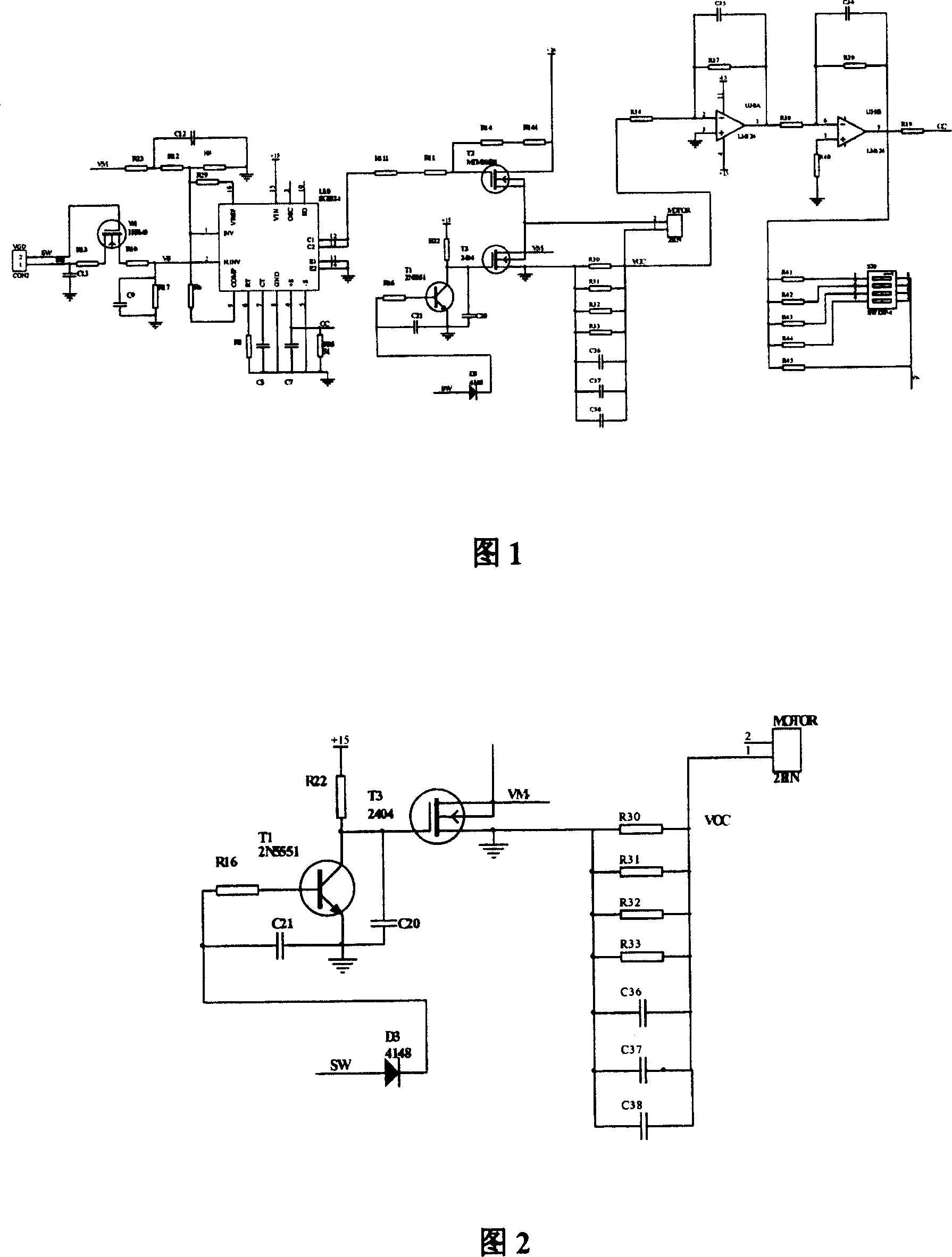

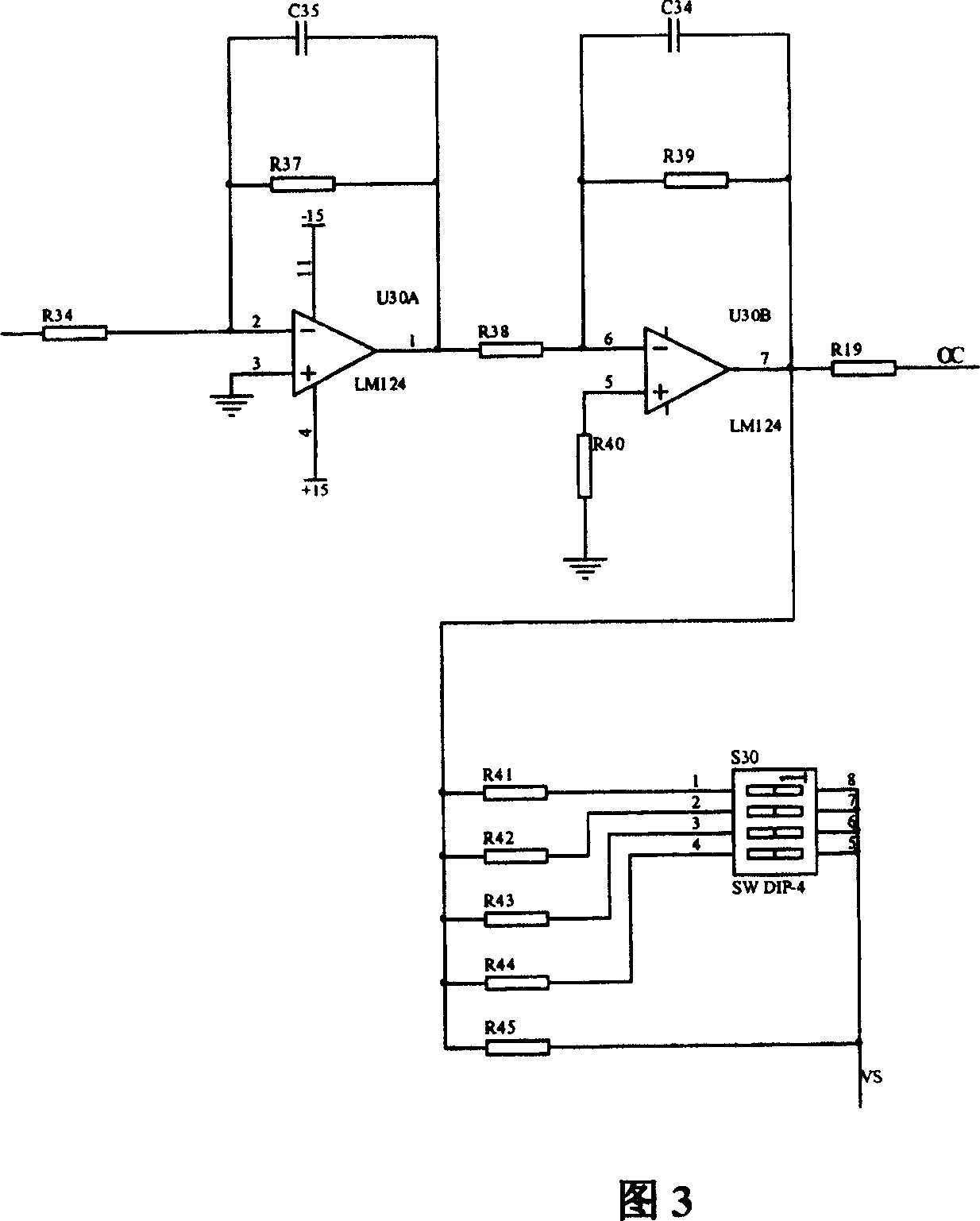

[0009] As shown in Figure 1: the digital wire feeding system of the present invention includes: a high-frequency modulation pulse circuit, an emergency brake circuit, and a wire feeding system lifting circuit. The working principle is described below in conjunction with the circuit diagram:

[0010] The given signal of wire feeding speed is given by the potentiometer on the wire feeder and is added to the collector terminal of MOSFET tube W1 through the 2 terminals of socket VGD. When the welding start signal SW is valid (high level), the gate of MOSFET tube T1 Extremely high level makes MOSFET T2 turn on, VGD signal enters the control terminal of PWM chip U10, which makes pins 12 and 13 of PWM chip U10 output pulses, and this pulse makes MOSFET T2 turn on, 24V The voltage is applied to the socket of the motor (MOTOR), so that the wire feeding motor is energized and operated, which is the working process of the pulse circuit. In this specific embodiment, the MOSFET W1 is IRF64...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com