Indirect burning separating carbon dioxide device and method for coal-fired circultating fluidized bed

A circulating fluidized bed and carbon dioxide technology, which is applied in the direction of fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, can solve problems such as high cost, low separation efficiency, and increased power generation costs, and achieve extensive social benefits and The effect of industrial application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

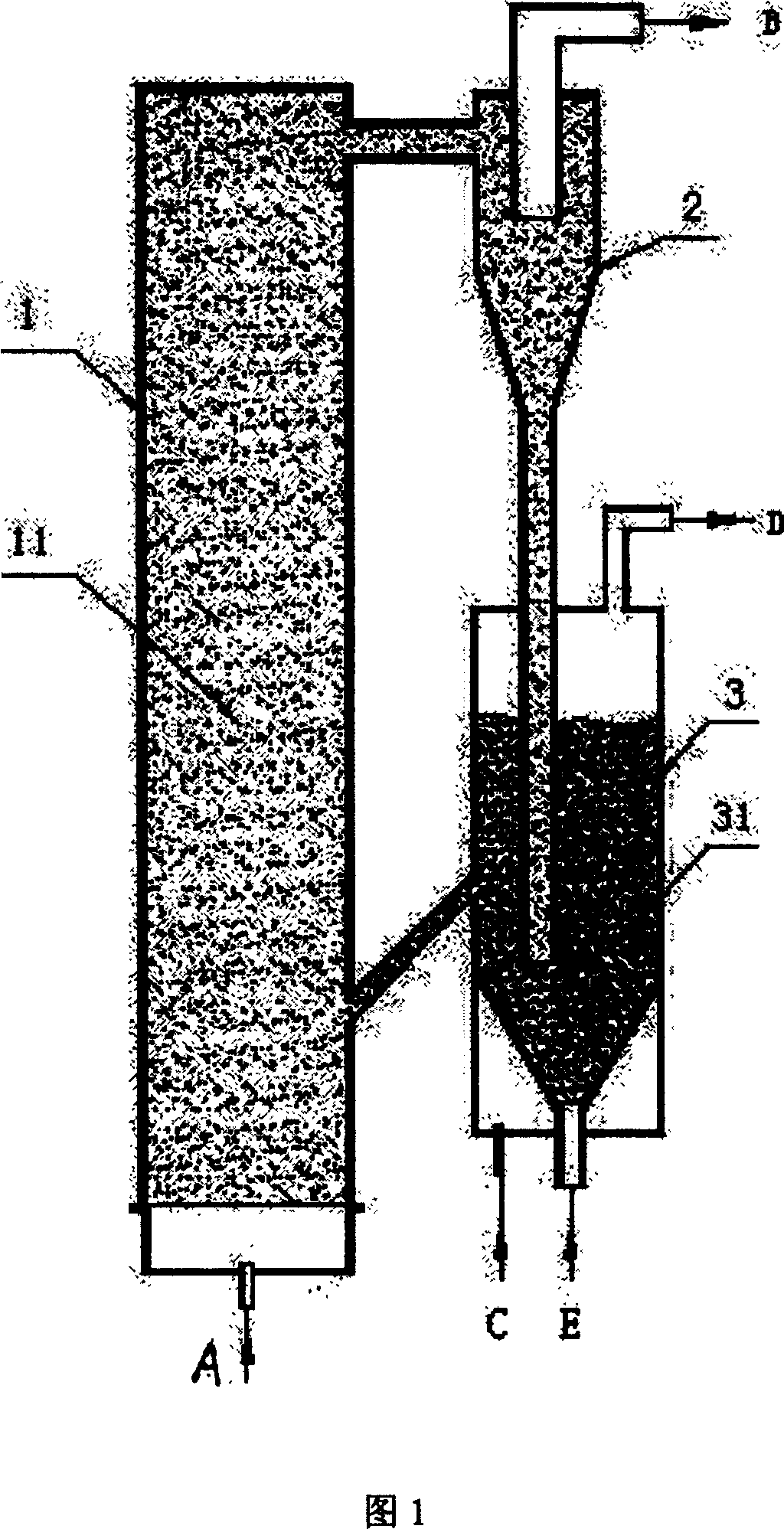

[0014] The device for indirect combustion and separation of carbon dioxide in a coal-fired circulating fluidized bed of the present invention is composed of a circulating fluidized bed 1 , a cyclone separator 2 and a spouted fluidized bed 3 . The upper part of the circulating fluidized bed 1 communicates with the upper part of the cyclone separator 2, the lower part of the cyclone separator 2 communicates with the upper part of the spouted fluidized bed 3, and the top of the cyclone separator 2 is an oxygen-poor air outlet B, and the circulating flow The lower part of the fluidized bed 1 is in communication with the spouted fluidized bed 3, the top of the spouted fluidized bed 3 is the gas outlet D for carbon dioxide and water vapor, the bottom of the circulating fluidized bed 1 is the air inlet A, and the spouted fluidized bed 3 The central area of the bottom is the water vapor / water and coal inlet E, and the bottom of the spouted fluidized bed 3 is provided with a water vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com