Blade type optimized designing method of turbine compression fluid machine

A blade profile and optimized design technology, applied to mechanical equipment, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve complex problems and achieve safe operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

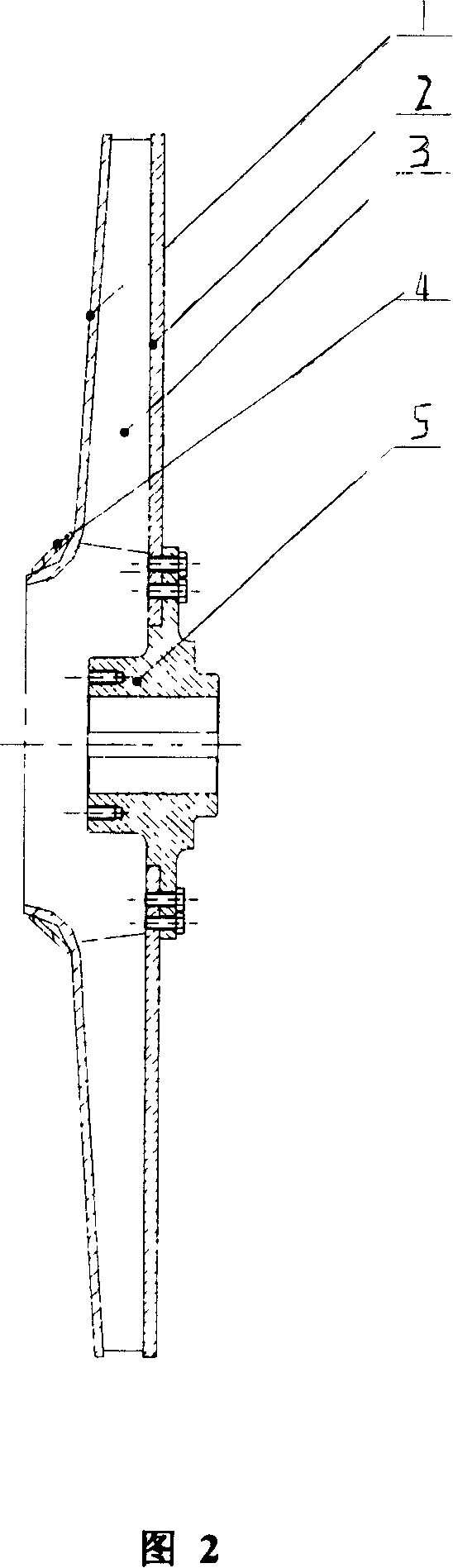

[0016] The specific embodiment of the present invention will be further described below with the design of a centrifugal fan.

[0017] Fan design air volume: 16Nm 3 / min, inlet temperature: 25°C, inlet pressure: 2.5Kpa(G), outlet pressure: 19.5Kpa(G).

[0018] Follow the steps below to optimize the design:

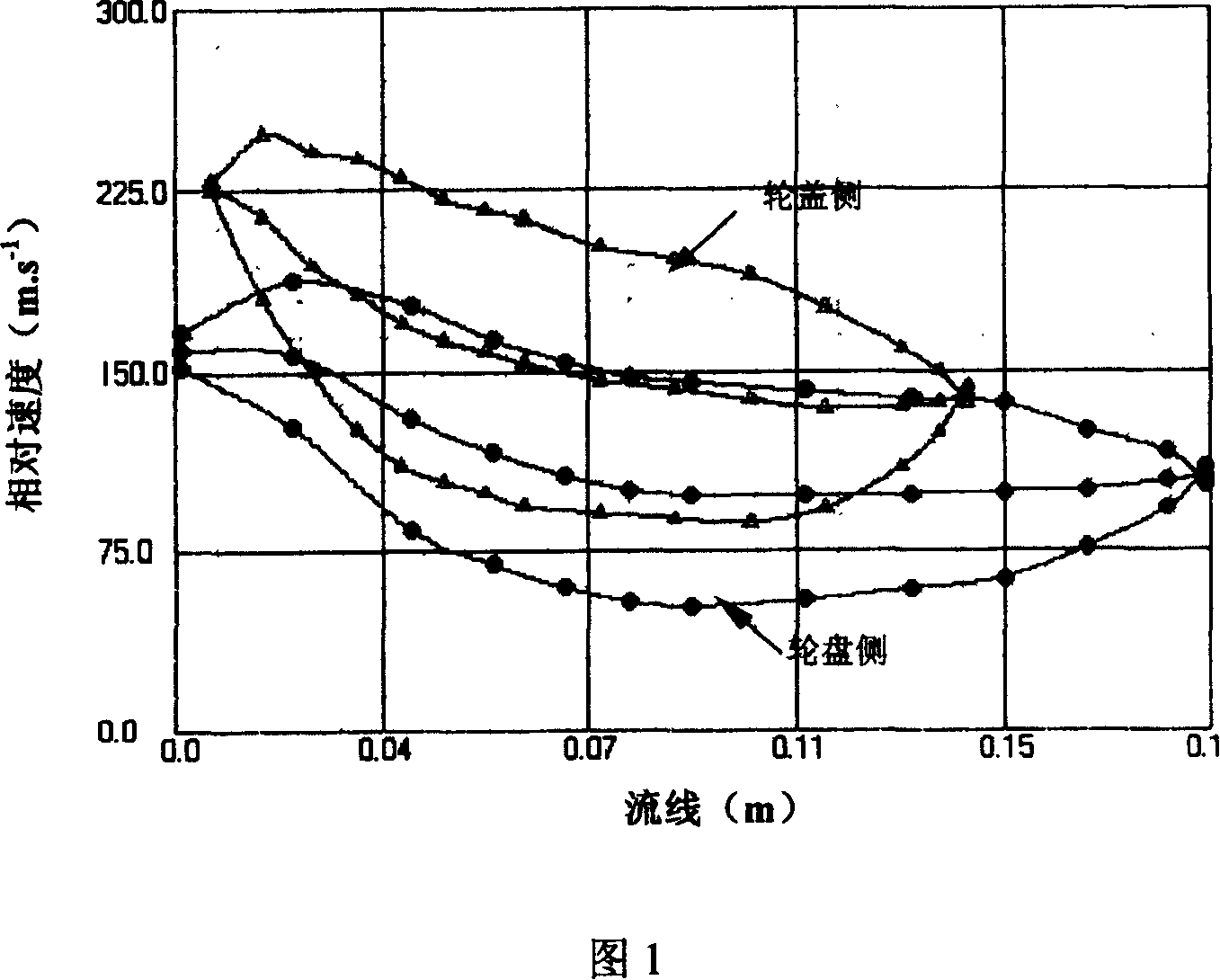

[0019] 1. According to the structural characteristics and design requirements of the centrifugal fan and the aerodynamic parameters of the fan, the flow equation controlled by the N-S equation is simplified: the internal flow of the fan is considered to be relatively constant and non-isentropic, and the effect of local viscous force and the history of viscosity are ignored The influence of accumulation, the influence of the surface of the impeller inside the fan and the growth of the boundary layer of the fan volute, mixing, gap leakage and secondary flow, etc. are all estimated by entropy increase, so that the flow process controlled by the N-S equation is simplified as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com