Roof structure for greenhouses

A construction and greenhouse technology, which is applied in the field of roof construction of greenhouses, can solve the problems of rising construction costs, blocking sunlight, and deterioration of lighting properties, and achieves the effects of reducing man-hours and labor, reducing construction costs, and improving lighting properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in more detail based on the embodiments shown in the drawings.

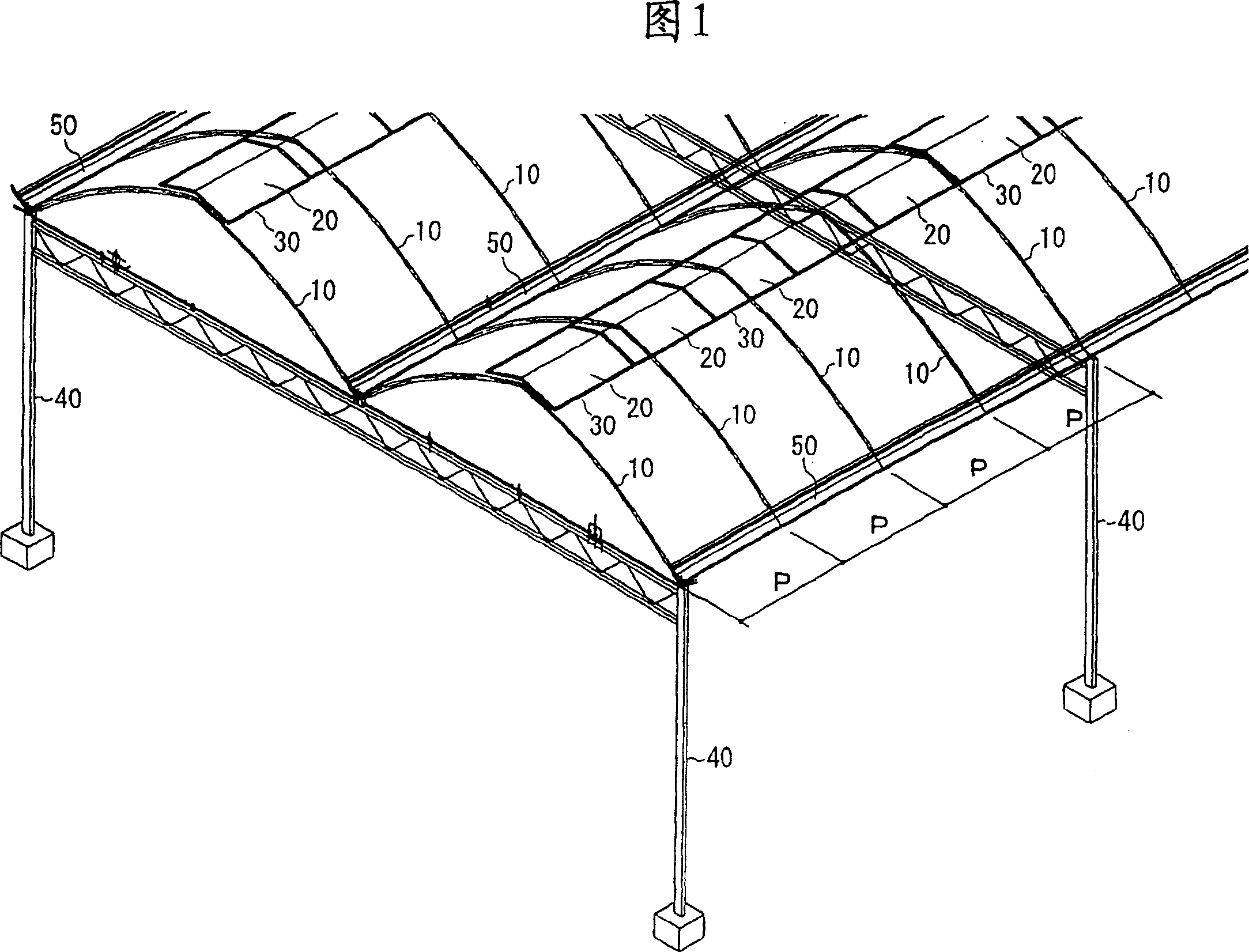

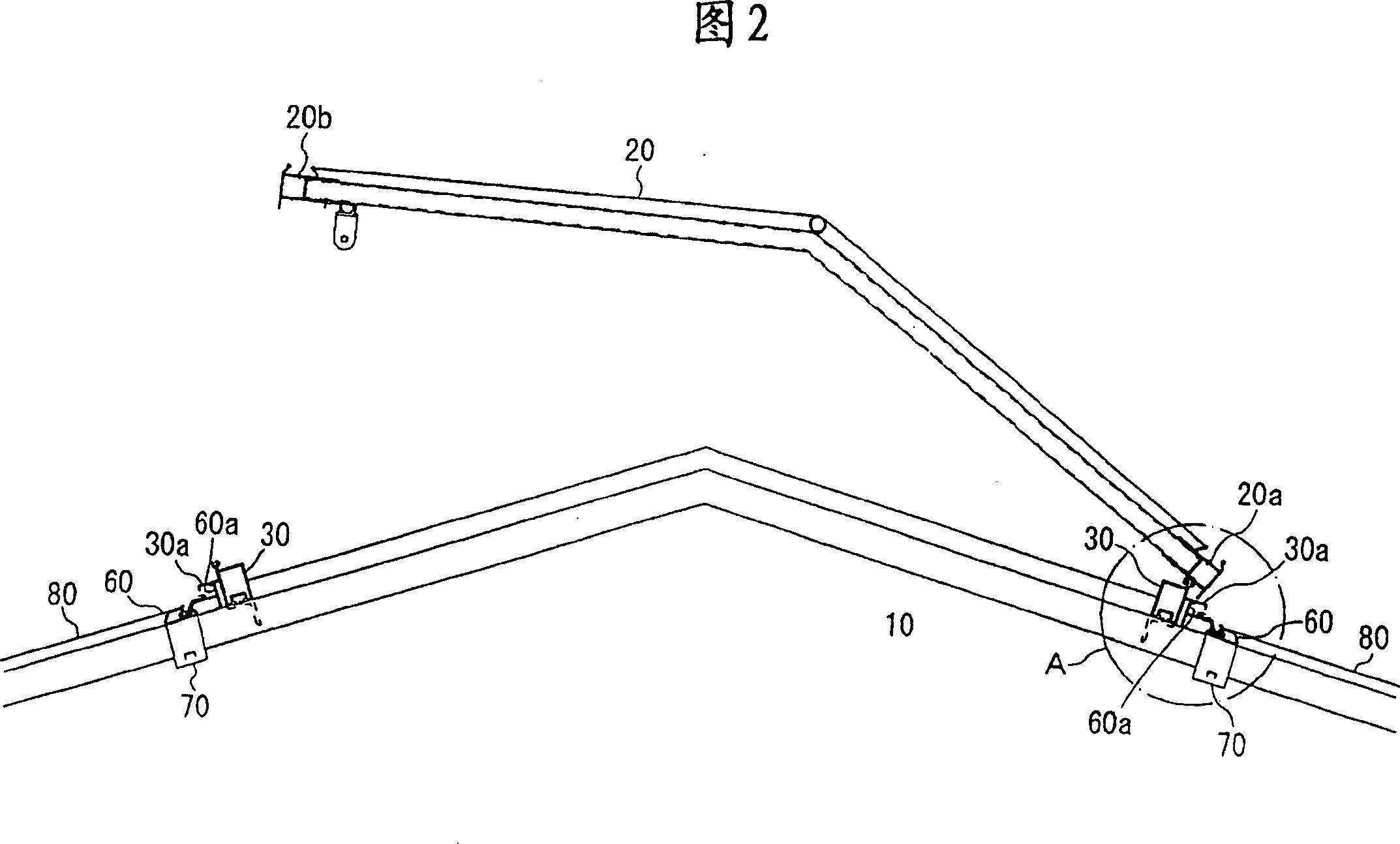

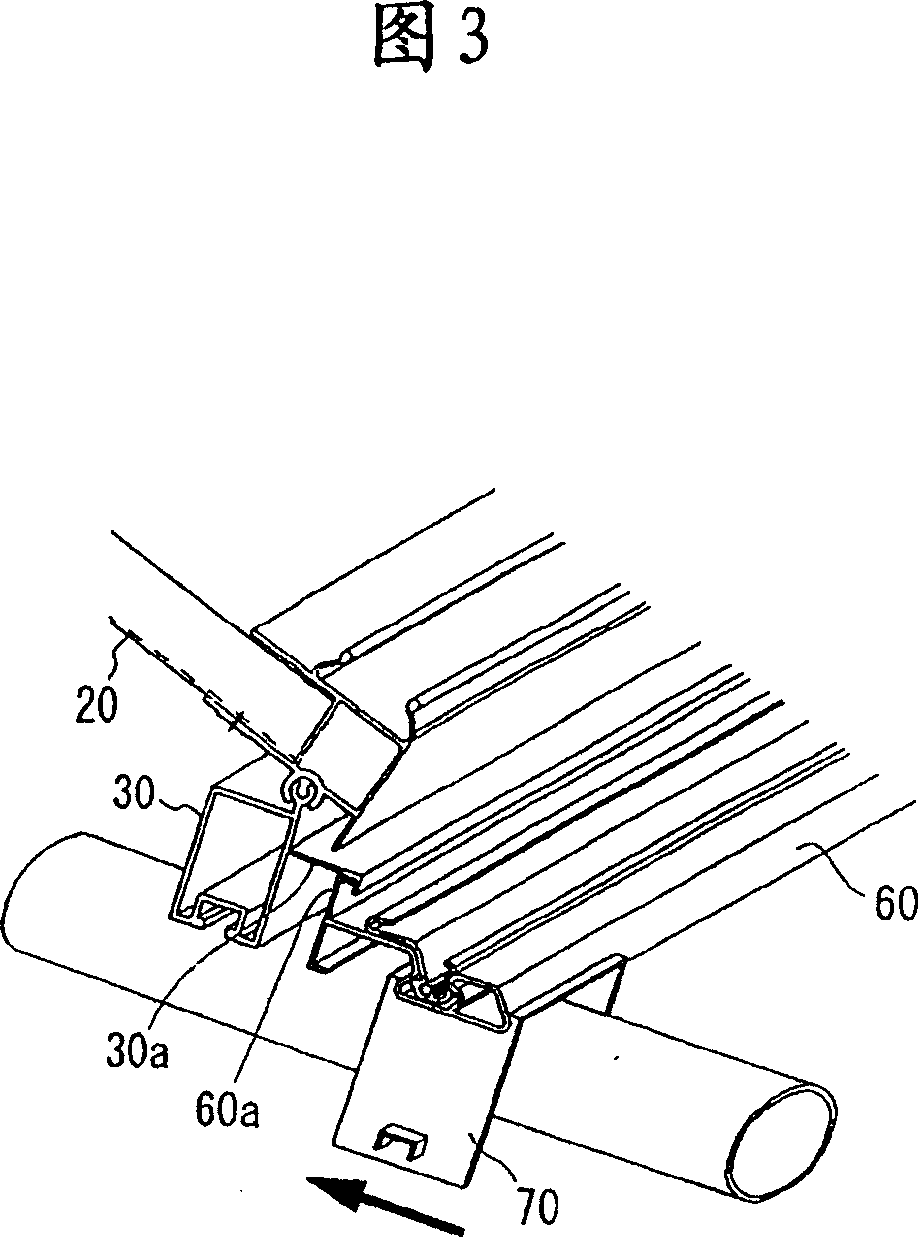

[0024] Fig. 1 is a perspective view showing main parts of a roof structure of a greenhouse according to one embodiment of the present invention. As shown in the figure, the roof according to this embodiment is constituted by including rafter materials 10 , skylights 20 , and skylight support frames 30 .

[0025] The rafter material 10 is composed of a metal tube having a circular cross section formed in an arched shape. The rafter material 10 is preferably formed by processing one pipe into an arched shape, but it may also be formed into an arched shape by connecting a plurality of pipes. By making the rafter material 10 arched in this way, there is an advantage that tension can be easily applied to the plastic film laid on the rafter material 10 . In addition, since the rafter material 10 is constituted by a metal pipe having a circular cross section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com