Multistage gas solie chemical reactor

A technology of chemical reactors and gas-solid reactors, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large reaction air flow resistance, high cycle power consumption, unreasonable structure of gas-solid chemical reactors, etc. , to achieve the effects of low cycle power consumption, small heat transfer area, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

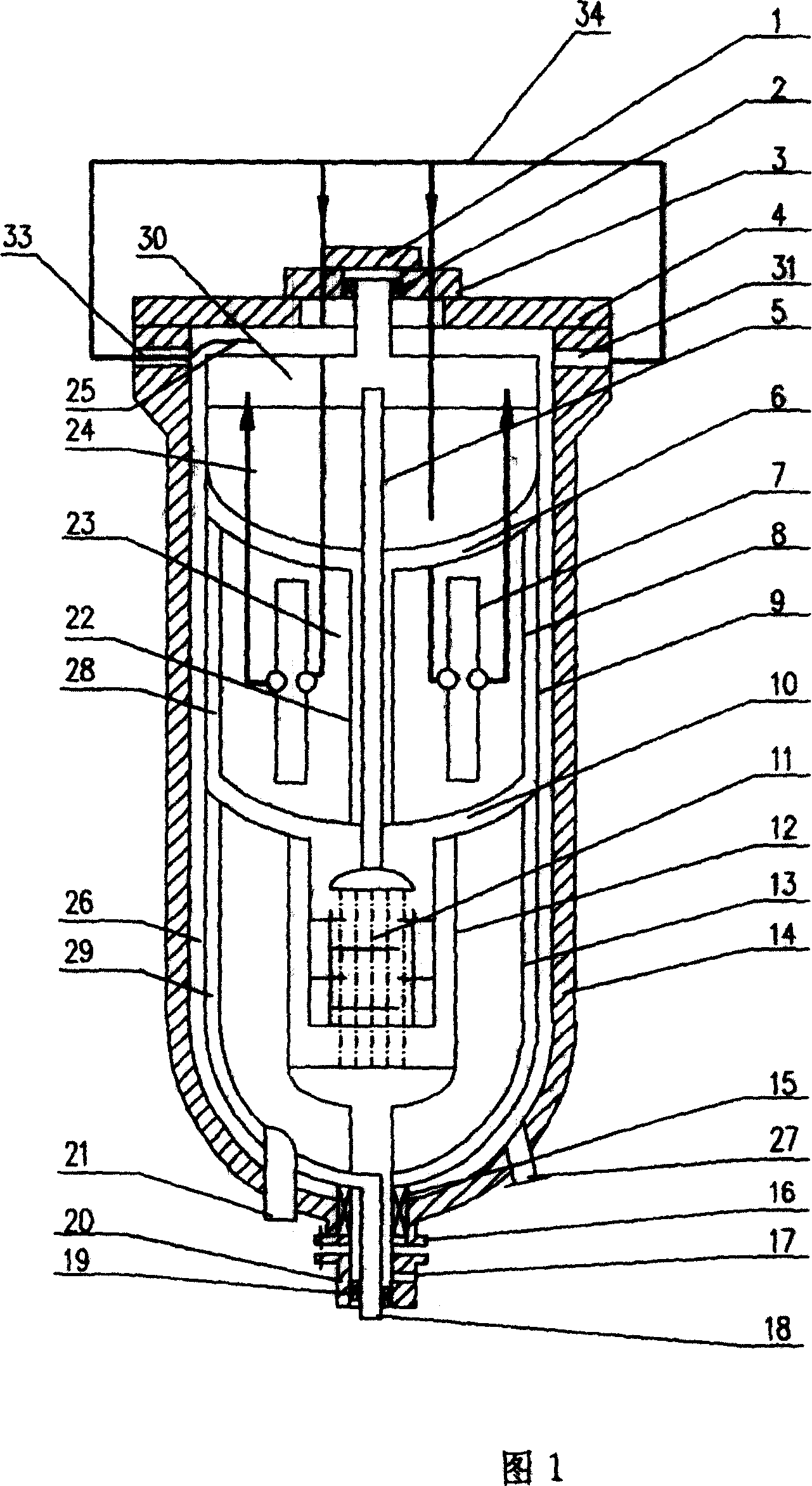

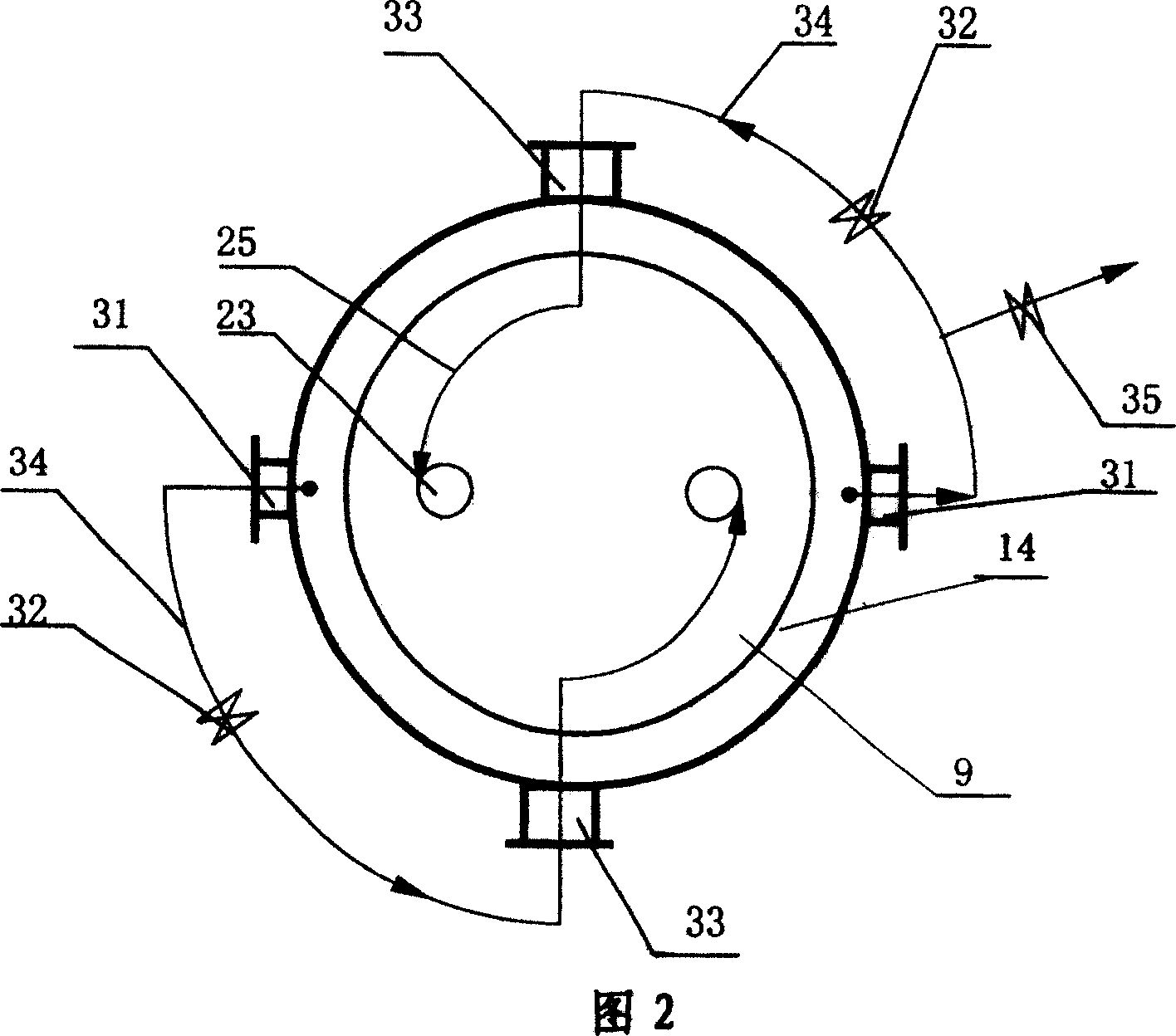

[0037] According to the drawings and the device of the present invention with the above structure, the top cover on the top of the outer cylinder 14 under pressure is shown in FIG. The number of caps is very small. It is only opened when the inner cylinder is assembled for the first time (including large, medium and small), and then only the medium and small caps are opened to fill catalysts or inspect and maintain internal parts.

[0038] There is a tee at the bottom of the reactor, which is composed of two compressed hollow short joints. The upper short joint 16 is welded to the bottom of the pressure outer cylinder 14. The lower short joint 20 is connected to the upper short joint with a flange. The lower part can be flanged or directly Welded connections to pipes or steam generators.

[0039] A packing seal 15 is added between the upper short joint 16 and the annular gap of the inserted unreacted gas inlet pipe, and a sealing packing 19 is added to the annular gap between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com