Low temperature sintered microwave dielectric ceramics and its preparing method

A technology of microwave dielectric ceramics and low-temperature sintering, applied in ceramics, inorganic insulators, etc., can solve the problems of insufficient research, lack of research on microwave dielectric properties, and lack of in-depth research, and achieve simple process, low cost, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

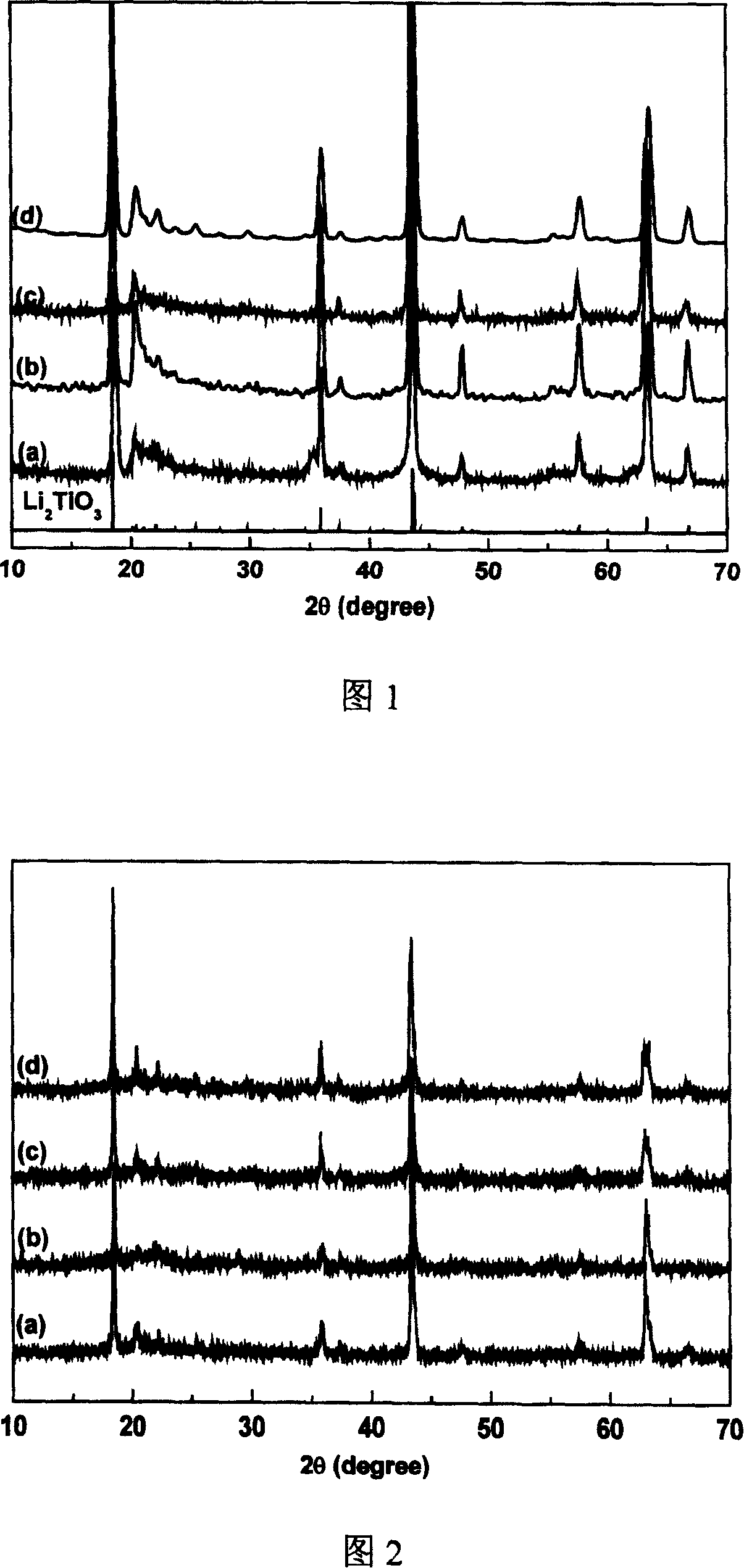

Embodiment 1

[0022] According to x=0.01 in the expression of the main crystal phase of the material, the molar ratio of Li 2 CO 3 : Nb 2 o 5 :TiO 2 =5.05:0.15:9.6 Weighing, adding deionized water according to the weight ratio of mixture and deionized water is 1:1.8, wet ball milling for 24 hours, drying at 100-150°C, putting it into a high alumina crucible, at 850°C Pre-fired for 6 hours, the powder was crushed after pre-burning, and ethanol was added according to the weight ratio of the mixture and ethanol at 1:1.2, and after 24 hours of wet ball milling, the material was discharged and dried, and granulated with 4% to 8% PVA. Under the pressure of 100-200MPa, press it into a small disc with a diameter of 16mm and a thickness of 7-8mm, deglue at 650°C, then place the sample in an alumina crucible and sinter at 1100°C for 2h, and cool naturally to obtain the material of the present invention. The dielectric properties (at room temperature) were tested by the Hakki-Colemen cylindrical d...

Embodiment 2

[0024] According to x=0.04 in the main crystal phase expression of the material, the molar ratio Li 2 CO 3 : Nb 2 o 5 :TiO 2=17:1:14 Weighing, according to the weight ratio of mixture and deionized water is 1:1.8, add deionized water, wet ball mill for 24 hours, dry at 100-150°C, put into high alumina crucible, heat at 850°C Pre-fired for 6 hours, the powder was crushed after pre-burning, and ethanol was added according to the weight ratio of the mixture and ethanol at 1:1.2, and after 24 hours of wet ball milling, the material was discharged and dried, and granulated with 4% to 8% PVA. Under the pressure of 100-200MPa, press it into a small disc with a diameter of 16mm and a thickness of 7-8mm, deglue at 650°C, then place the sample in an alumina crucible and sinter at 1100°C for 2h, and cool naturally to obtain the material of the present invention. The dielectric properties (at room temperature) were tested by the Hakki-Colemen cylindrical dielectric resonance method, a...

Embodiment 3

[0026] According to x=0.081 in the expression of the main crystal phase of the material, the molar ratio of Li 2 CO 3 : Nb 2 o 5 :TiO 2 = 10.405: 1.215: 6.76 Weighing, according to the weight ratio of mixture and deionized water is 1: 1.8, add deionized water, wet ball mill for 24 hours, dry at 100-150°C, put it into a high-alumina crucible, at 850°C Pre-fired for 6 hours, the powder was crushed after pre-burning, and ethanol was added according to the weight ratio of the mixture and ethanol at 1:1.2, and after 24 hours of wet ball milling, the material was discharged and dried, and granulated with 4% to 8% PVA. Under the pressure of 100-200MPa, press it into a small disc with a diameter of 16mm and a thickness of 7-8mm, deglue at 650°C, then place the sample in an alumina crucible and sinter at 1100°C for 2h, and cool naturally to obtain the material of the present invention. The dielectric properties (at room temperature) were tested by the Hakki-Colemen cylindrical diel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com