Sample collecting and testing device

A sample collection and damage technology, which is applied in the direction of sampling devices, test sample preparation, material inspection products, etc., can solve the problems of reduced accuracy and reliability of sample test results, difficulty in accurate results, and difficulty in achieving equipment, and achieve structural Simple, easy-to-use, inexpensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

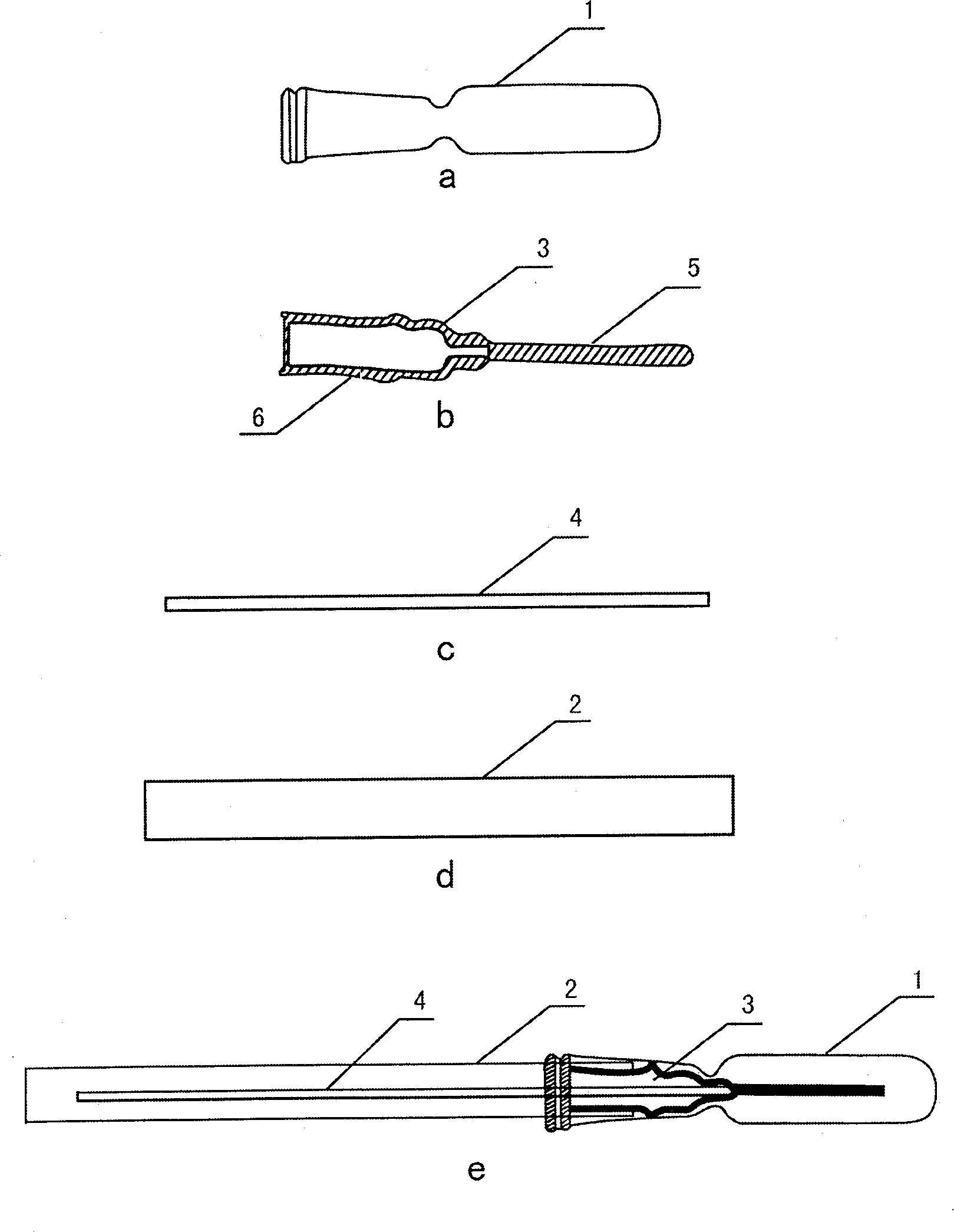

Image

Examples

Embodiment 1

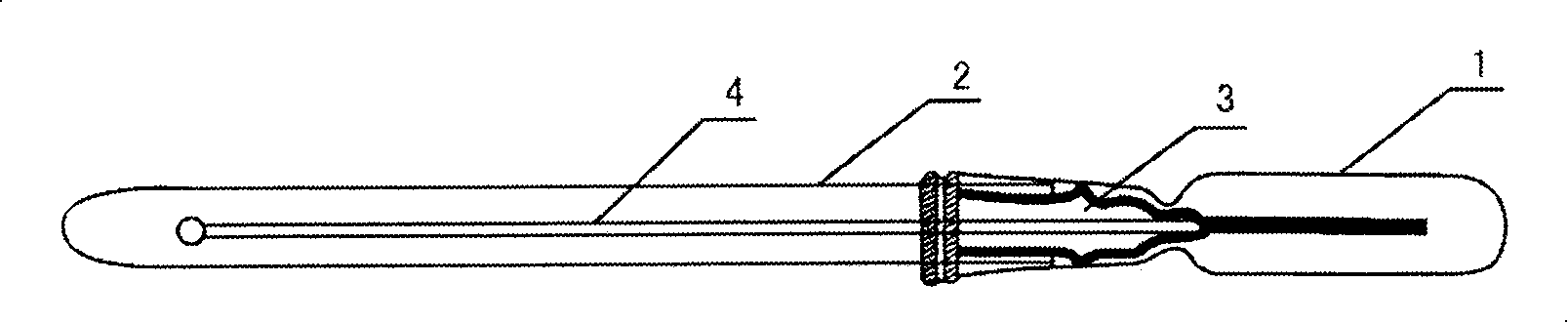

[0023] Embodiment 1 of the present invention: microorganism cultivation

[0024] Such as figure 2 , the reservoir (1) is made of soft transparent rubber, the reaction tube (2), the breakable valve (3), the thin tube (4) is made of plastic, the tail of the reaction tube (2) is sealed, the thin tube (4) A microbial culture swab is placed at the end of the tube. First remove the liquid storage bag (1), take out the thin tube (4), collect the microbial culture sample with a swab at the end of the thin tube (4), put the microbial culture reagent solution into the liquid storage bag (1), and then reduce it. When starting the experiment, break the valve needle (5) of the breakable valve (3) from the connection with the valve body (6) by hand, make the thin tube (4) communicate with the liquid storage bag (1), and then squeeze the liquid storage The capsule (1) makes the microbial culture reagent solution reach the microbiological culture swab at the tail end of the thin tube (4) t...

Embodiment 2

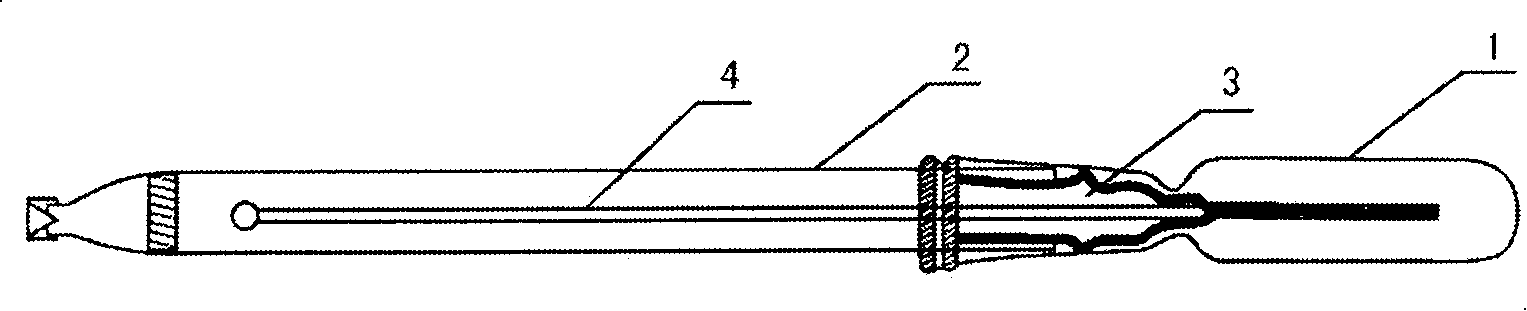

[0025] Embodiment 2: the preparation of diluent

[0026] Such as image 3 , use the inoculation loop at the end of the thin tube (4) to accurately sample, then break off the valve needle (5), so that the reaction reagent in the liquid storage bag (1) flows to the inoculation loop to mix with the sample, and an accurate diluent can be obtained. And it can be dripped into the container through the small mouth at the tail end of the reaction tube (2).

Embodiment 3

[0027] Embodiment 3: the processing of solid sample

[0028] Such as Figure 4 , use the spiral sampling cone at the end of the thin tube (4) to take a solid sample (such as feces), and then pass through the compression hole (7) in the reaction tube to make the solid sample on the spiral sampling cone reach the required amount, and then break the valve needle (5) Make the reaction reagent in the liquid storage bag (1) flow to the spiral sampling cone to react with the solid sample to obtain the desired result.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com