Frozen powder injection of tiopronin

A technology of tiopronin and freeze-dried powder injection, applied in the field of new tiopronin freeze-dried powder injection and its preparation, can solve the problems of thermal instability, poor stability, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

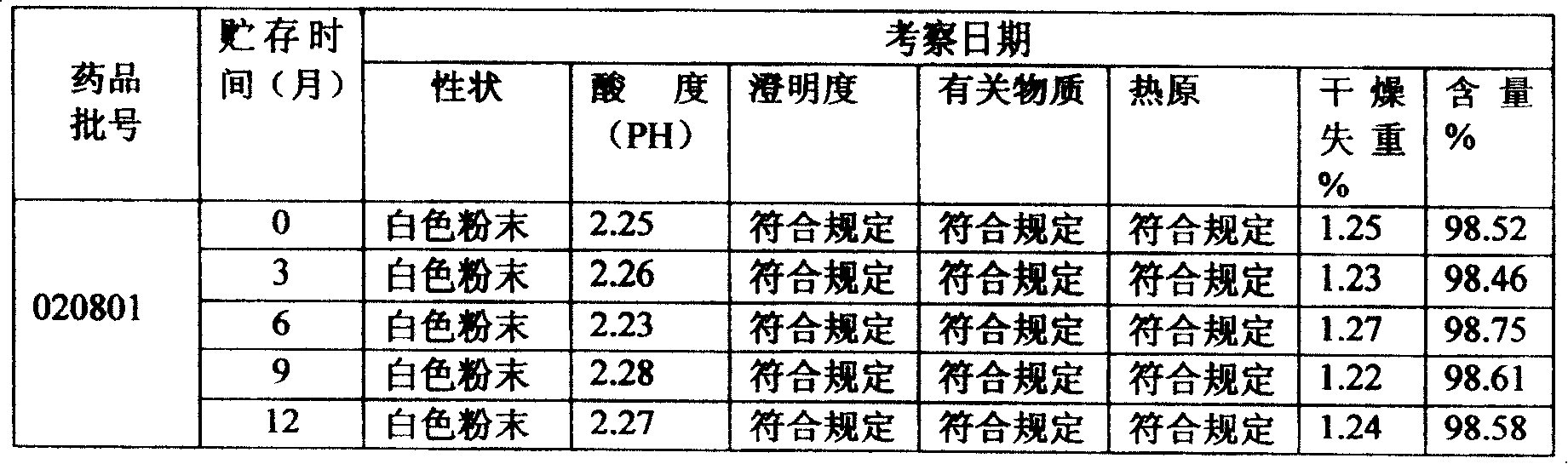

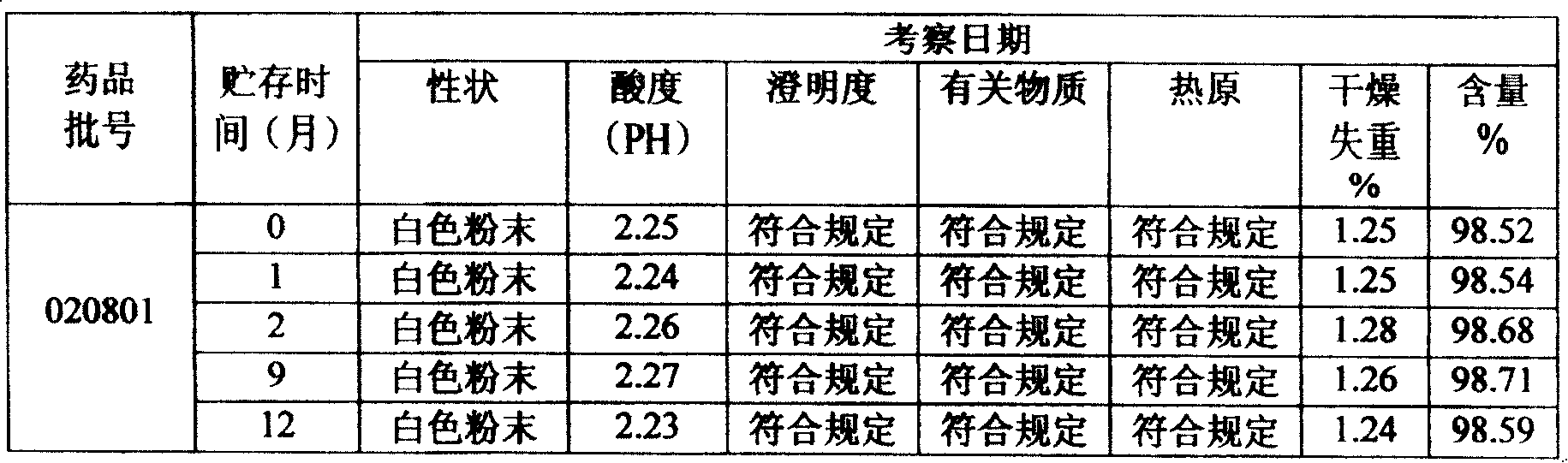

Examples

Embodiment 1

[0035] Embodiment 1, preparation tiopronin glycine freeze-dried powder injection

[0036] prescription:

[0037] Tiopronin 100g

[0038] Glycine 40g

[0039] Water for injection 1000ml

[0040] Preparation process: take 100 grams of tiopronin (content 98.6%), add 200 ml of water for injection to dissolve, weigh 40 g of glycine, add 100 ml of water for injection to dissolve, mix the above two solutions, stir, and make up the surplus water.

[0041] Under the pressure of 0.1MPa, filter with a 0.22μm microporous membrane, fill, freeze-dry, and seal.

Embodiment 2

[0042] Embodiment two, prepare tiopronin glycine freeze-dried powder injection

[0043] Tiopronin 100g

[0044] Glycine 50g

[0045] Water for injection 1000ml

[0046] Preparation process: take 100 grams of tiopronin (content 98.6%), add 200 ml of water for injection to dissolve, weigh 50 g of glycine, add 100 ml of water for injection to dissolve, mix the above two solutions, stir, and make up the surplus water.

[0047] Under the pressure of 0.1MPa, filter with a 0.22μm microporous membrane, fill, freeze-dry, and seal.

Embodiment 3

[0048] Embodiment three, prepare tiopronin glycine freeze-dried powder injection

[0049] Tiopronin 100g

[0050] Glycine 100g

[0051] Water for injection 1000ml

[0052] Preparation process: Weigh 100 grams of tiopronin (content 98.6%), add 200 ml of water for injection to dissolve, weigh 100 g of glycine, add 100 ml of water for injection to dissolve, mix the above two solutions, stir, and make up the remaining water.

[0053] Under the pressure of 0.1MPa, filter with a 0.22μm microporous membrane, fill, freeze-dry, and seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com