Fuel battery, its catalyst layer and manufacturing method of said catalyst layer

A catalyst layer and fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve problems such as insufficient contact between catalyst and fuel, decreased catalyst activity, fuel flow blockage, etc., to increase catalyst performance and reduce consumption , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

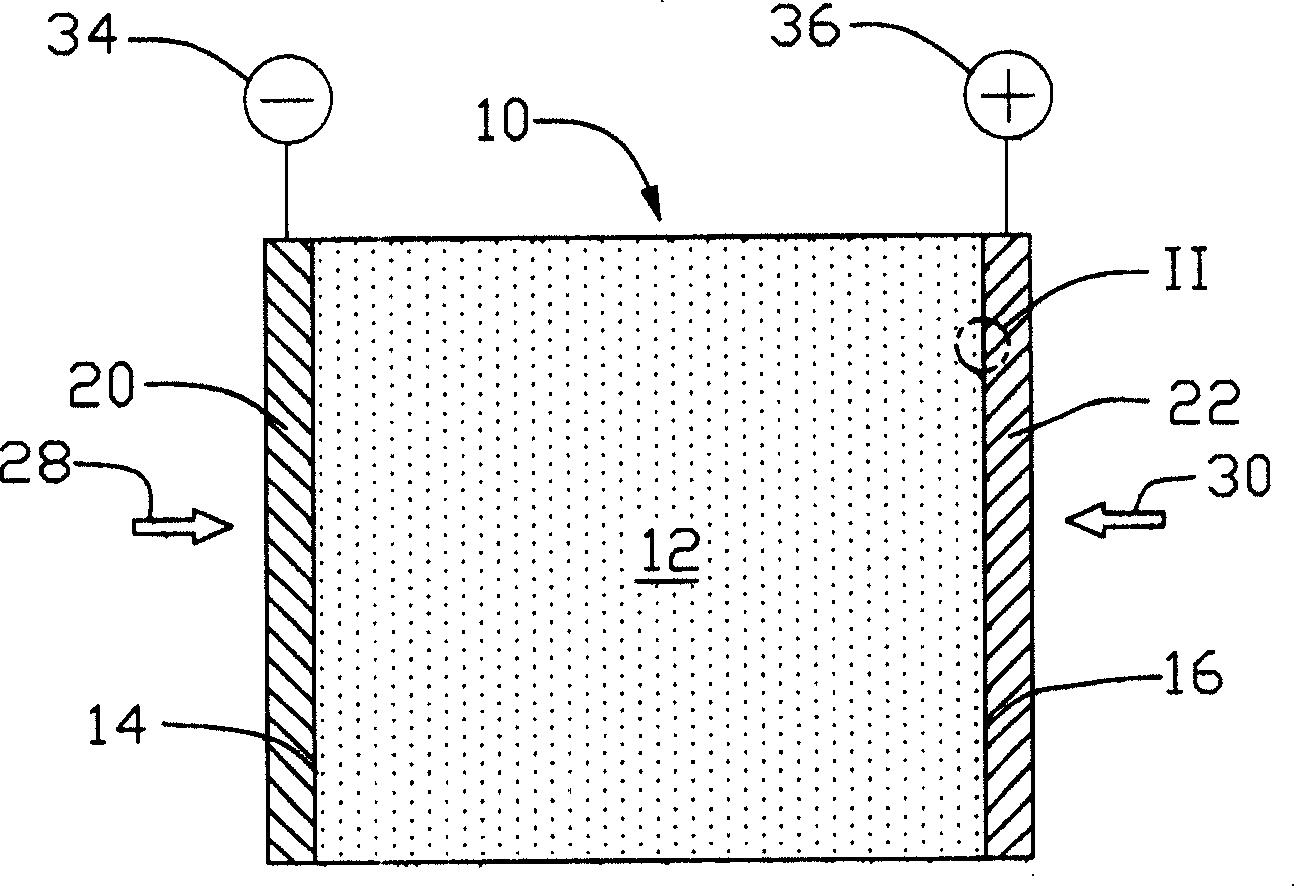

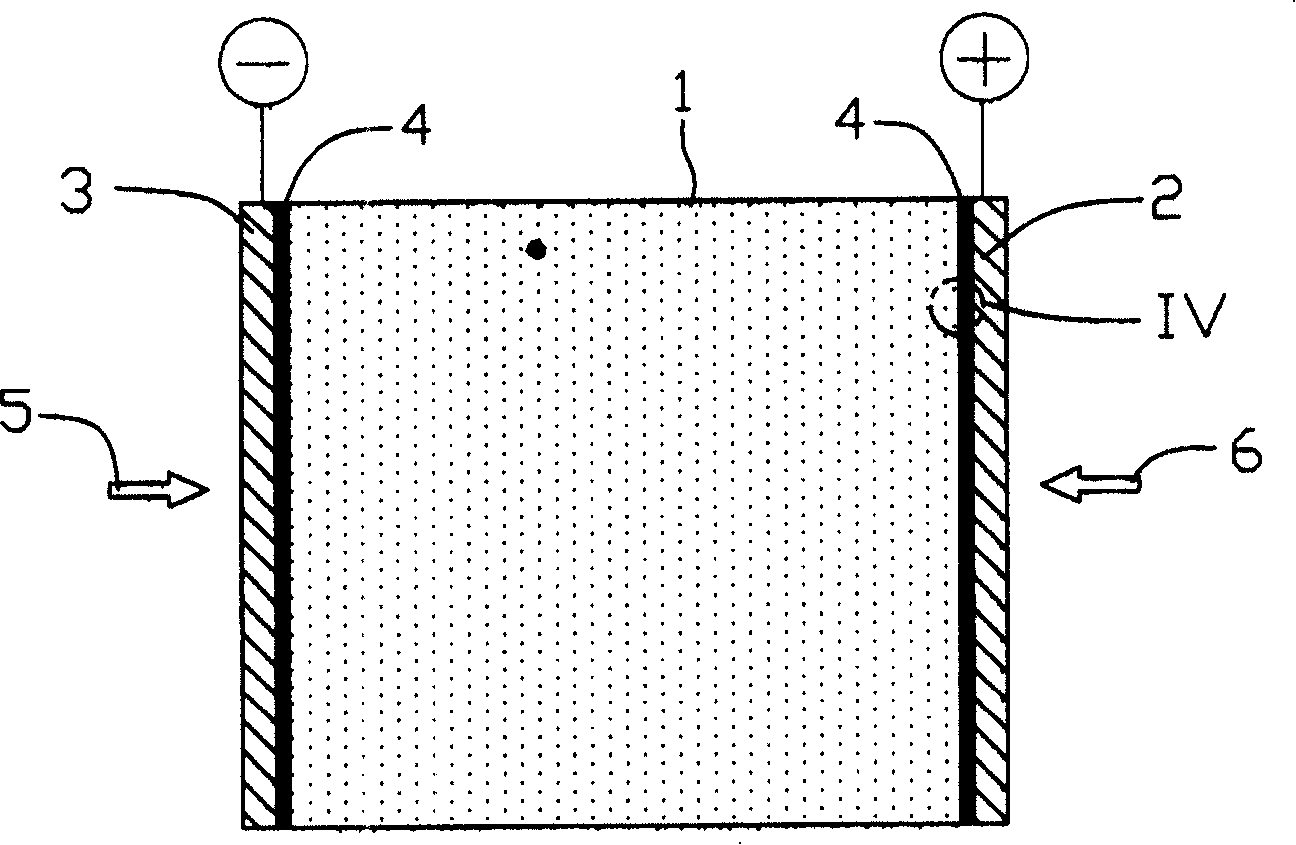

[0022] see image 3 , is a schematic structural view of a fuel cell using the catalyst layer of the present invention. The fuel cell includes an electrolyte 1 and an anode 2 and a cathode 3 respectively located on both sides of the electrolyte 1 . A catalyst layer 4 is formed on the surfaces of the anode 2 and the cathode 3 which are in contact with the electrolyte 1 . The catalyst layer 4 includes a tubular support (not shown) and a catalyst formed on the tubular support. The electrolyte used in the fuel cell of the present invention is selected from proton exchange membranes, solid oxides, phosphoric acid or alkaline solutions, etc., wherein the proton exchange membranes can be selected from perfluorosulfonic acid membranes, polystyrenesulfonic acid membranes, polytrifluorosulfonic acid membranes, Styrene sulfonic acid membrane, phenolic resin sulfonic acid membrane, hydrocarbon membrane, etc., solid oxides include zirconia, etc., alkaline solution is selected from NaOH or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com