Inward convex integrated throttle valve

A throttle valve, an integrated technology, applied in the field of throttle valve, can solve the problems of difficult processing and assembly, many consumables of split throttle valve, etc., saving manpower and energy consumption, reducing complex processing process, stable and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

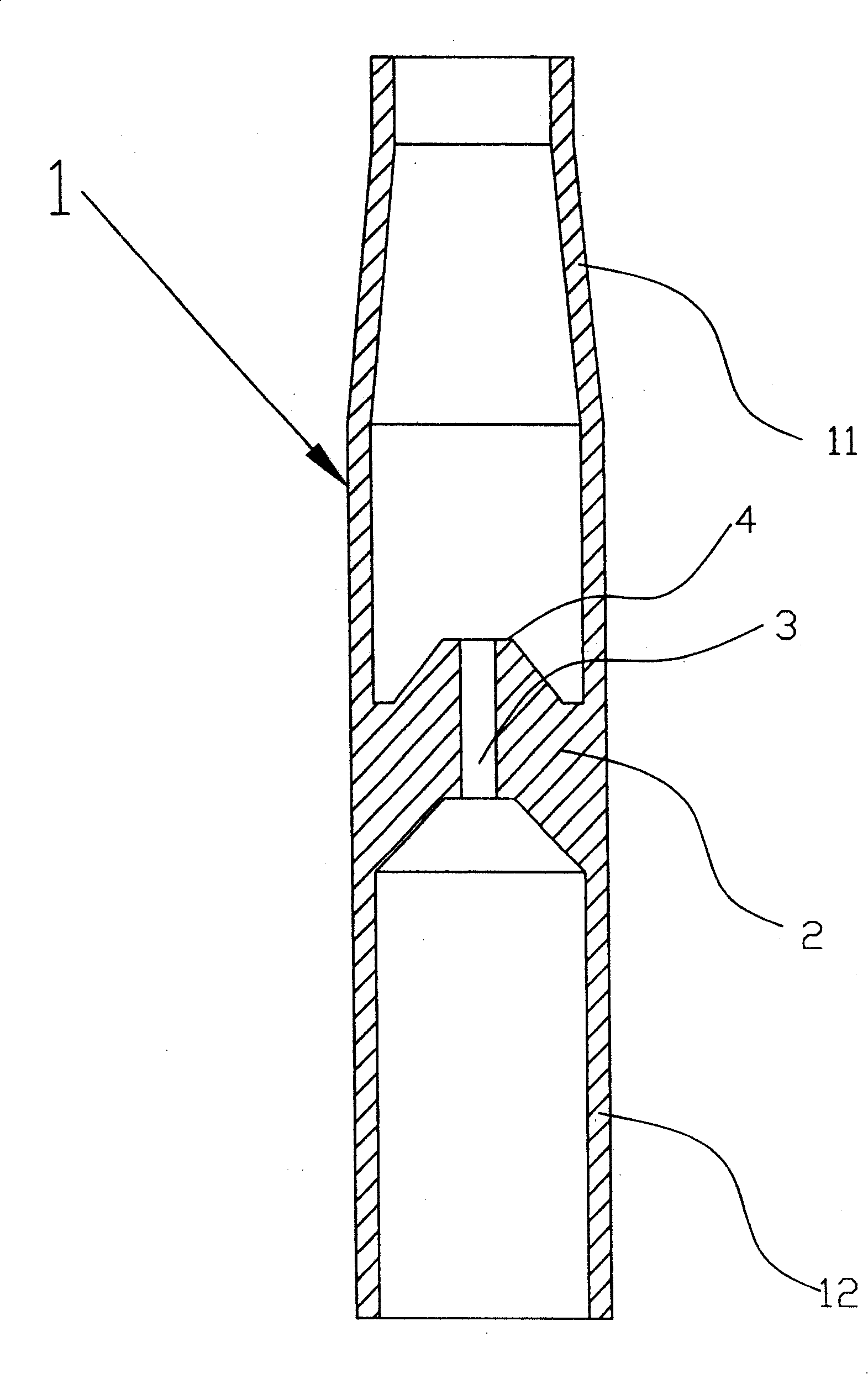

[0022] refer to figure 1 , This embodiment includes a valve body 1 and a valve core 2, and its structural features are: the valve body 1 and the valve core 2 are extruded from a copper tube, forming an integral structure; the two ends of the formed throttle valve are the valve body 1. A valve core 2 is formed in the middle; a ring platform 4 with an orifice 3 is formed in the center of the valve core 2, and the periphery is connected with the valve body 1 as a whole.

[0023] In this embodiment, the valve body 1 and the valve core 2 are made of a section of red copper tube, the valve core 2 is located in the middle of the red copper tube, and the two ends of the red copper tube form the valve body 1 . The front of the valve core 2 is convex and is frustoconical, its axial section is an isosceles trapezoid, the end face of the ring platform 4 is circular, and the throttle hole 3 is located at the center of the ring platform 4; The back is concave and its shape is complementary...

specific Embodiment 2

[0024] The characteristics of this specific embodiment are: the two ends of the valve core 2 are platform-shaped, the valve body is cylindrical, the diameter of the cylinder is large and small, and the shape of the interface at both ends of the cylinder matches the matching position of the whole machine. , according to the needs of the whole machine. The position of the valve core in the cylinder is determined according to the matching of the whole machine. The rest are the same as in Example 1.

[0025] The manufacturing method of the present invention is as follows: prepare the red copper tube as required, place the red copper tube in a special mold, extrude it at one time with an extruder, and use a machine to extrude from both ends of the copper tube to the middle during extrusion, The valve core 2 is formed by extruding the inner cavity of the copper tube. The size and shape of the valve core 2 can be set as required. The size and shape of the valve core 2 and the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com